Sector and rack type reciprocating pump

A reciprocating pump and rack-type technology, which is applied in the direction of pumps, piston pumps, liquid displacement machines, etc., can solve the problems of not being suitable for high-power reciprocating pumps, damage to semicircular gear teeth, and low load-carrying capacity. The space is small, the impact is too large, and the structure is simple and compact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

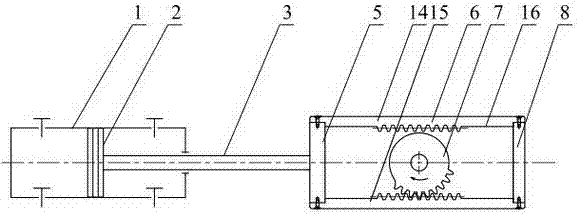

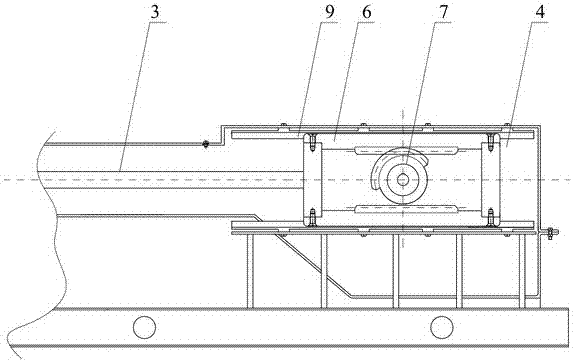

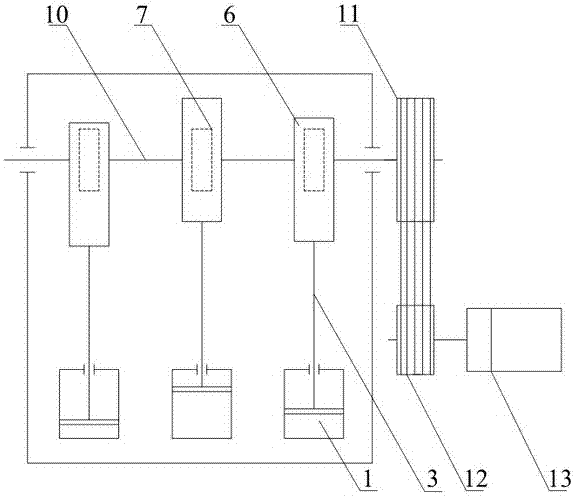

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] See attached Figure 1~6 , the rack-and-segment reciprocating pump of the present invention is mainly composed of a frame (4), an input shaft (10), a rack (7), a rack assembly (6), a guide rail (9), a piston rod (3), a piston (2) and double-acting hydraulic cylinder (1). Among them, the input shaft (10) is fixedly installed on the frame (4) through the bearing, and the input shaft is connected with the motor (13) through the belt drive (11, 12), and the gear fan is installed on the input shaft in the frame cavity. (7), the gear sector (7) meshes with the rack assembly (6), the rack assembly (6) is placed between the upper and lower guide rails (9), and the upper and lower guide rails are fixed on the frame by bolts.

[0024] The toothed sector (7) meshes with the rack assembly (6). During the rotation of the toothed sector, when the toothed sector (7) meshes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com