Rotary compressor

A technology of rotary compressors and compression mechanisms, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., which can solve problems such as deterioration of bearing lubrication conditions, decreased rigidity of countershafts, and increased deflection, and achieves deflection Effects of reduced curvature, increased rigidity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

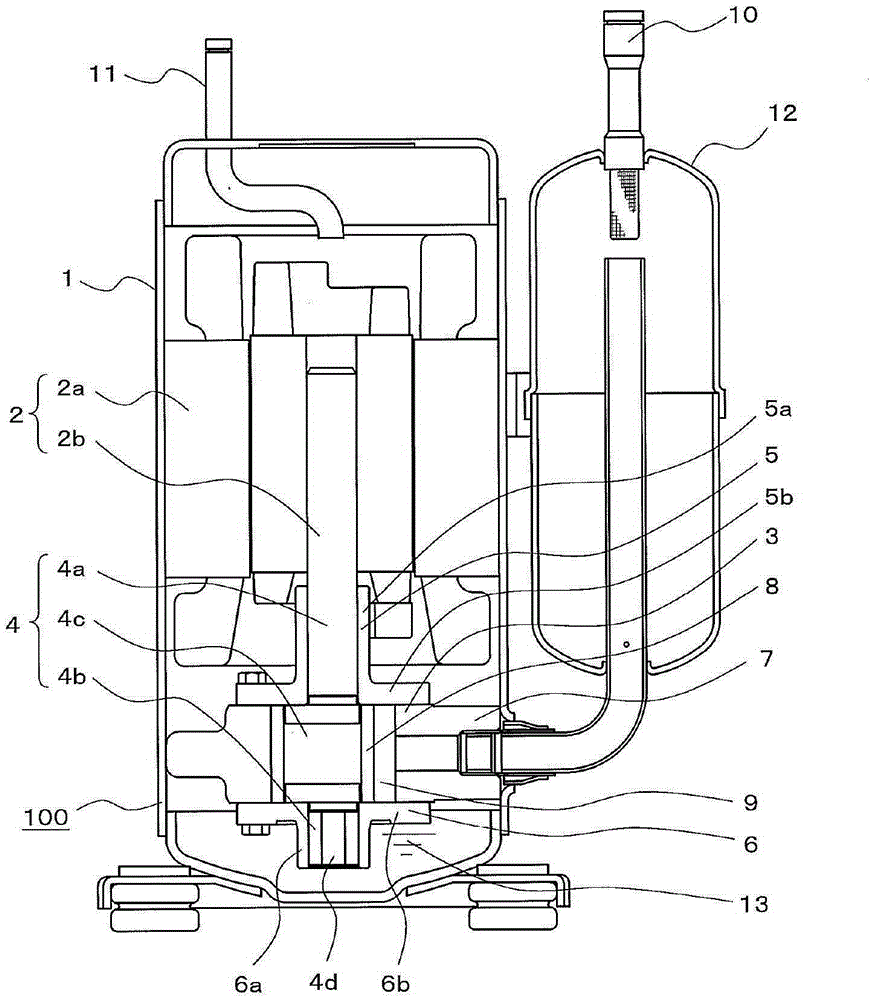

[0026] figure 1 It is a schematic configuration diagram showing the rotary compressor 100 according to Embodiment 1 of the present invention.

[0027] In Embodiment 1, as the rotary compressor 100 , a vertical rotary hermetic electric compressor is shown as an example. The rotary compressor 100 is used in a refrigeration cycle of an air conditioner or the like.

[0028] Such as figure 1 As shown, in the rotary compressor 100 , a compression mechanism unit 3 for compressing a refrigerant is disposed at the lower portion and an electric motor (motor unit) 2 for driving the compression mechanism unit 3 is disposed at the upper portion in a sealed container 1 with a high-pressure atmosphere. The electric motor 2 has a stator 2 a and a rotor 2 b, and is configured to rotate a crankshaft 4 which is a rotating shaft fixed to the rotor 2 b, and to drive the compression mechanism unit 3 by the crankshaft 4 .

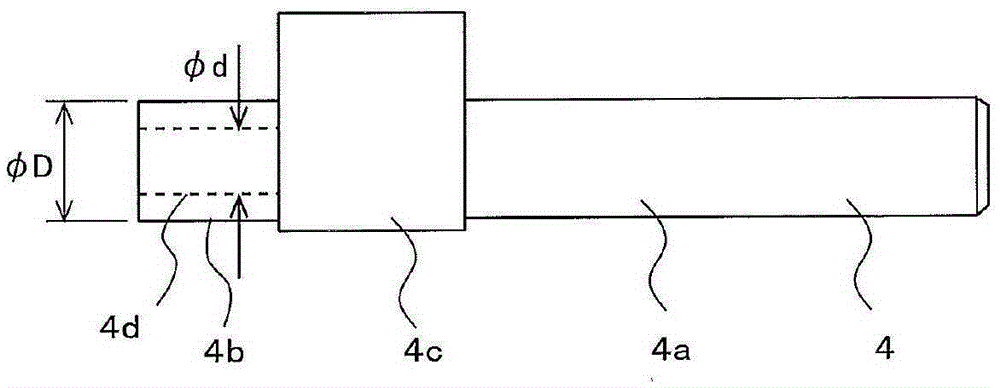

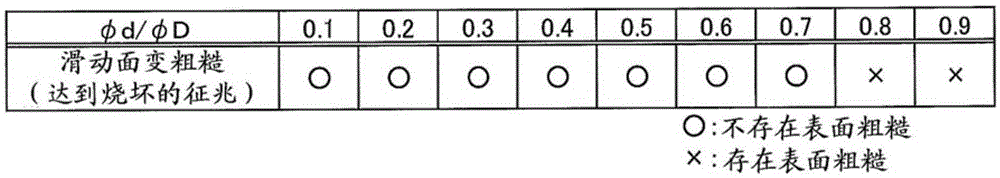

[0029] The crankshaft 4 has: a main shaft 4a fixed to the rotor 2b of the...

Embodiment approach 2

[0060] Figure 5 It is a refrigerant circuit diagram showing an example of the refrigeration cycle apparatus 200 to which the rotary compressor 100 according to Embodiment 2 of the present invention is applied.

[0061] Figure 5 The illustrated refrigeration cycle device 200 forms a refrigeration cycle circuit in which a rotary compressor 100 , a condenser 201 , an expansion valve 202 , and an evaporator 203 are connected by refrigerant piping. Furthermore, the refrigerant flowing out of the evaporator 203 is sucked into the rotary compressor 100 and compressed to become high temperature and high pressure. The high-temperature and high-pressure refrigerant is condensed in the condenser 201 to become a liquid. The liquid refrigerant decompresses and expands in the expansion valve 202 to become a low-temperature and low-pressure gas-liquid two-phase state, and the gas-liquid two-phase refrigerant exchanges heat in the evaporator 203 .

[0062] The rotary compressor 100 can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Longitudinal modulus of elasticity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com