Exposure apparatus

An exposure device and an exposed technology, which are applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of natural vibration frequency reduction, inability to solve flatness, and adverse effects of exposure accuracy, etc., to improve exposure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

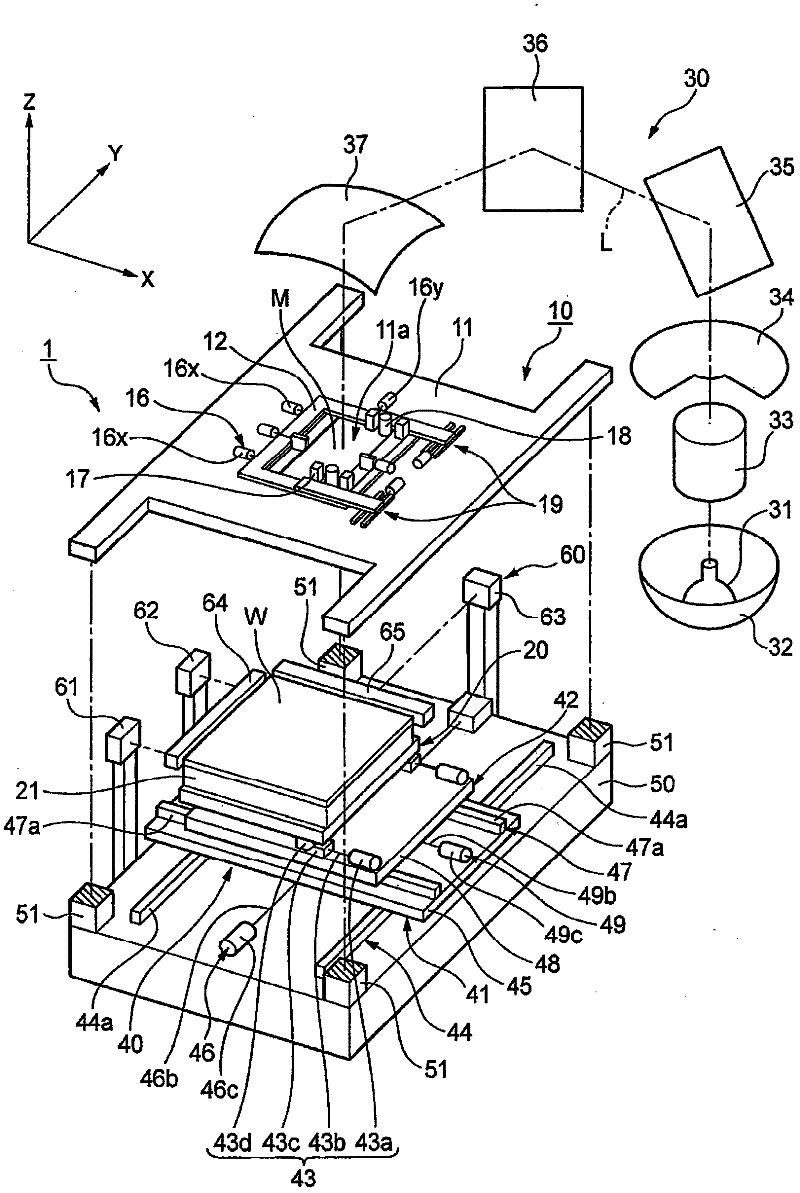

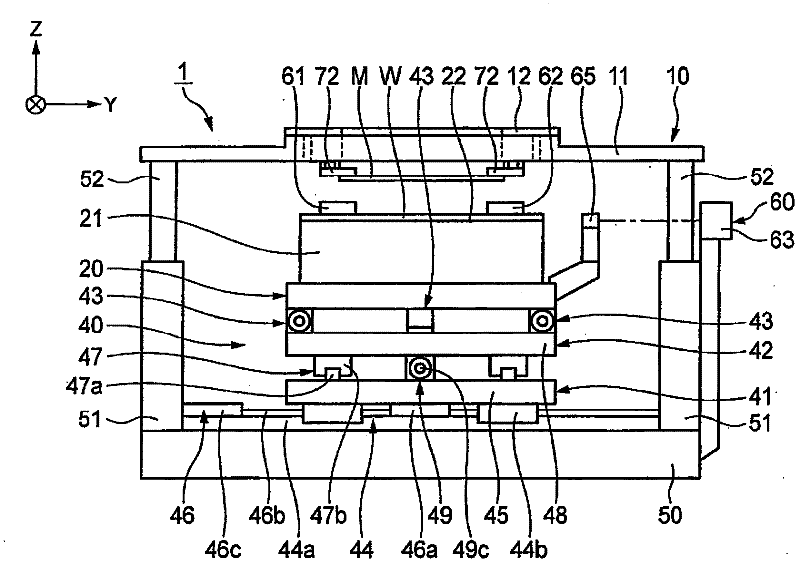

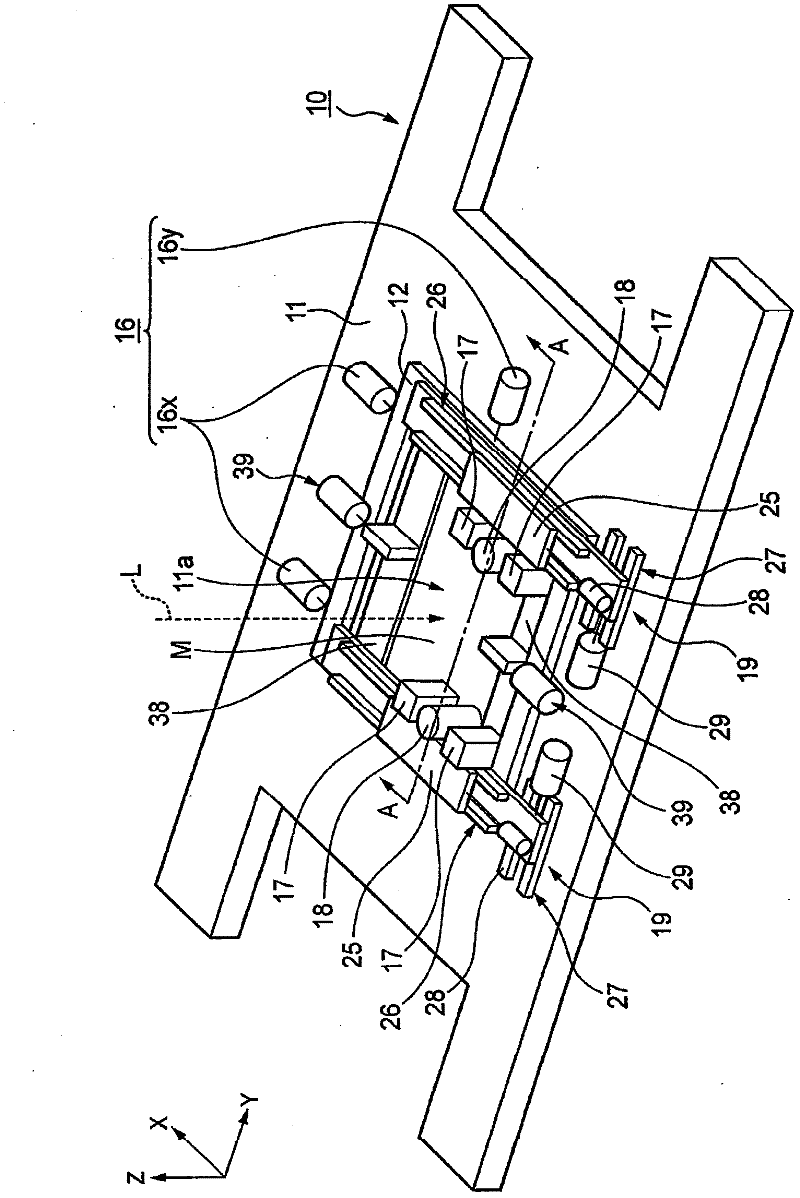

[0110] figure 1 It is a perspective view of main parts of an exposure apparatus as a first embodiment of the present invention, figure 2 is the main view, image 3 is an enlarged view of the portion near the mask table, Figure 4 is a top view of the mask table.

[0111] Such as figure 1 As shown, the exposure apparatus 1 of this embodiment has: a mask stage 10 for holding a mask M; a substrate stage 20 for holding a glass substrate (material to be exposed) W; and an illumination optical system as an irradiation mechanism for pattern exposure. 30. The substrate stage moving mechanism 40, which moves the substrate stage 20 in the X-axis, Y-axis, and Z-axis directions, and adjusts the inclination of the substrate stage 20; and a device for supporting the mask stage 10 and the substrate stage moving mechanism 40 Base 50.

[0112] In addition, the glass substrate W (hereinafter simply referred to as "substrate W") is disposed opposite to the mask M, and the mask pattern dr...

no. 2 approach

[0162] Figure 12 It is a figure which shows the exposure apparatus of 2nd Embodiment which differs from 1st Embodiment in a tilt angle adjustment mechanism. In the exposure apparatus 1 of this embodiment, the inclination angle adjustment mechanism 80 is arrange|positioned between the mask holding frame 12 and the guide rail 73a.

