Mold for vehicle support part

A technology of molds and parts, which is applied in the field of molds for automobile support parts, can solve the problems that automobile support parts cannot be produced and processed, and does not have drawing and punching separation, so as to save machine tools and personnel, reduce production costs and maintenance costs , to ensure the effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

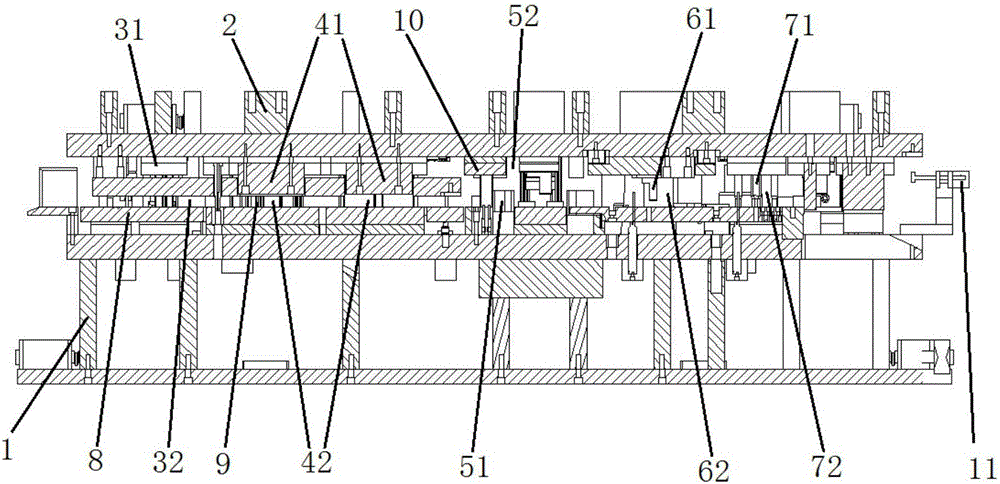

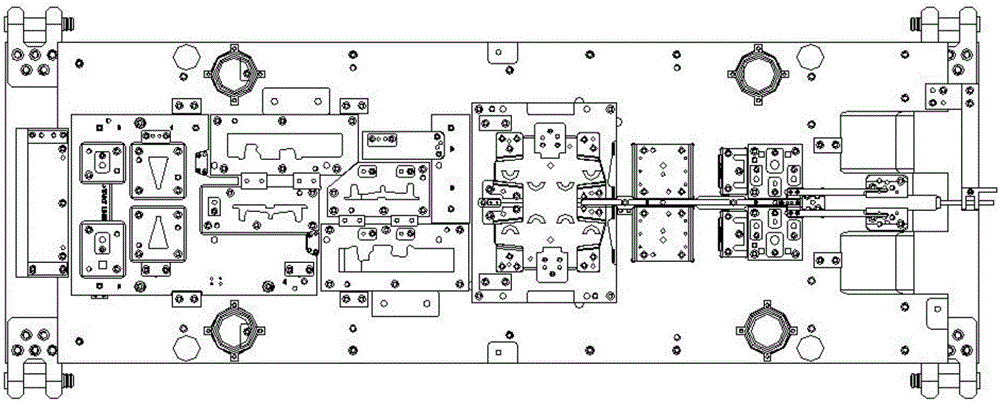

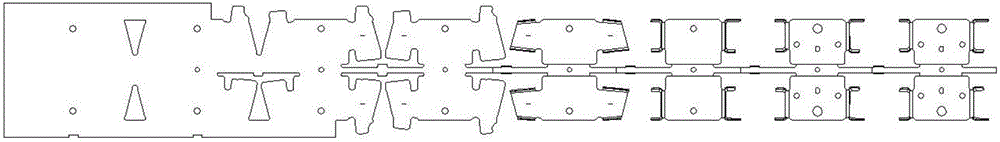

[0031] Such as Figure 1-2 A mold for supporting parts of automobiles is shown, the mold includes a lower mold base 1 and an upper mold base 2, between the lower mold base 1 and the upper mold base 2 are sequentially provided with a drawing unit, a cutting unit, The edge punching unit, the flanging shaping unit and the punching separation unit, the flanging shaping unit includes a first flanging shaping mechanism and a second flanging shaping mechanism arranged in sequence along the moving direction of the strip. The drawing unit includes a drawing punch 31 arranged on the lower surface of the upper die base 2 and a drawing die 32 arranged on the upper surface of the lower die base 1 and adapted to the drawing punch 31; Two step-by-step trimming and punching mechanisms arranged in the moving direction of the strip, the step-by-step trimming and punching mechanism includes a trimming and punching punch 41 arranged on the lower surface of the upper die holder 2 and a punch 41 ar...

Embodiment 2

[0036] In this embodiment, there is one step-by-step trimming and punching mechanism, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com