Crank drive

A crank-connecting-rod mechanism and crank technology are applied in mechanical equipment, combustion engines, machines/engines, etc., which can solve the problems of inability to realize the structural form and the need for a large crank-connecting-rod mechanism, and achieve compact structure, compact structure, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

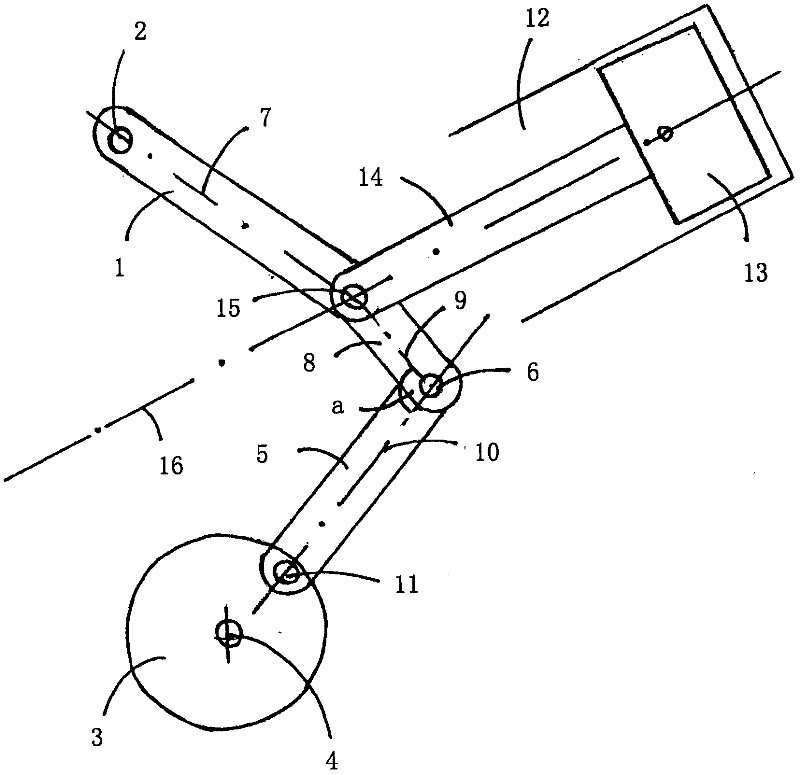

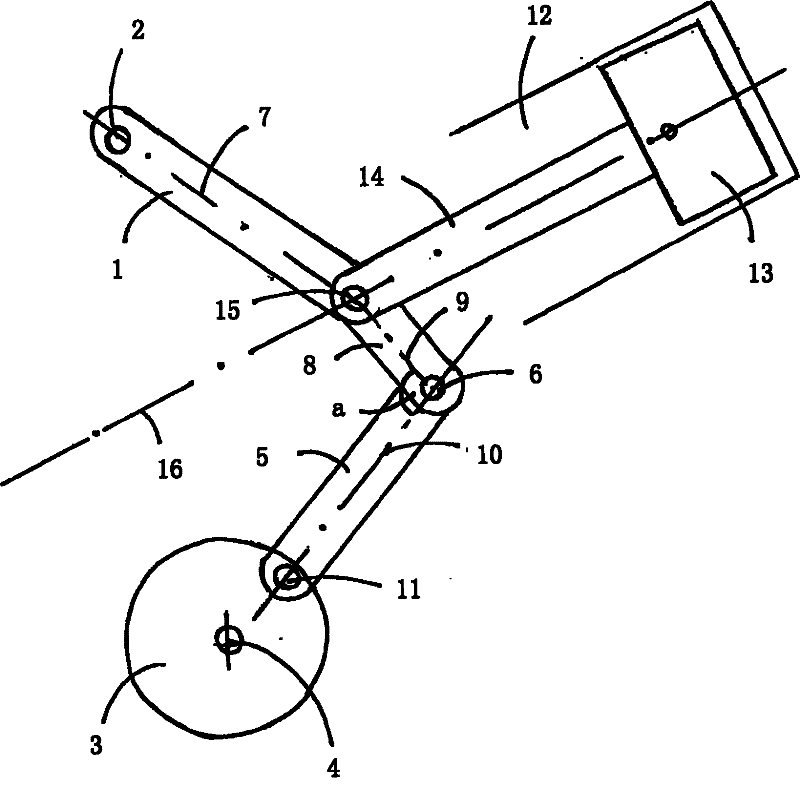

[0026] figure 1 The crank-and-link mechanism depicted in includes a rocker 1 , one end of which is mounted in a fixed manner with its rocker axis 2 on a frame, not shown. The crank linkage mechanism is driven by a crank 3, which is also mounted on the above-mentioned frame in a manner that its axis 4 is fixed. The orientation of the rocker axis 2 and the axis 4 are parallel to each other. The connecting rod 5 is connected via a joint 6 to a section 8 which is bent towards the longitudinal axis 7 of the rocker 1 .

[0027] This curved section 8 is inclined at a fixed angle to the connecting rod 5 compared to the longitudinal axis 7 of the rocker 1 and is preferably produced in one piece with the rocker 1 . Thus, an angle a that varies with the rotational movement of the crank 3 is formed between the longitudinal axis 9 of the section 8 bent towards the connecting rod 5 and the longitudinal axis 10 of the connecting rod 5 . During the rotational movement of the crank 3 , this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com