Patents

Literature

41results about How to "Easy to use and ingenious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

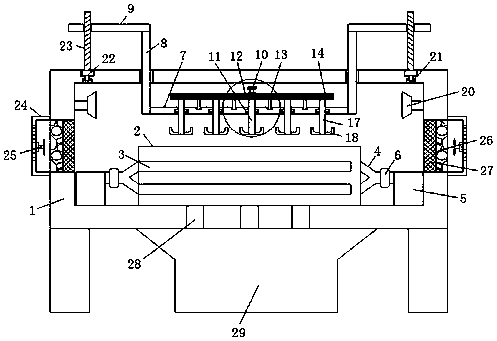

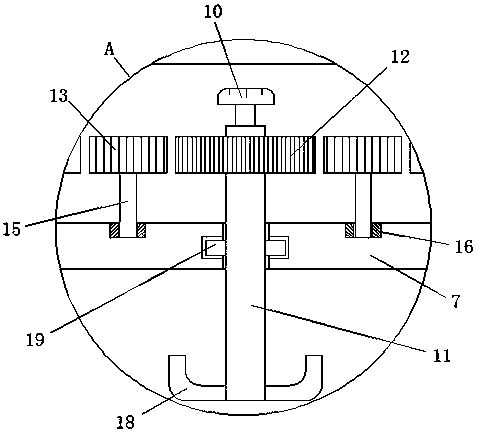

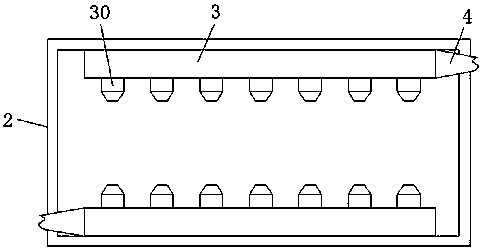

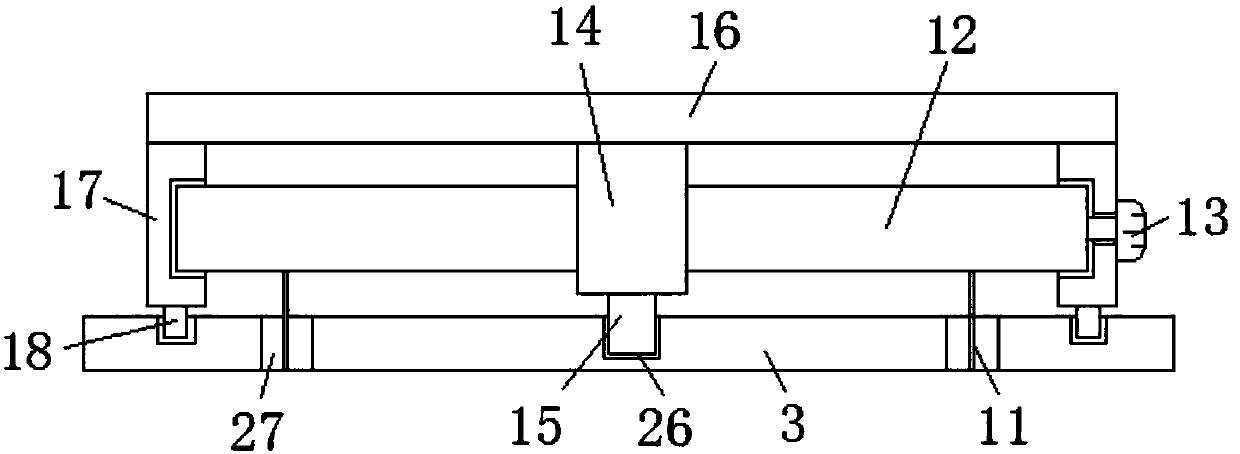

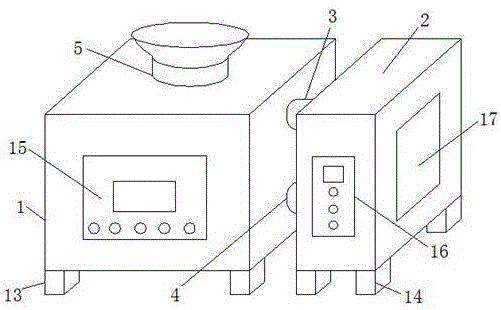

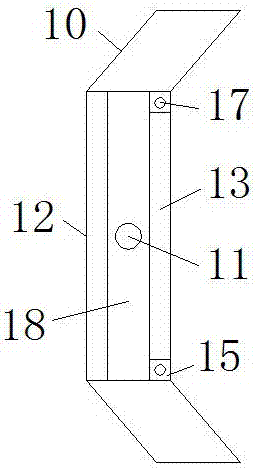

Hardware fitting machining perforating device with automatic dust removal function

