Intelligent liquid raw material proportioning control system

A liquid raw material, ratio control technology, applied in various fluid ratio control, control of the mixing ratio of fluids at different temperatures, etc., can solve the problems of enterprises prone to safety problems, large waste of raw materials, and low accuracy of addition, etc. The effect of high income, low investment and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

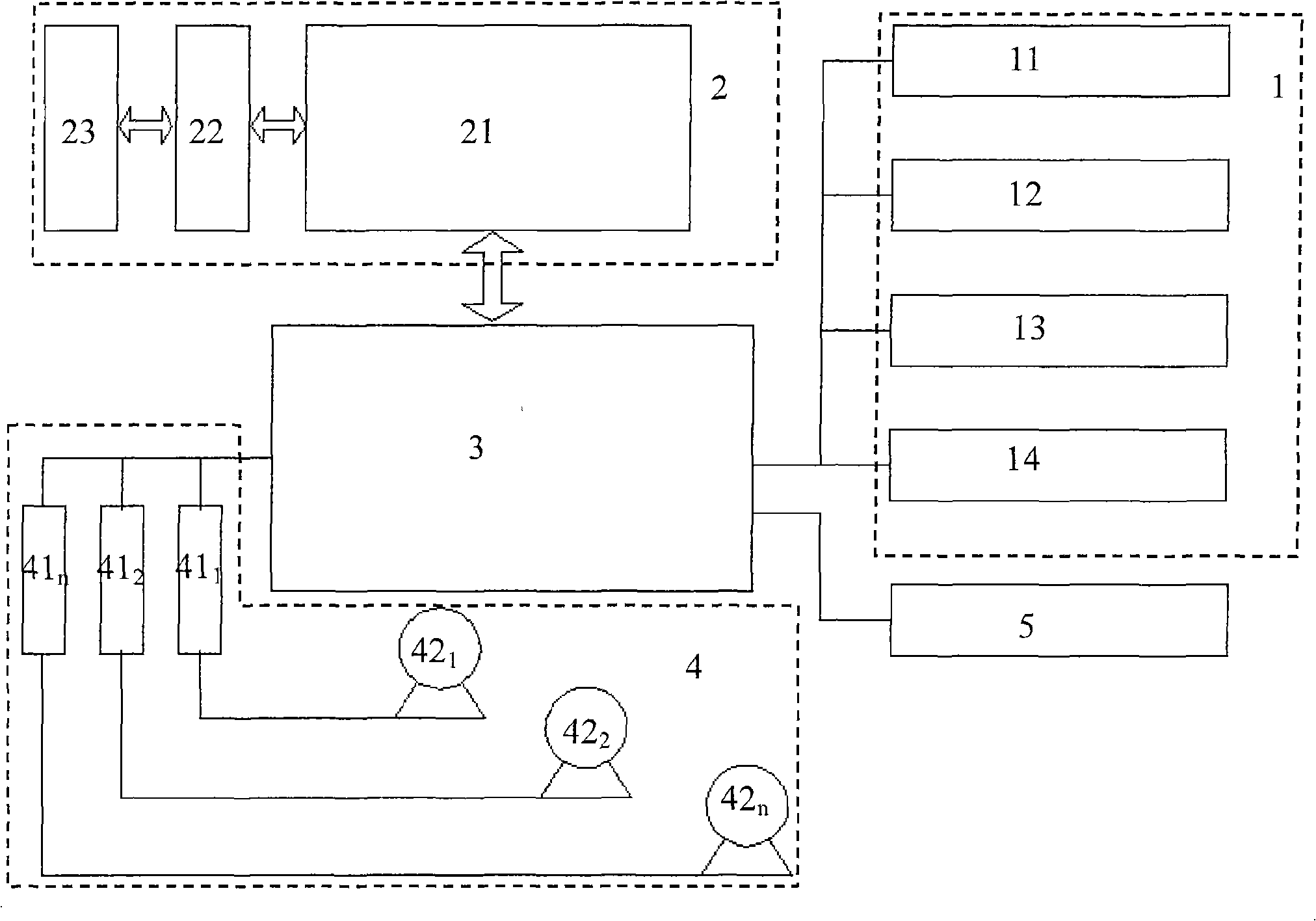

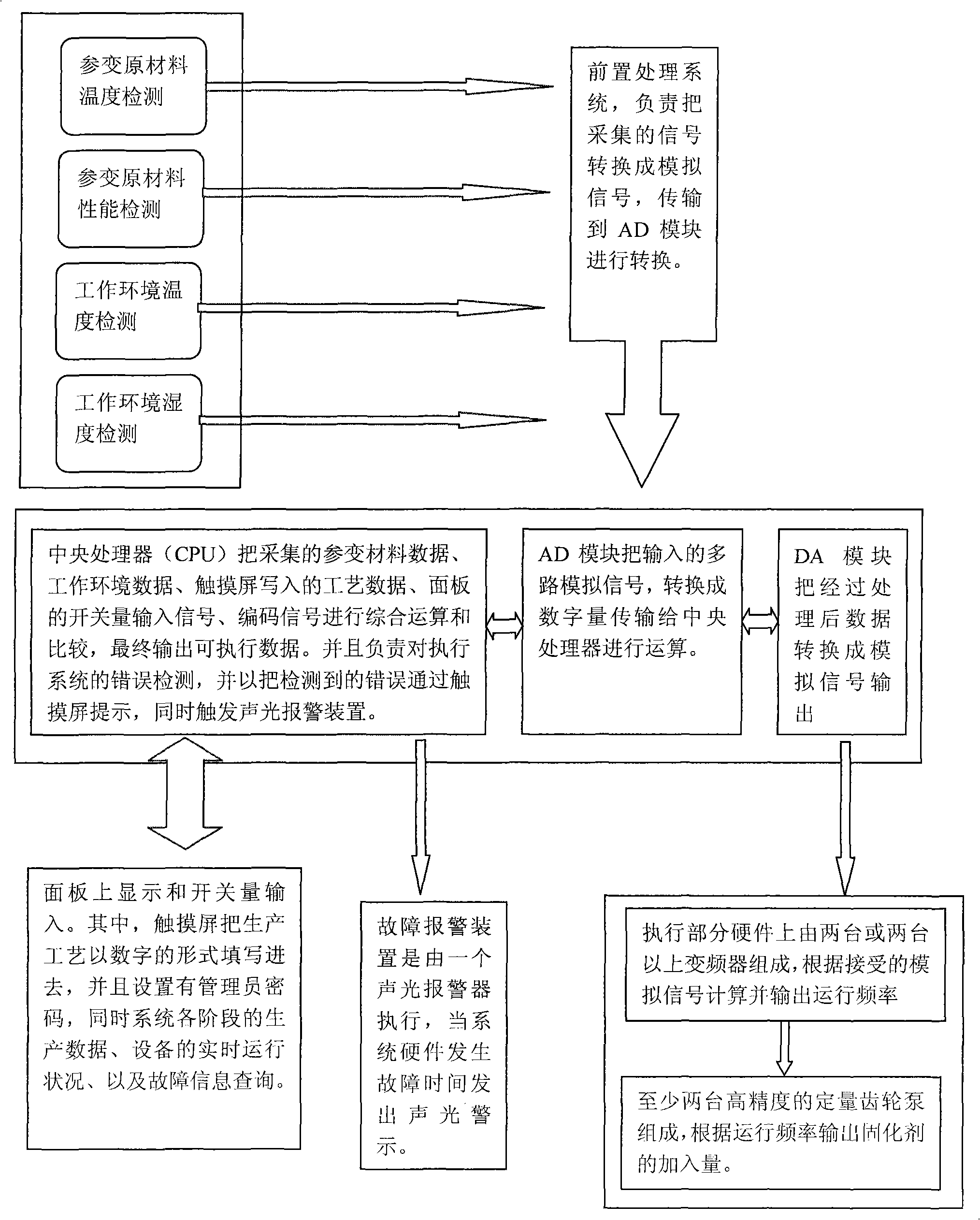

[0020] Example: such as figure 1 with figure 2 As shown, an intelligent liquid raw material proportioning control system includes a parameter acquisition module 1 for detecting raw materials and environmental parameters, a preprocessing system for preprocessing the data of the parameter acquisition module 1, an actuator 4, and a preprocessing system for preprocessing the data of the parameter acquisition module 1. Process the signal of the processing system and output the execution signal to the central processing system 3 of the actuator 4, the display setting panel 2 for displaying and setting the parameters of the central processing system 3, and the system failure alarm device for alarming the system failure 5.

[0021] The parameter collection module 1 includes a parametric raw material temperature sensor 11 , a parametric raw material performance detection sensor 12 , an ambient humidity detection sensor 13 and an ambient temperature detection sensor 14 .

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com