Off-line cleaning method for reverse osmosis membranes

A reverse osmosis membrane, off-line technology, applied in the field of reverse osmosis cleaning, can solve the problems of membrane damage and poor cleaning effect, and achieve the effect of ensuring the desalination rate, ensuring the water flux and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

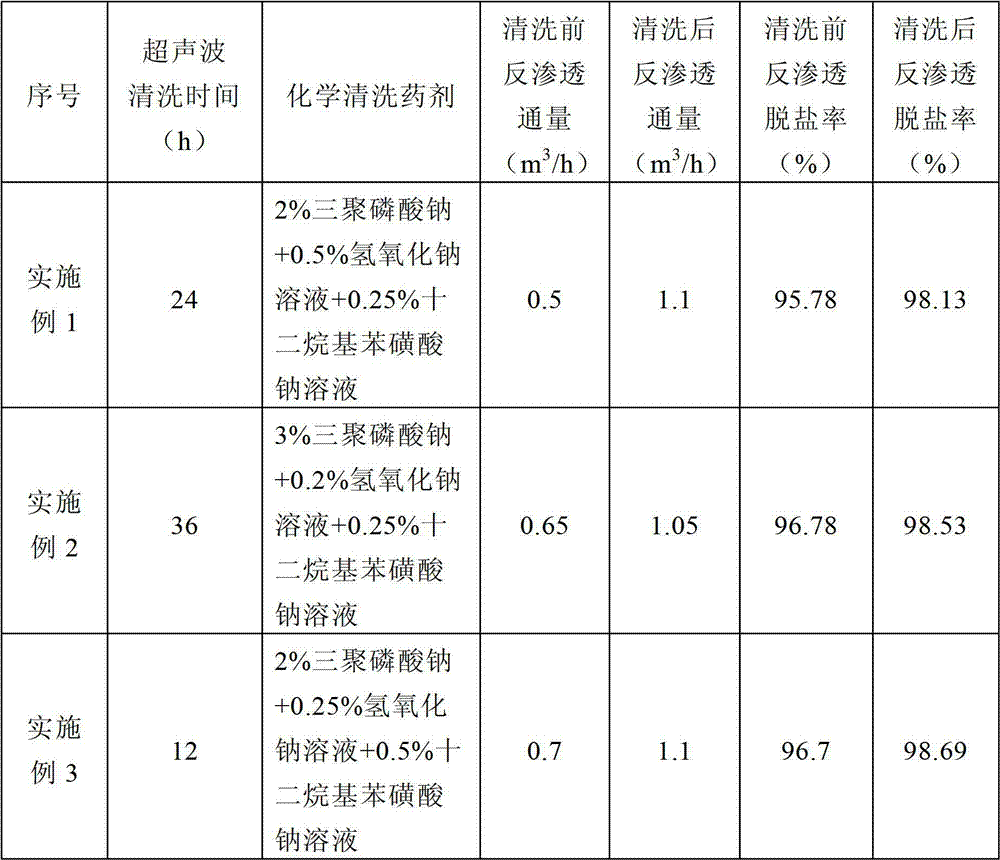

Embodiment 1

[0036] Preparation of cleaning solution: Use pure water to prepare cleaning solution: 2% sodium tripolyphosphate + 0.5% sodium hydroxide solution + 0.25% sodium dodecylbenzenesulfonate solution, put it into the cleaning solution storage tank 3, and adjust to the required temperature : 25°C.

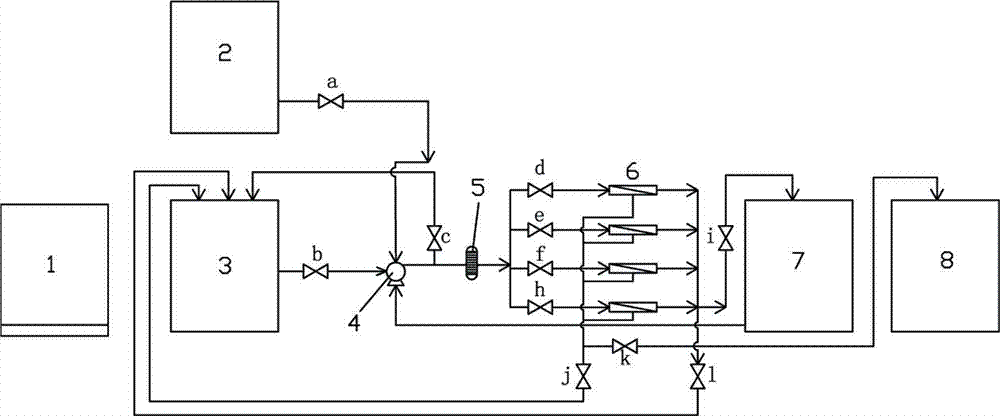

[0037] see figure 1 , put the reverse osmosis membrane into the ultrasonic cleaning tank 1, and put in the cleaning agent, adjust the ultrasonic frequency to 60KHz, and perform ultrasonic cleaning, and the cleaning time is 24h;

[0038] The reverse osmosis membrane after the ultrasonic cleaning is packed in the reverse osmosis membrane tube 6, the cleaning chemical agent A is loaded into the cleaning liquid storage tank 3, the outlet valve b of the cleaning liquid storage tank 3 is opened, and the The valves d, e, f, h of the pipeline 6, and the valves j, l connected to the outlet pipeline of the reverse osmosis membrane tube 6, open the frequency conversion water supply pump 4, keep the...

Embodiment 2

[0046] Preparation of cleaning solution: Use pure water to prepare cleaning solution: 3% sodium tripolyphosphate + 0.2% sodium hydroxide solution + 0.25% sodium dodecylbenzenesulfonate solution, put it into the cleaning solution storage tank 3, and adjust to the required temperature : 25°C.

[0047] Put the reverse osmosis membrane into the ultrasonic cleaning tank 1, and put in the cleaning agent to adjust the ultrasonic frequency to 70KHz, and perform ultrasonic cleaning for 36 hours.

[0048]Put the reverse osmosis membrane after ultrasonic cleaning into the reverse osmosis membrane tube 6, fill the cleaning liquid storage tank 3 with cleaning chemicals, open the valves b, d, e, f, h, j, l, and turn on the frequency conversion water supply pump 4. Keep the pressure within 0.5MPa, if the pressure is too high, open the valve c to adjust the pressure.

[0049] The first low-flow cycle: the total cycle cleaning time is 20 minutes, and the flow rate of the pressure vessel of ea...

Embodiment 3

[0056] Preparation of cleaning solution: Use pure water to prepare cleaning solution: 2% sodium tripolyphosphate + 0.25% sodium hydroxide solution + 0.5% sodium dodecylbenzenesulfonate solution, put it into the cleaning solution storage tank 3, and adjust to the required temperature : 25°C.

[0057] Put the reverse osmosis membrane into the ultrasonic cleaning tank 1, and put in the cleaning agent to adjust the ultrasonic frequency to 50KHz, and perform ultrasonic cleaning for 12 hours.

[0058] Put the reverse osmosis membrane after ultrasonic cleaning into the reverse osmosis membrane tube 6, fill the cleaning liquid storage tank 3 with cleaning chemicals, open the valves b, d, e, f, h, j, l, and turn on the frequency conversion water supply pump 4. Keep the pressure within 0.5MPa, if the pressure is too high, open the valve c to adjust the pressure.

[0059] The first low-flow cycle: the total cycle cleaning time is 20 minutes, and the flow rate of the pressure vessel of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com