InactiveCN107695780AKeep Countertops CleanGood countertop cleanlinessMaintainance and safety accessoriesBoring/drilling machinesComputer hardwareDust control

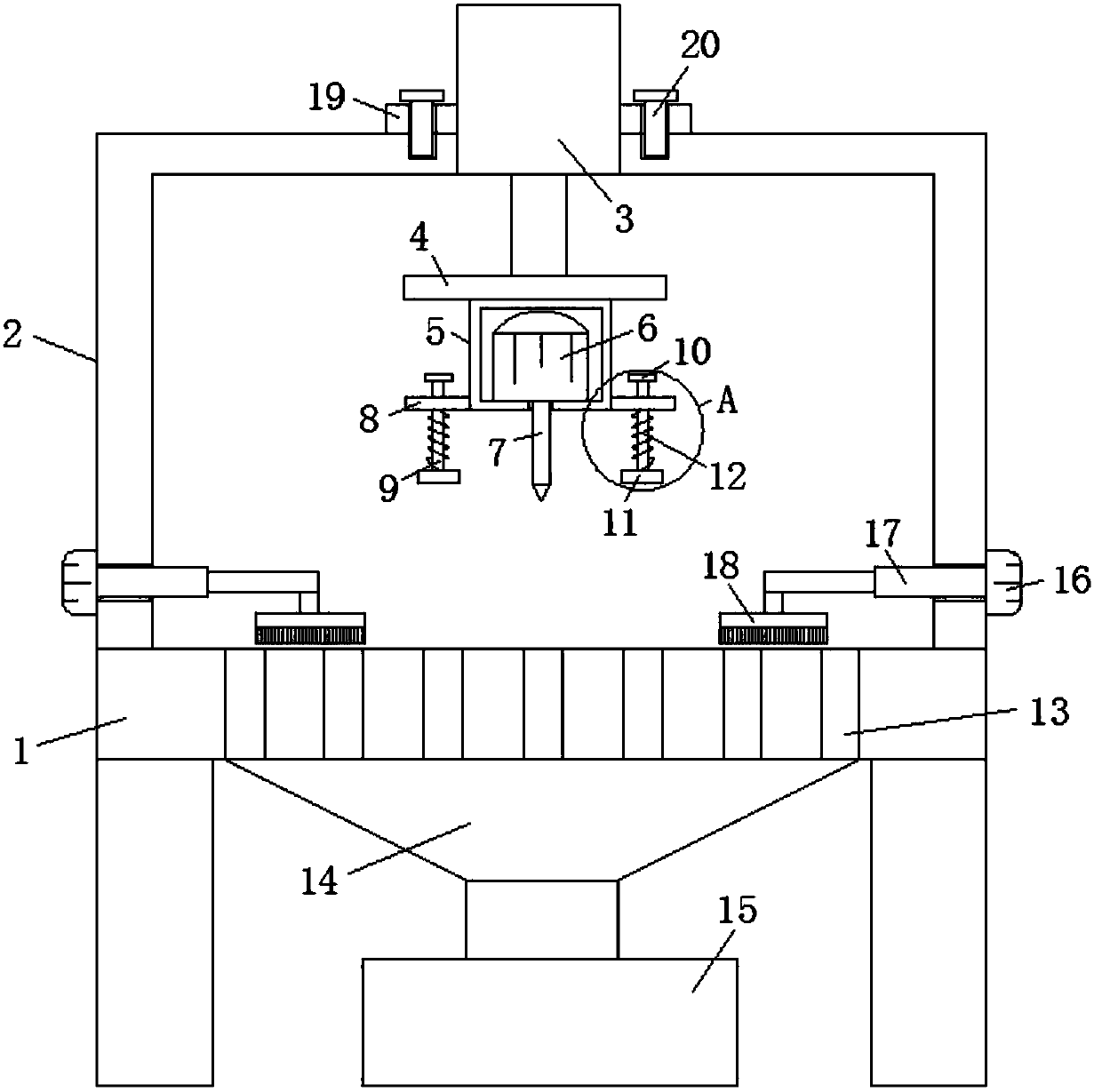

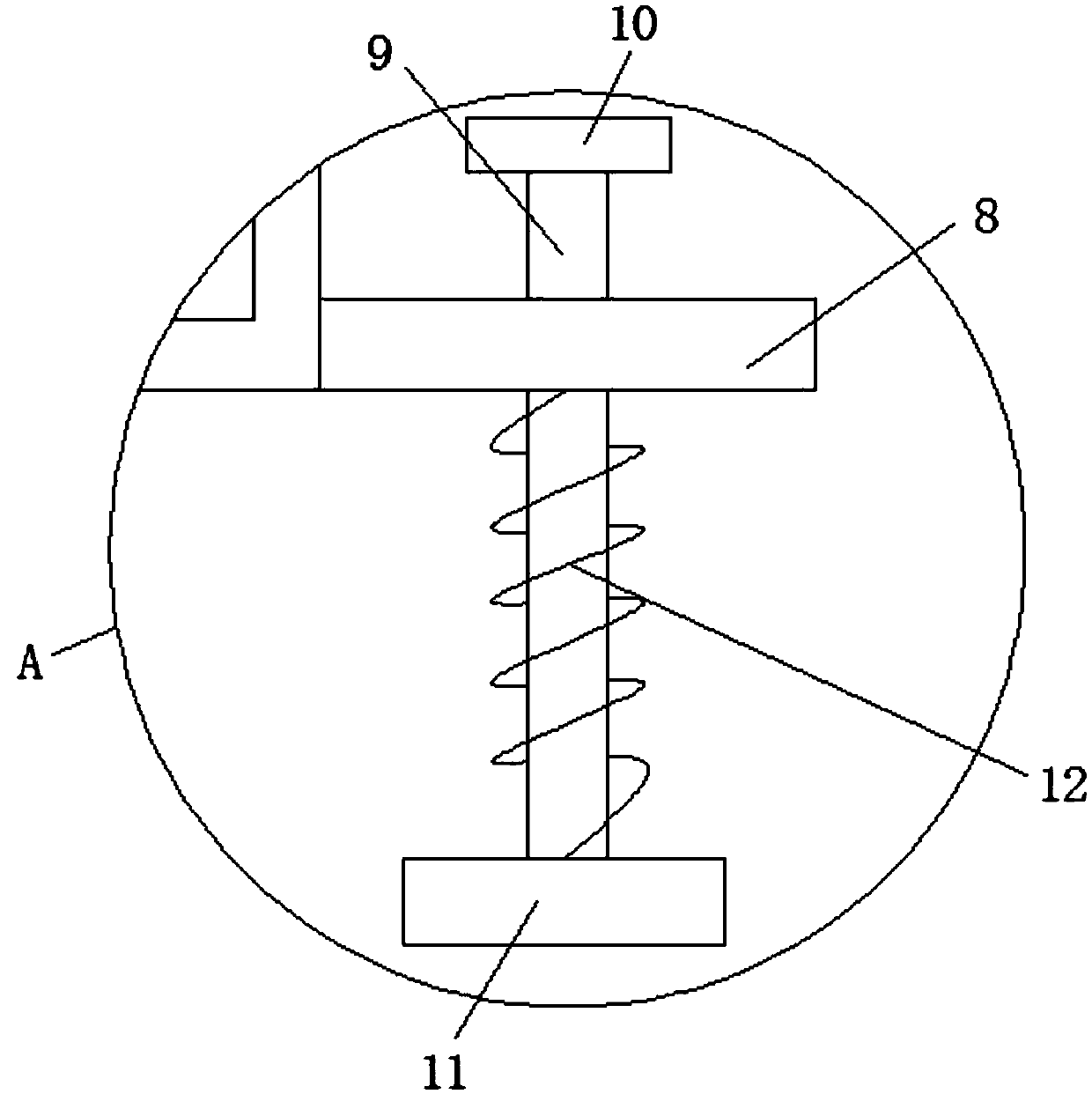

