Shaftless spiral automatic proportioning concrete mixing conveyor

An automatic proportioning and shaftless screw technology, which is applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of inability to achieve continuous and stable preparation of concrete, low stability and precision of batching ratio, and inaccurate proportioning, etc. problems, to achieve the effect of reducing equipment length, easy implementation, and high proportioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

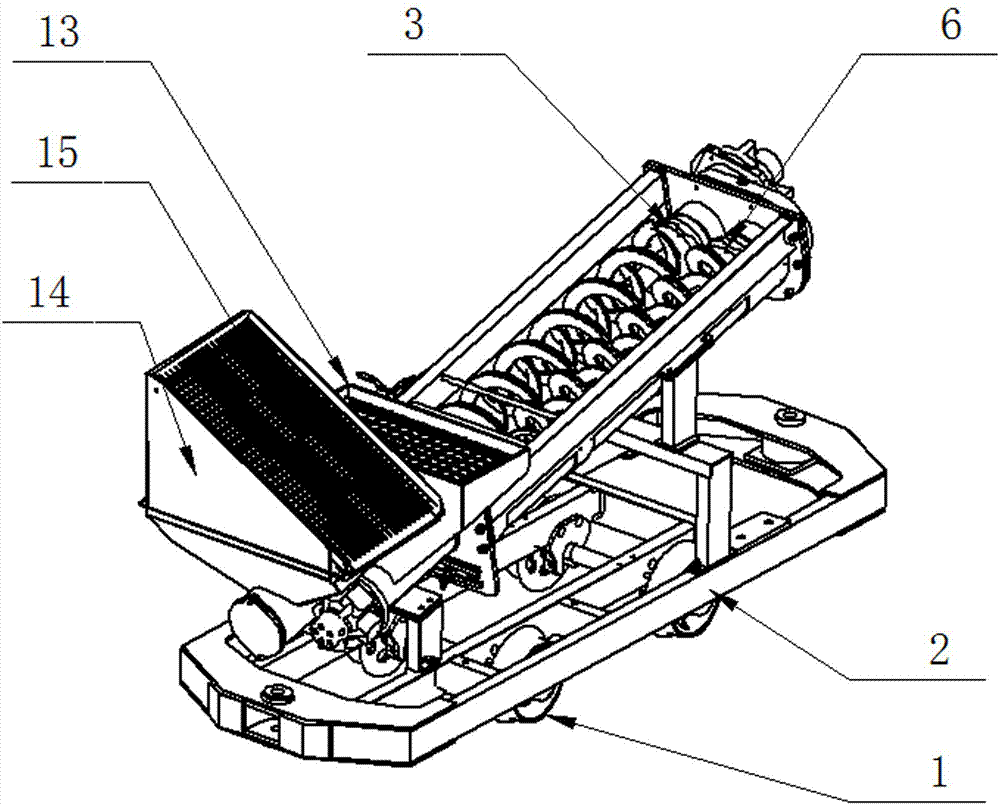

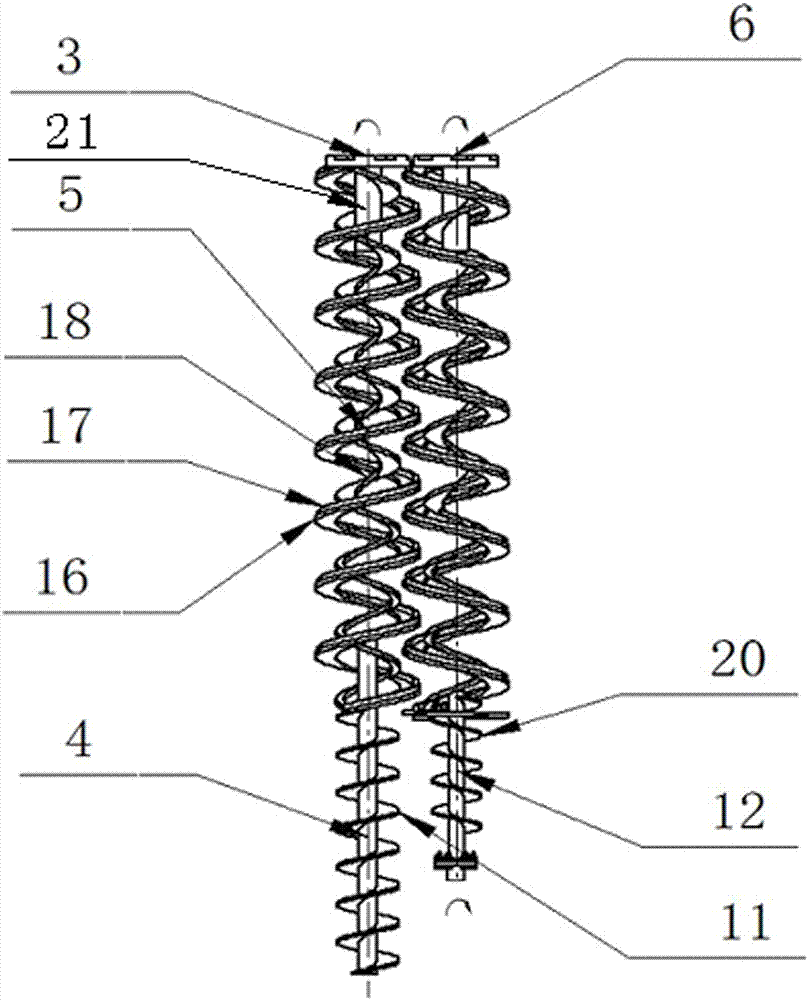

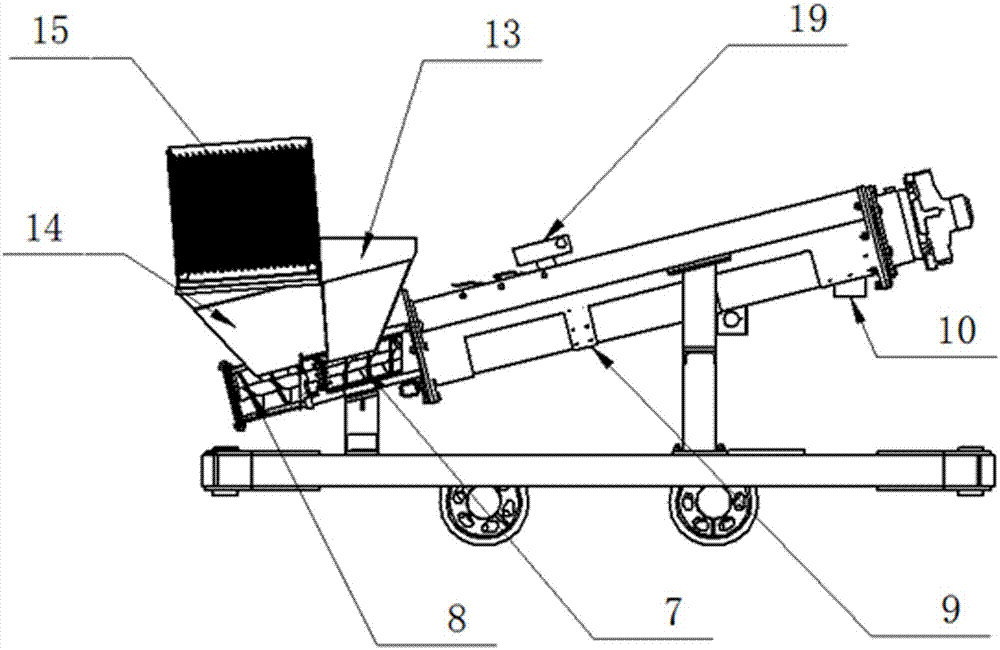

[0018] Referring to each figure, the shaftless spiral automatic proportioning concrete mixing conveyor includes a walking wheel 1, a mine car chassis 2, and a conveying and mixing system. The conveying and agitating system includes a stirring channel 9, a conveying and agitating driving shaft 3 and a conveying and agitating driven shaft 6, the conveying and agitating driving shaft 3 forms an angle of 0 to 25 degrees with the horizontal plane, and the conveying and agitating driving shaft 3 and the conveying and agitating driven shaft 6 are relatively parallel Arrangement, one end of the conveying and stirring driving shaft 3 is supported on the inner wall of the stirring channel 9 through a bearing, and one end of the conveying and stirring driving shaft 3 is connected to the power source; The feeding section 4 and the mixing section 5, the conveying and mixing system is divided into a gravel feeding channel 8 and a mixing channel 9 according to the conveying direction from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com