Guide bar device for yarn pressing warp knitting machine

A technology of warp knitting machine and bar, applied in the field of bar device of press-type warp knitting machine, can solve the problems of missing needles, impact, complicated movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

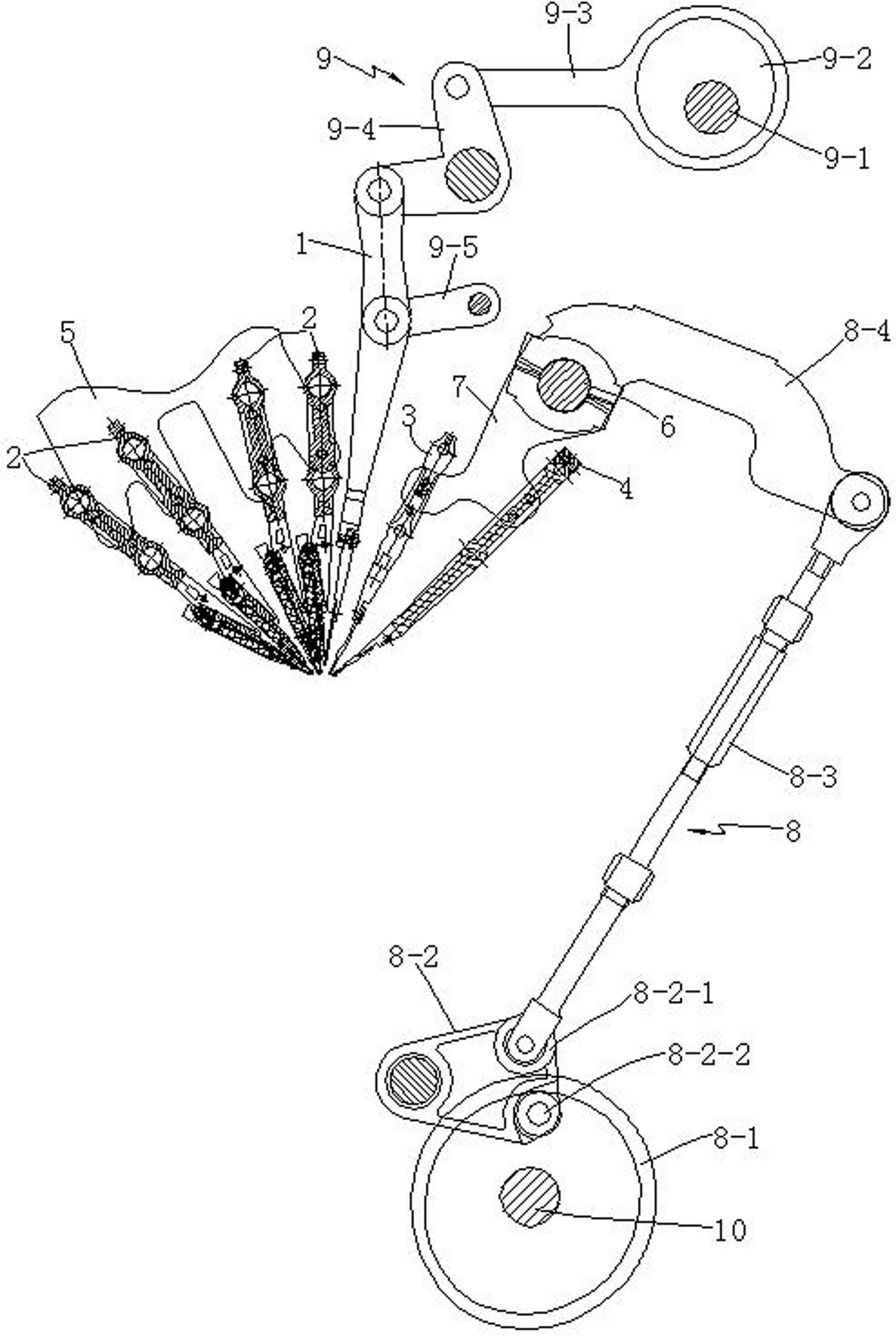

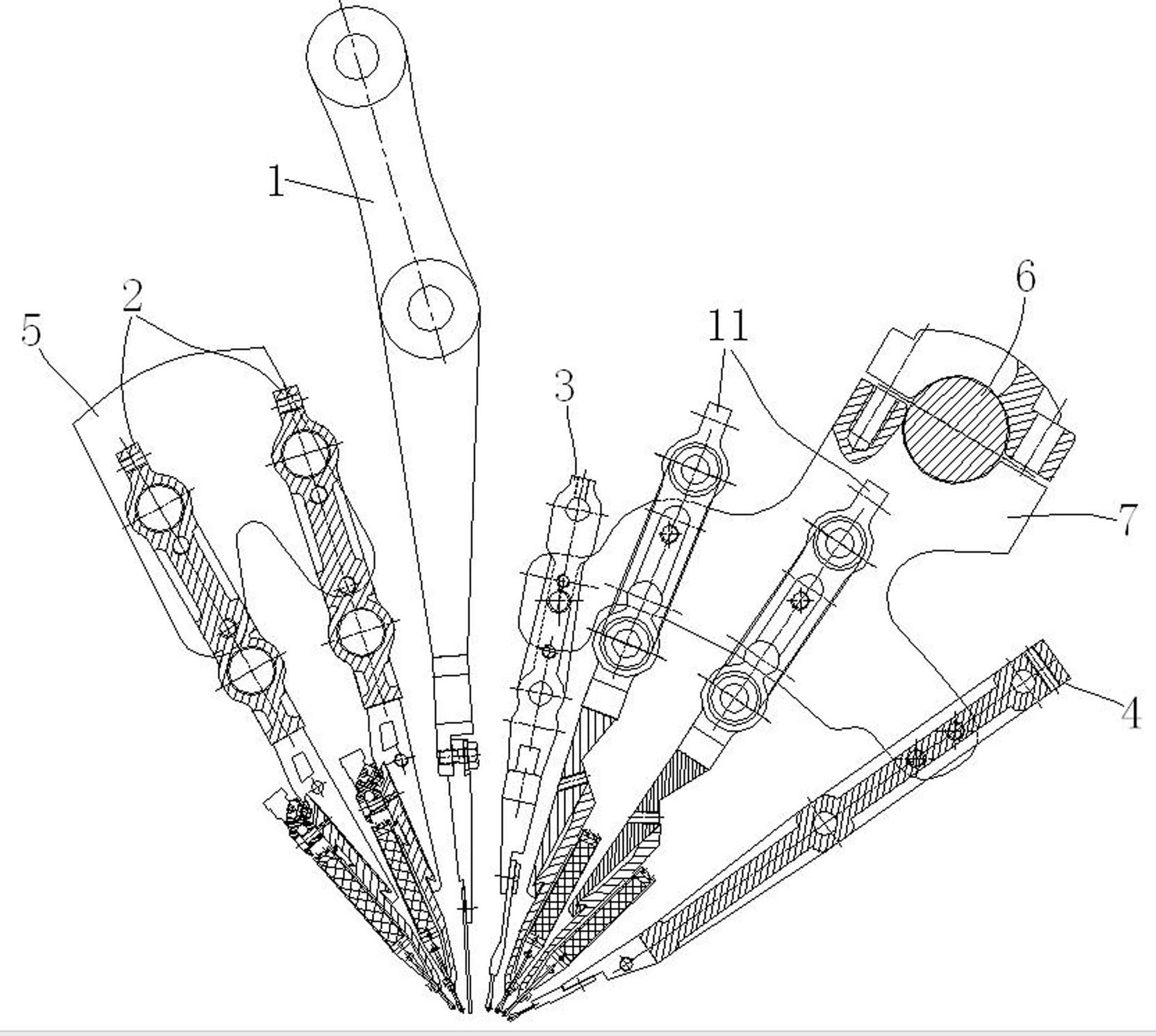

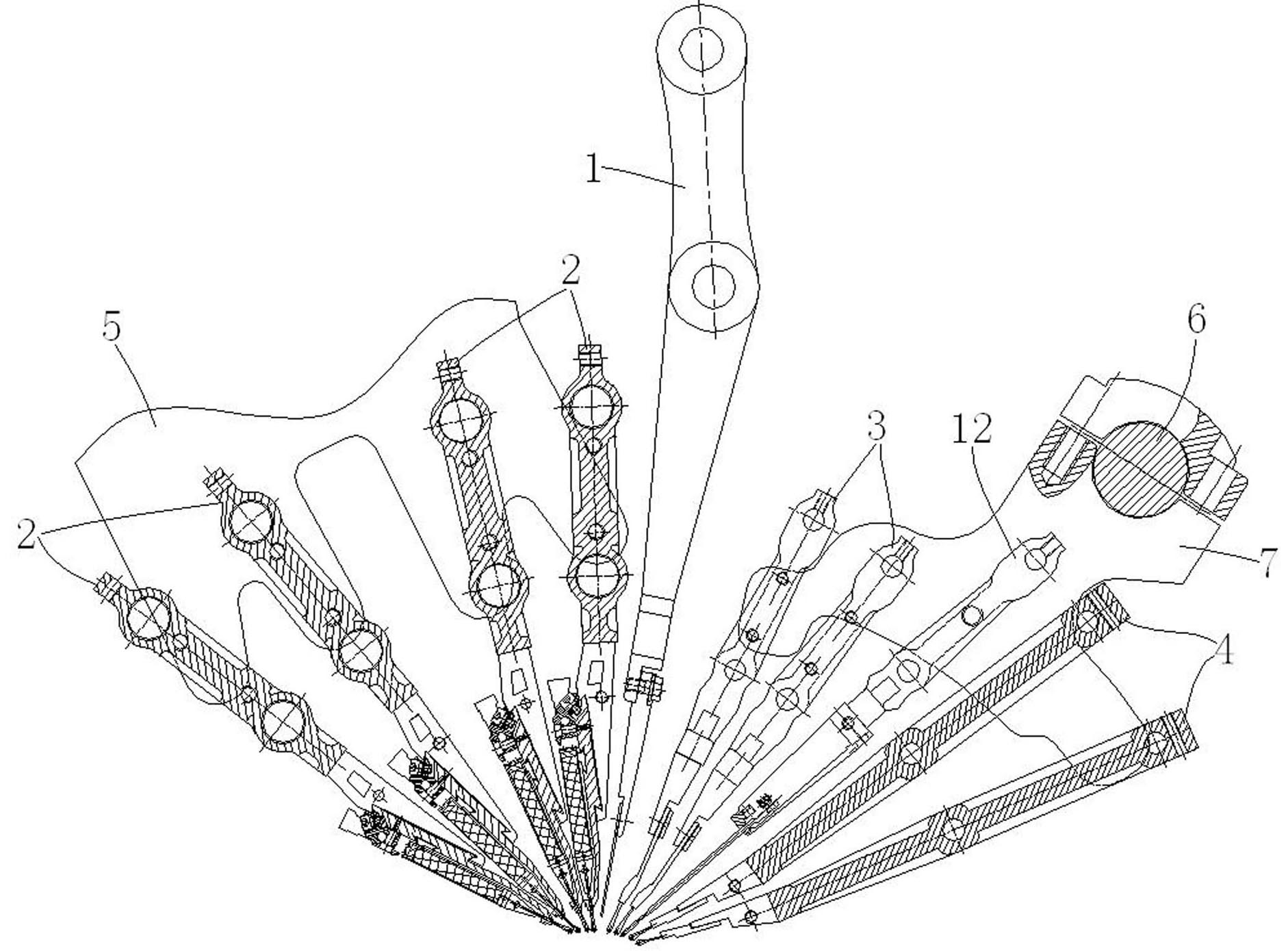

[0013] see Figure 1 to Figure 3 A bar device shown for a yarn pressing type warp knitting machine includes a yarn pressing plate 1, a yarn pressing bar 2, at least one ground bar 3 and at least one spandex bar 4; The bar 2 is installed on the first bar seat 5 fixedly connected with the frame of the warp knitting machine, and the bar device also includes a swing shaft 6 and a second bar seat 7 fixedly connected with the swing shaft 6. A bar seat 5 and a second bar seat 7 are arranged on the front and rear sides of the yarn pressing plate 1 respectively, and the ground bar 3 and the spandex bar 4 are installed on the second bar seat 7 , the swing shaft 6 is driven to swing by the swing transmission mechanism 8, the yarn pressing plate 1 is driven to move by the planar linkage mechanism 9, and the yarn pressing bar 2 is one to two separated full machine gauge yarn pressing jacquard combs comb. Such as figure 1 , 3 As shown, the yarn pressing bars 2 installed on the first bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com