Calibration equipment and calibration method for gas-liquid ratio tester

A technology for calibrating equipment and testers, used in pump testing, mechanical equipment, liquid variable capacity machinery, etc., and can solve problems such as design deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

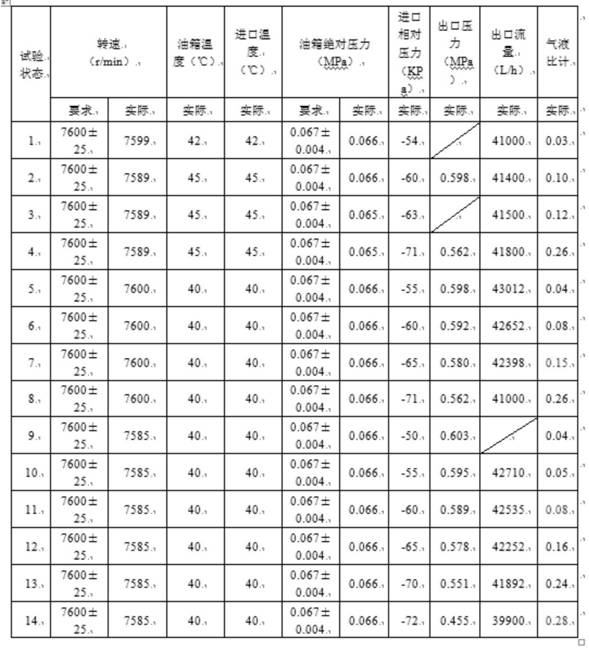

Examples

Embodiment Construction

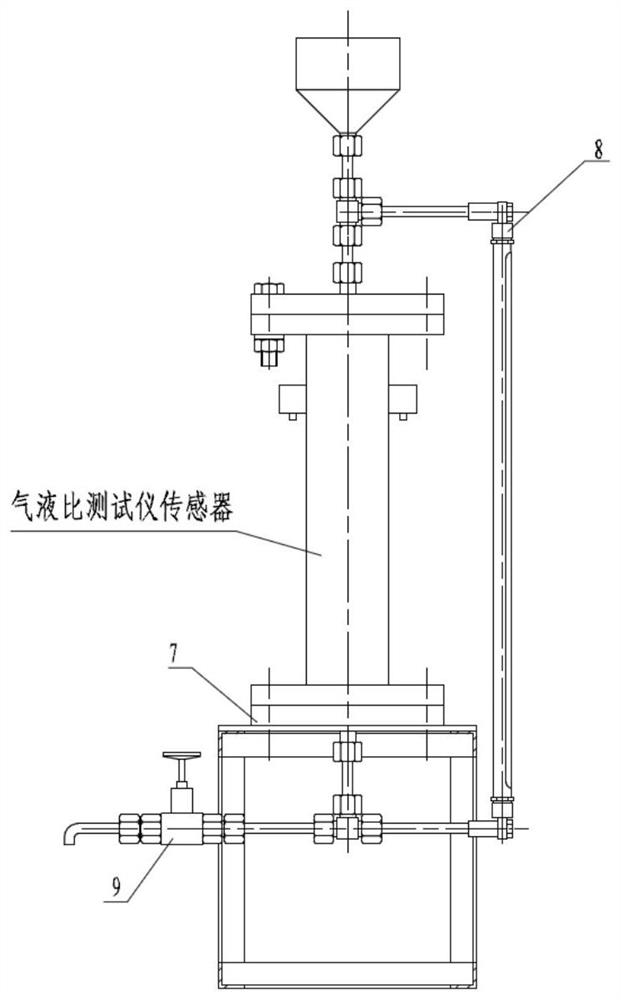

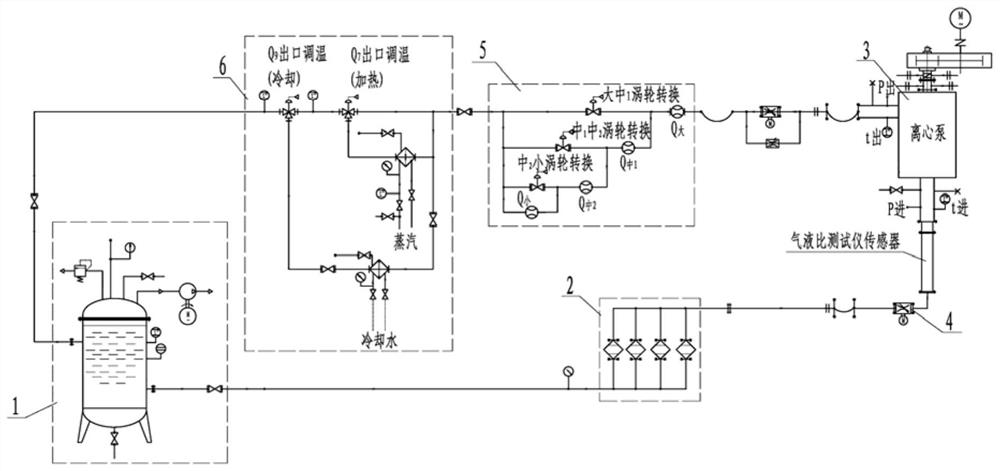

[0026] Below in conjunction with accompanying drawing, the present invention is further described:

[0027] A calibration device for a gas-liquid ratio tester, comprising a negative pressure oil tank 1, an oil filter group 2, an oil pump group 3, a pressure adjustment and measurement mechanism 4, a flow measurement mechanism 5, and a temperature adjustment and measurement mechanism 6. Schematic see figure 1 .

[0028] Among them, the negative pressure oil tank 1 adopts a special oil tank conforming to GB150-1998 "Steel Pressure Vessel", cooperates with a vacuum pump and a regulating valve to ensure that the pressure of the oil tank is 0.067±0.004MPa (absolute pressure); the outlet of the negative pressure oil tank 1 is connected to the oil filter group 2, the oil filter Group 2 adopts stainless steel filter elements to ensure the cleanliness of the working medium; the outlet of oil filter group 2 is connected to the pressure regulation and measurement mechanism 4, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com