Exposure method and exposure machine

An exposure method and exposure machine technology, which are applied in the direction of photomechanical equipment, microlithography exposure equipment, and photolithography exposure equipment, etc., can solve the problems of low exposure accuracy, limited exposure accuracy, and large graphic size, and achieve high precision Structure, the effect of high exposure precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An exposure method provided by an embodiment of the present invention. In this embodiment, the exposure method is used to manufacture the color filter layer on the color filter substrate.

[0035] The exposure methods include:

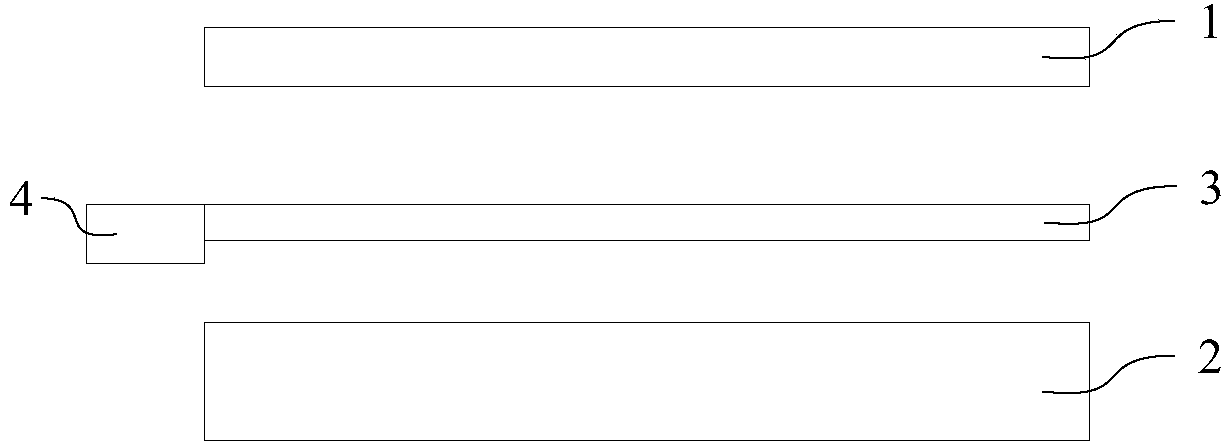

[0036] S1: placing the mask plate at a first position above the substrate to be exposed.

[0037] Wherein, the substrate is coated with a photoresist (ie, a color filter layer), and in this embodiment, a negative photoresist that is relatively common in the manufacture of a color filter layer is used.

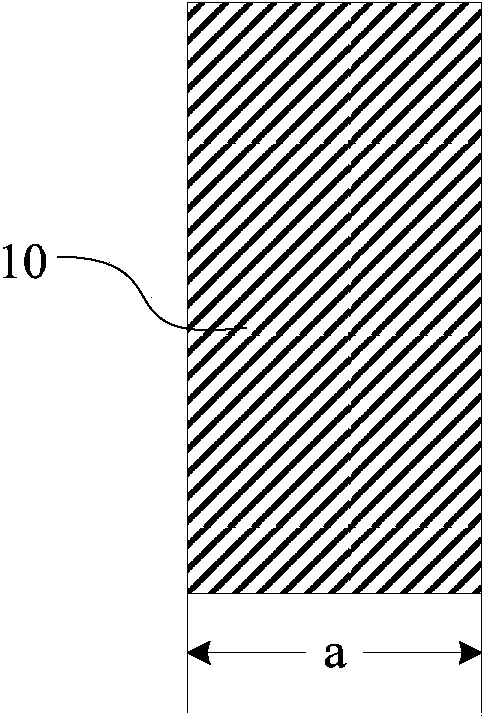

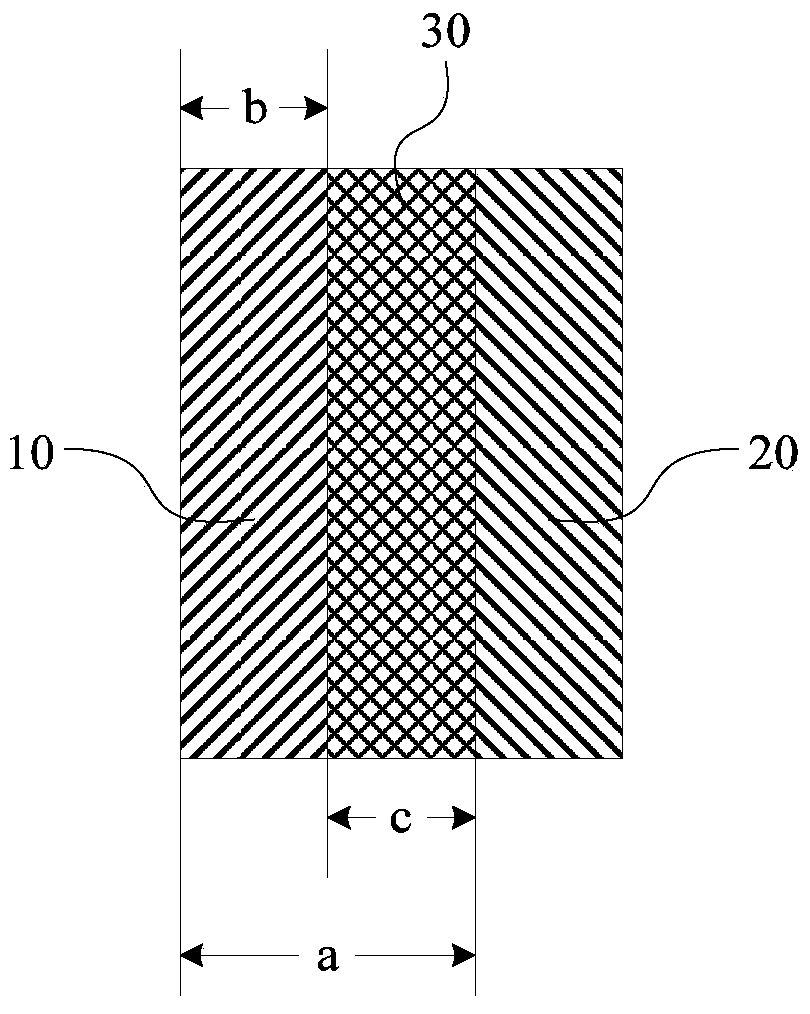

[0038] S2: if figure 1 As shown, a first region 10 of photoresist on the substrate is exposed.

[0039] In this embodiment, the precision dimension of the exposure machine is 8 μm, that is, the minimum dimension a in the first region to be exposed is 8 μm.

[0040] In addition, the conventional exposure dose for negative photoresist is generally 50mJ, but the exposure dose in this step should be less than the conventional exposure dose, and t...

Embodiment 2

[0061] The exposure method provided by this embodiment is basically the same as that of Embodiment 1, the difference is that in step S3, the moving direction of the mask plate is oblique translation.

[0062] Such as Figure 4 As shown, after the mask plate is translated obliquely, there is not only a lateral displacement difference b but also a certain longitudinal displacement difference d between the first region 10 and the second region 20 . After the second exposure and development, the pattern formed by the photoresist can not only achieve higher exposure accuracy in the horizontal dimension, but also achieve higher exposure accuracy in the vertical dimension, so that it can be in both the horizontal and vertical directions. It can meet the demand of high-precision structure of liquid crystal display.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com