Continuous production die for rear portion blanking plate parts of automobile carling

A technology for automobile longitudinal beams and parts, which is applied in the field of continuous production of molds, can solve the problems of increasing stamping costs, existing safety, hidden dangers, etc., and achieves the effects of long service life, convenient maintenance and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

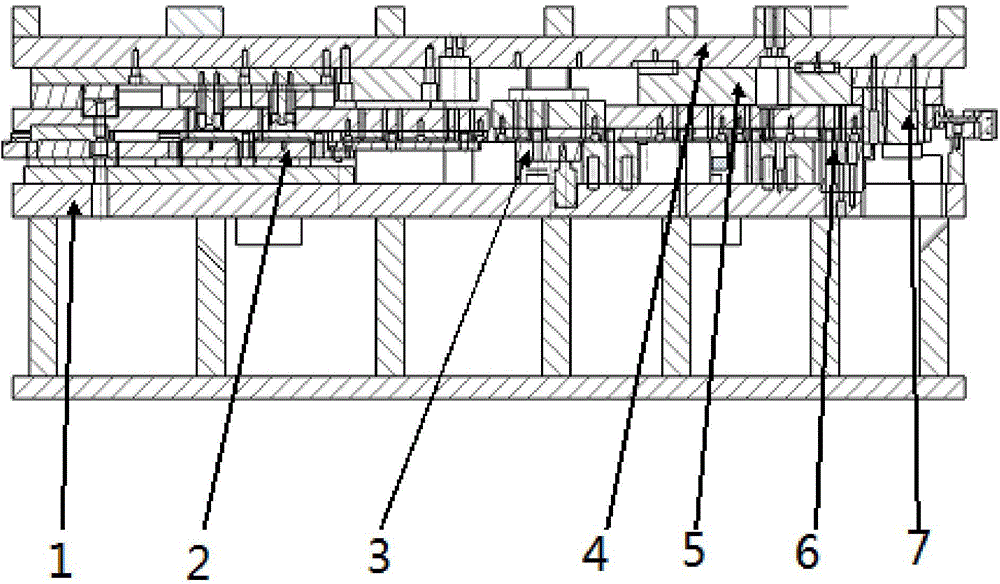

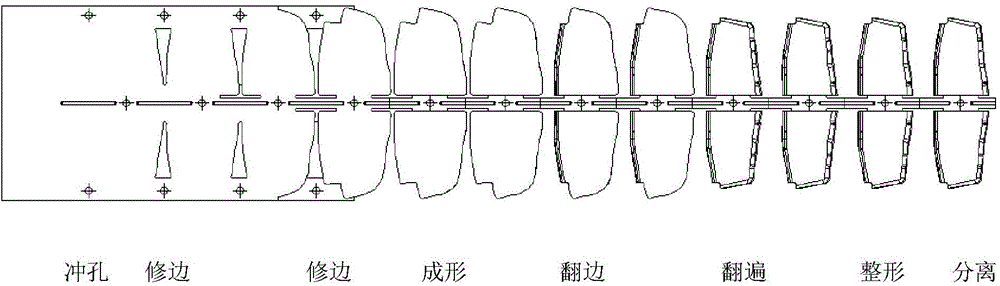

[0025] Such as figure 1 As shown, a continuous production mold for the rear sealing plate parts of the longitudinal beam of the automobile, including

[0026] Lower mold part: including the lower mold base 1, and the stamping die knife 2, the lower mold trimming knife block 3, the flanging lower punch 8, the shaping block, and the discharge port arranged in sequence on the lower mold base 1;

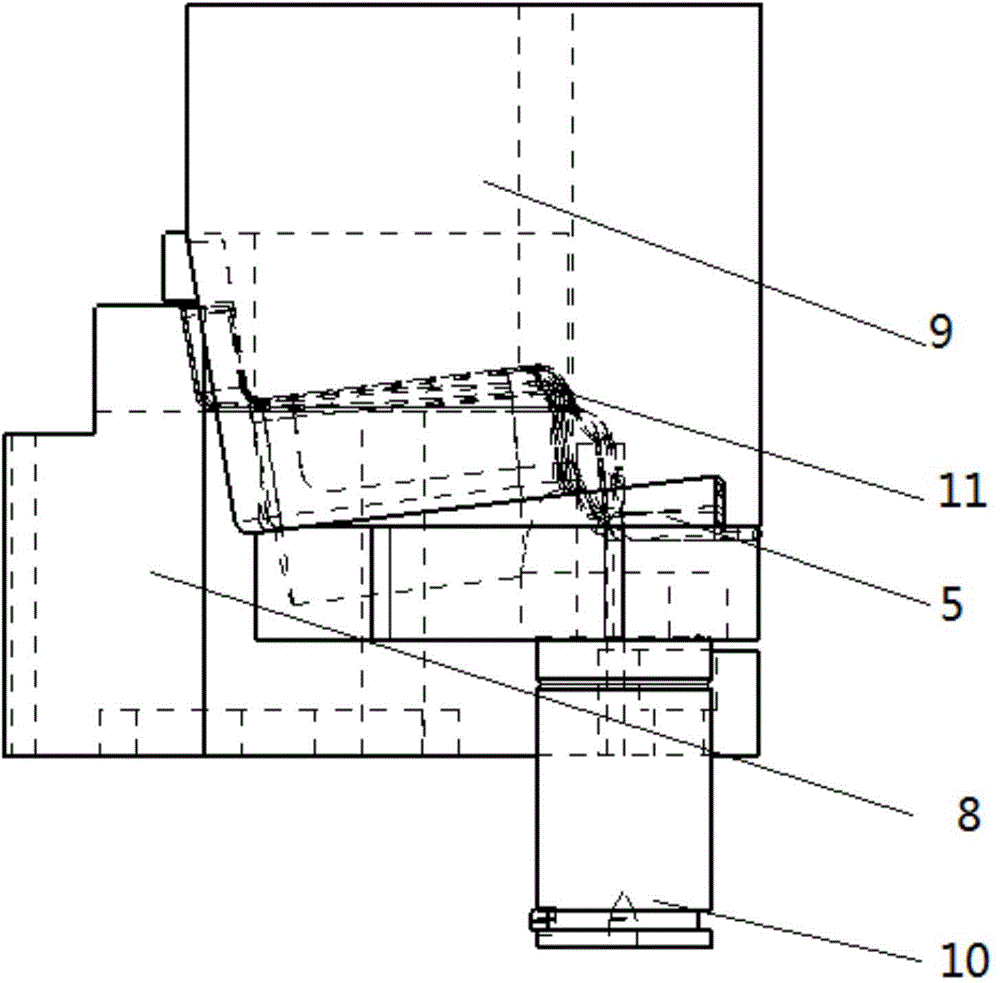

[0027] Upper mold part: including the upper mold base 4, and the stamping punch knife, the upper mold trimming knife block, the flanging knife 9, the binder plate 5, and the shaping punch 6 arranged sequentially on the lower surface of the upper mold base 4; The binder plate 5 is arranged on the middle and lower part of the trimming knife block of the upper mold and is connected with the trimming knife block of the upper mold; Four guide posts.

[0028] The lower flanging punch 8 is provided with a bump that matches the part to be processed, and the binder plate 5 is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com