Mixing and drying integrated particle material treatment device

A technology for granular materials and processing devices, applied in the field of granular material processing devices, can solve the problems that the drying machine cannot mix materials, the mixing machine cannot dry materials, etc., so as to increase the gap, improve the mixing efficiency, and reduce the heating energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

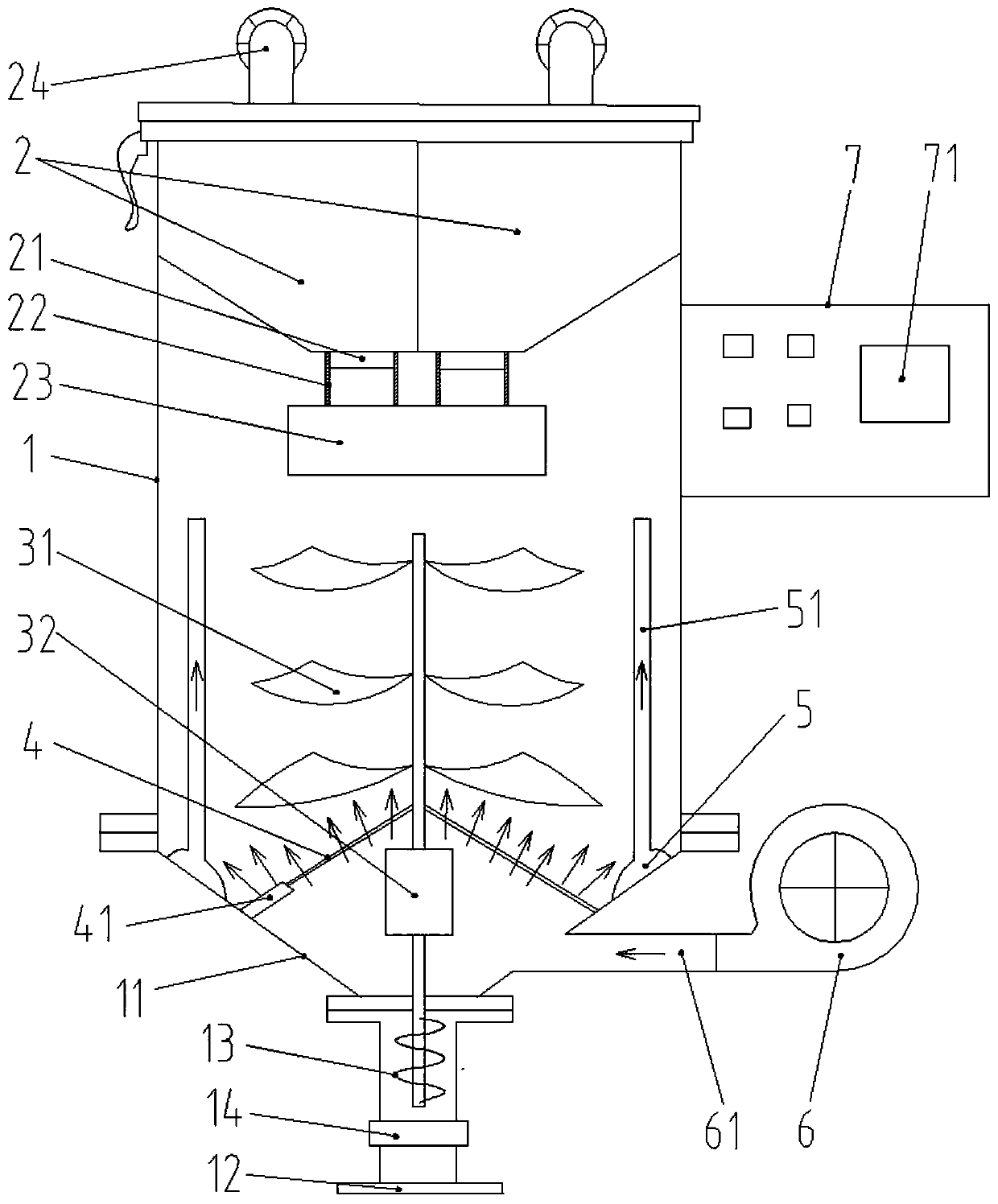

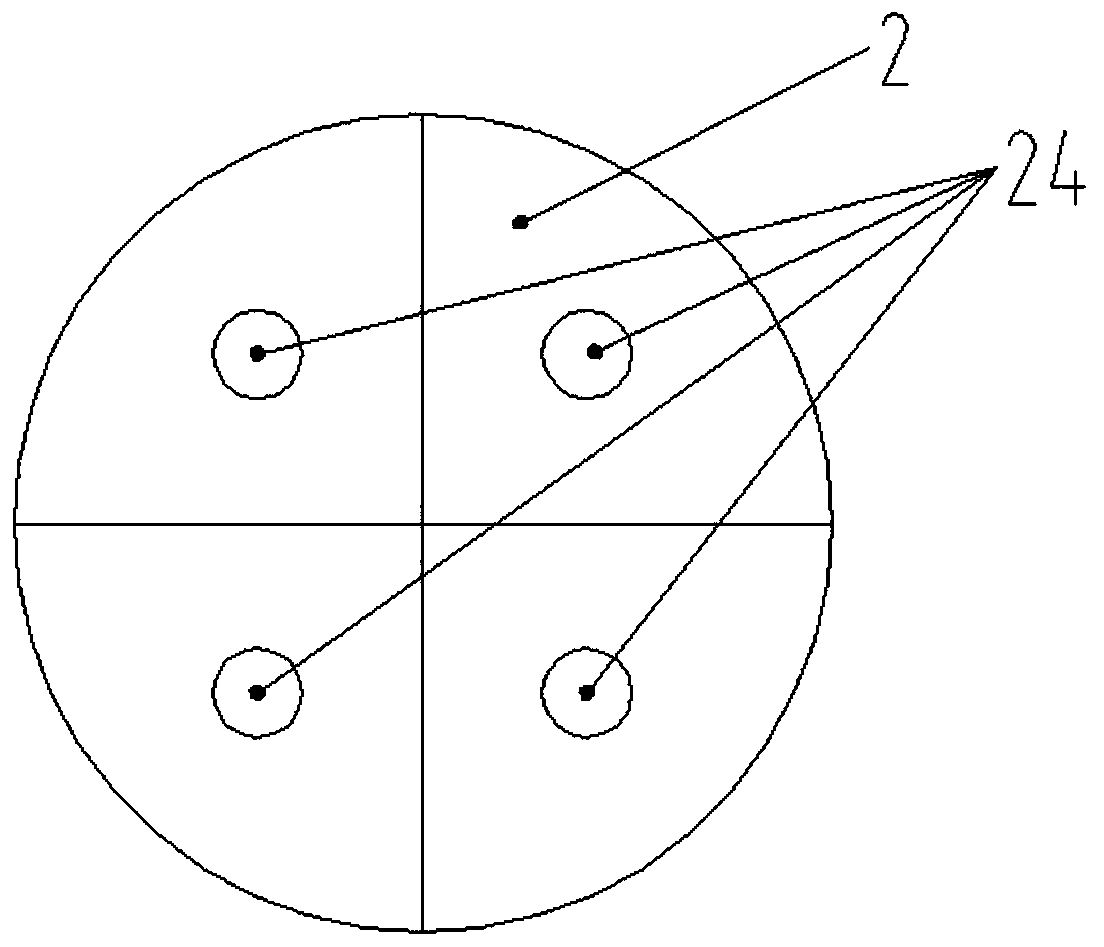

[0031] This embodiment is basically as figure 1 Shown: a granular material processing device integrating mixing and drying, including a mixing tank 1 and several storage tanks 2. The mixing tank 1 is arranged vertically, preferably in a cylindrical shape, and the mixing tank 1 is provided with an inlet, an outlet 12, an air inlet and an air outlet (not shown in the figure). The material storage barrel 2 is located above the drying material barrel. In this embodiment, the number of material storage barrels 2 is four for illustration. figure 2 It can be seen that the overall shape of the four material storage tanks 2 is cylindrical, and each material storage tank 2 is connected with a material suction device 24, and the materials are directly sucked into each material storage tank 2 through the adsorption force of the material suction device 24. There is no need to manually add materials into each storage tank 2 .

[0032] The discharge port of each material storage tank 2 is...

Embodiment 2

[0046] The difference between the present embodiment and the first embodiment is that the blanking amount control unit of this implementation includes a regulating valve 21, but no leakage pipe 22, a weighing container 23, a weight sensor, a weight comparator, and a blanking electromagnetic valve are not provided. . Although thus the structure can be simplified and the volume of the processing device can be reduced, but the proportioning accuracy is relatively low, and it is suitable for occasions where the requirement for the proportioning accuracy is not particularly high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com