[0163] According to such exposure apparatus 1, similarly to 1st Embodiment, it is not necessary to exchange|exchange a mask holder, and it is possible to suction-hold a some mask of a different size accordingly. In addition, regardless of the size of the mask M, the inclination angle can be adjusted by the inclination angle adjustment mechanism 80, and the flatness of the mounted mask M can be corrected, and the gap between the mask M and the substrate W can be maintained at Be sure to increase exposure accuracy. In addition, in the case of the present embodiment, the height of the suction position of the movable mask holder 72 on the short side a...

no. 3 approach

[0167] Figure 14 In the exposure apparatus of the third embodiment, when the movable mask holder is tilted by the inclination angle adjusting mechanism, a mechanism for adjusting the level difference generated between the fixed mask holder and the movable mask holder is shown.

[0168] For example, if Figure 15 As shown, when adjusting the inclination angle of the movable mask holder 72, sometimes there is a height difference (step difference) between the fixed mask holder 71 and the movable mask holder 72. If the step difference is large, the rigidity of the brackets 71 and 72 is high. , therefore, a gap C is generated between the movable mask holder 72 and the mask M, which may adversely affect exposure accuracy.

[0169] Therefore, if Figure 14 As shown, in the fixed mask holder 71 and the movable mask holder 72, the upper surfaces of side edge portions 71d, 72d close to each other are notched to form thinner portions 71e, 72e than the rest. When the thin-walled porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com