Nitrogen/chlorine (argon/chlorine) mixing and proportioning system and operation method thereof

A technology of nitrogen and chlorine mixers, which is applied in the direction of mixing methods, gas and gas/steam mixing, mixers, etc., can solve the problems of personal injury, affecting service life, low proportioning accuracy, etc., and achieves convenient installation, operation, and prolongation The effect of improving the service life and improving the proportioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

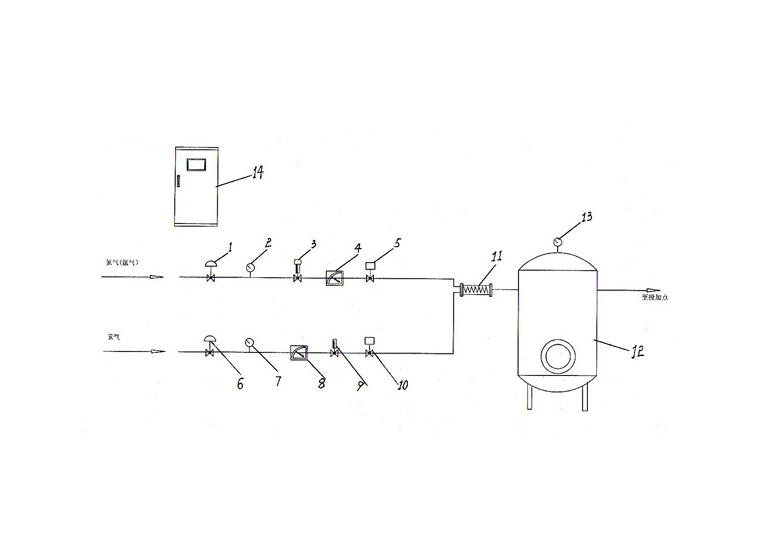

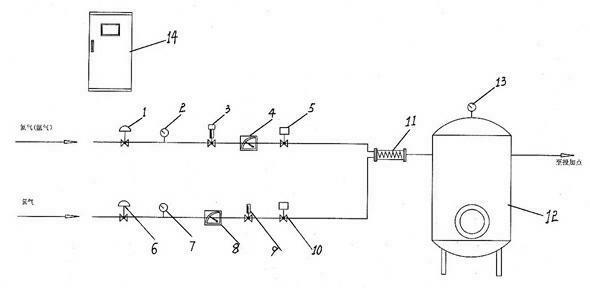

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

[0016] The present invention is composed of nitrogen (argon) operating equipment, chlorine operating equipment, nitrogen-chlorine (argon-chlorine) mixer (11), mixed gas storage tank (12) and PLC control cabinet (14), nitrogen (argon) operating equipment The nitrogen (argon) pressure reducing valve (1), nitrogen (argon) pressure sensor (2), nitrogen (argon) electric linear flow regulating device (3), nitrogen (argon) flow measuring device (4) are sequentially composed , nitrogen (argon) electric ball valve (5); the chlorine gas operation equipment consists of a chlorine gas pressure reducing valve (6), a chlorine gas pressure sensor (7), a chlorine gas flow detection device (8), a chlorine gas manual flow adjustment device (9), The chlorine gas electric ball valve (10) is composed of; the nitrogen (argon) operating equipment and the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com