Method for promoting plastic additive distributing precision and device thereof

A technology of proportioning accuracy and additives, applied in the field of plastic processing, can solve the problems of inconsistent content ratio of recycled materials, inability to meet product quality requirements, affecting product quality stability, etc., to improve overall production efficiency, significant technological advancement and work. Practicality, avoiding the effect of unstable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

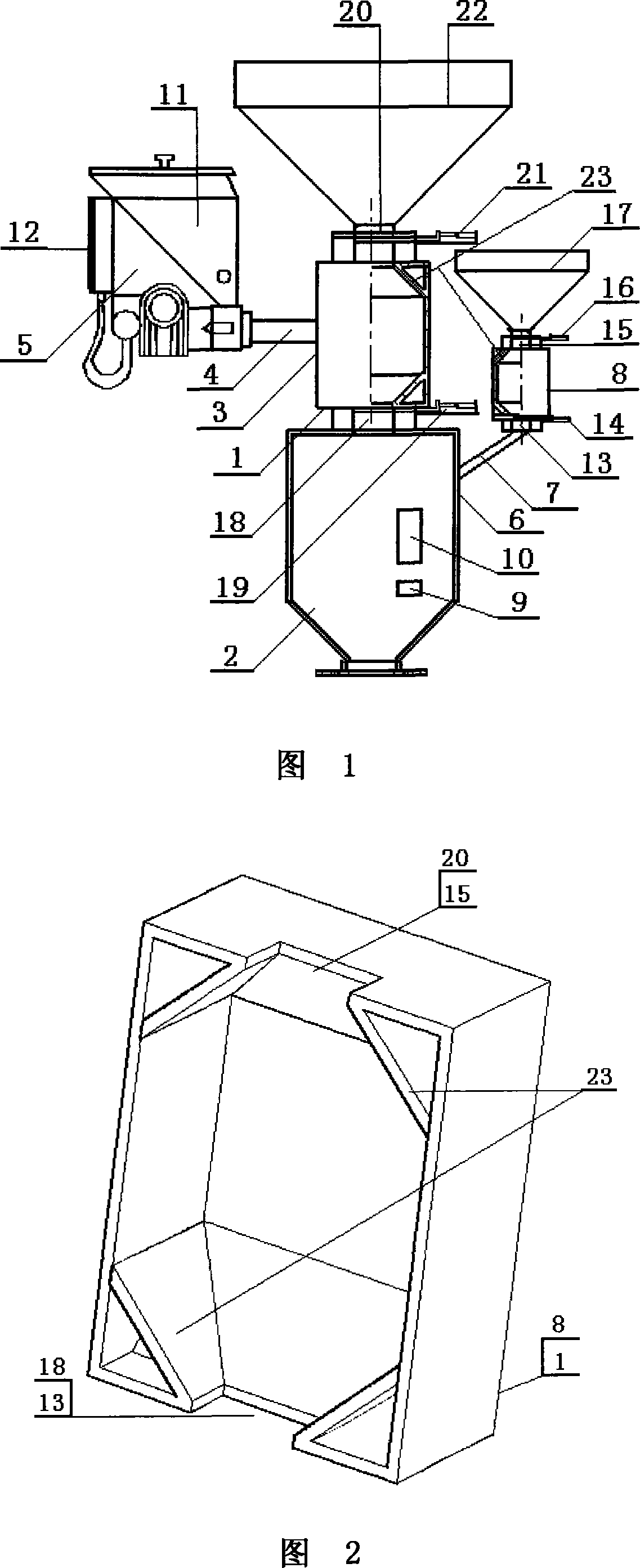

[0022] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0023] In Fig. 1 and Fig. 2, the main body of the device for improving the proportioning accuracy of plastic additives of the present invention is composed of a constant-volume meter 1 and a mixer 2 with a rated capacity, and is characterized in that: 3 on the side wall of the constant-volume meter 1 A special feed port 4 for plastic additives is provided on the top, and a volumetric meter 5 is provided on the special feed port 4; the near upper side wall 6 of the mixer 2 is provided with a recycled material inlet as required 7, and a recycle material fixed container 8 is provided on the recycle material inlet 7, and a material level detection sensor 9 is also provided on the outer side wall 6. The electric controller 10 is arranged on the side of the mixer. Wherein: the volumetric measuring instrument 5 is provided with an additive storage bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com