Mass flow high density structure flow entire-tailing cemented filling technology

A technology of cemented filling and full tailings, which is used in filling materials, safety devices, mining equipment, etc., can solve the problems of poor proportioning control force, inability to self-flow filling, insufficient filling and pulping capacity, etc., and achieves high proportioning accuracy, Reasonable strength and structure of filling body and the effect of reducing filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

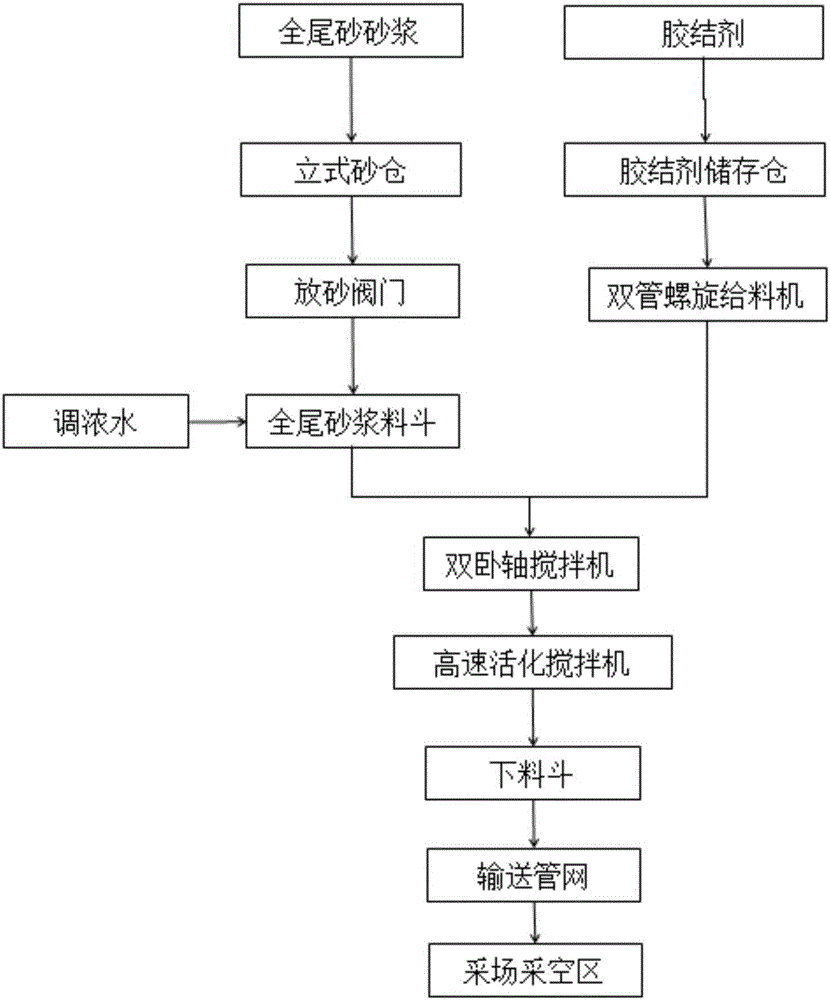

[0035] The full tailings cemented filling process with large flow and high concentration structured flow includes the following steps:

[0036] (1) Overall filling configuration:

[0037] There are 2 sets of filling slurry preparation systems in the filling station, and the preparation capacity of each system is 160~180m 3 / h, each system can run independently for 10-12 hours, satisfying 24-hour filling; a single filling system consists of 2 vertical sand bins, 1 cement storage bin, 1 set of secondary mixing equipment, 2 filling drills Hole and matching control system;

[0038] (2) Full tailings storage and pulping feed:

[0039] The tailings slurry in the concentrator is concentrated by the thickener, so that the underflow concentration of the thickener can be increased to 45%; the full tailings slurry is transported to the vertical full tailings storage bin of the filling station through the sand conveying pipe; the vertical sand storage bin set up by the filling system T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com