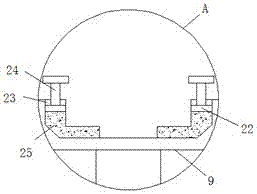

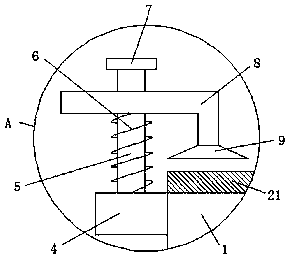

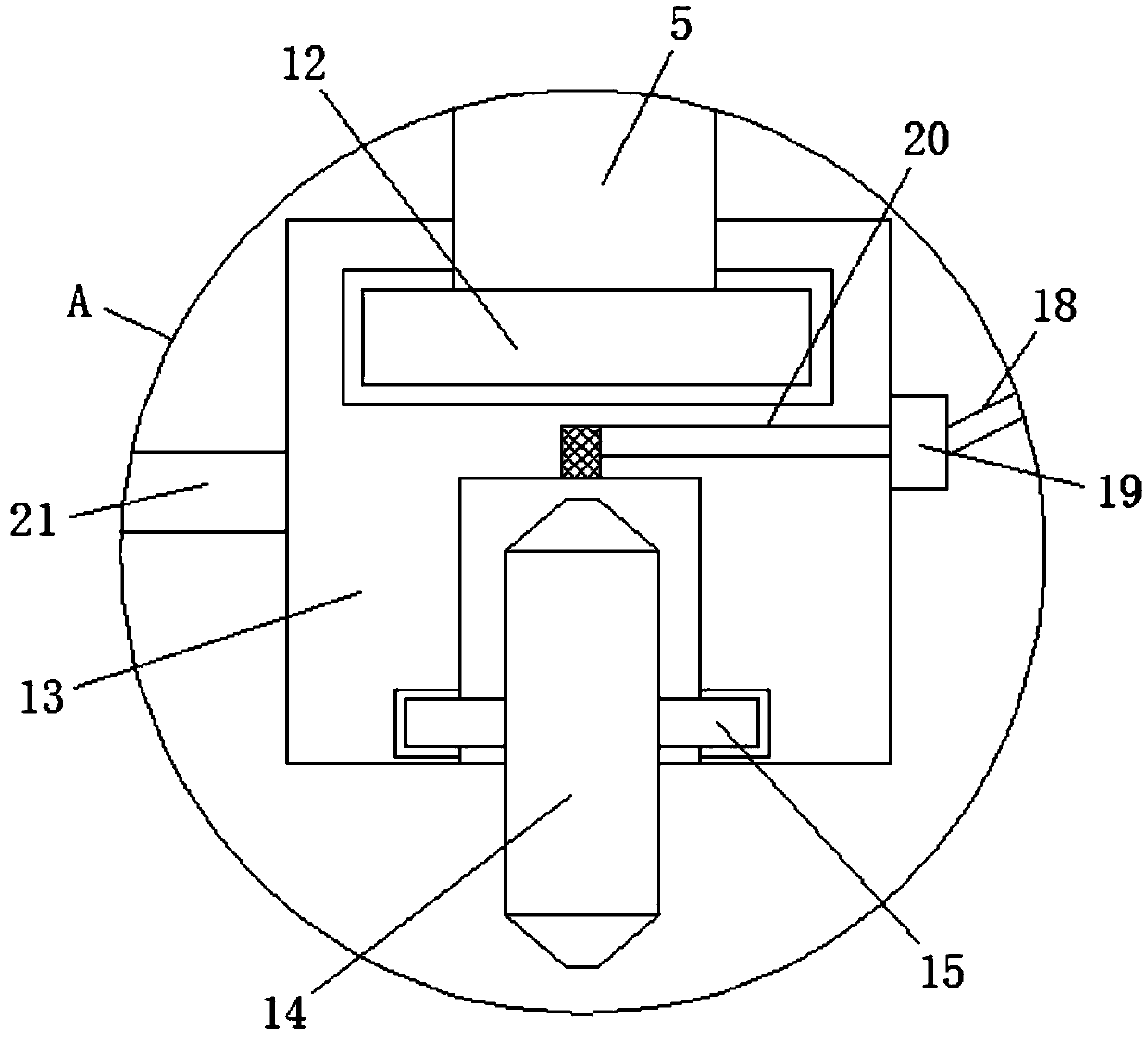

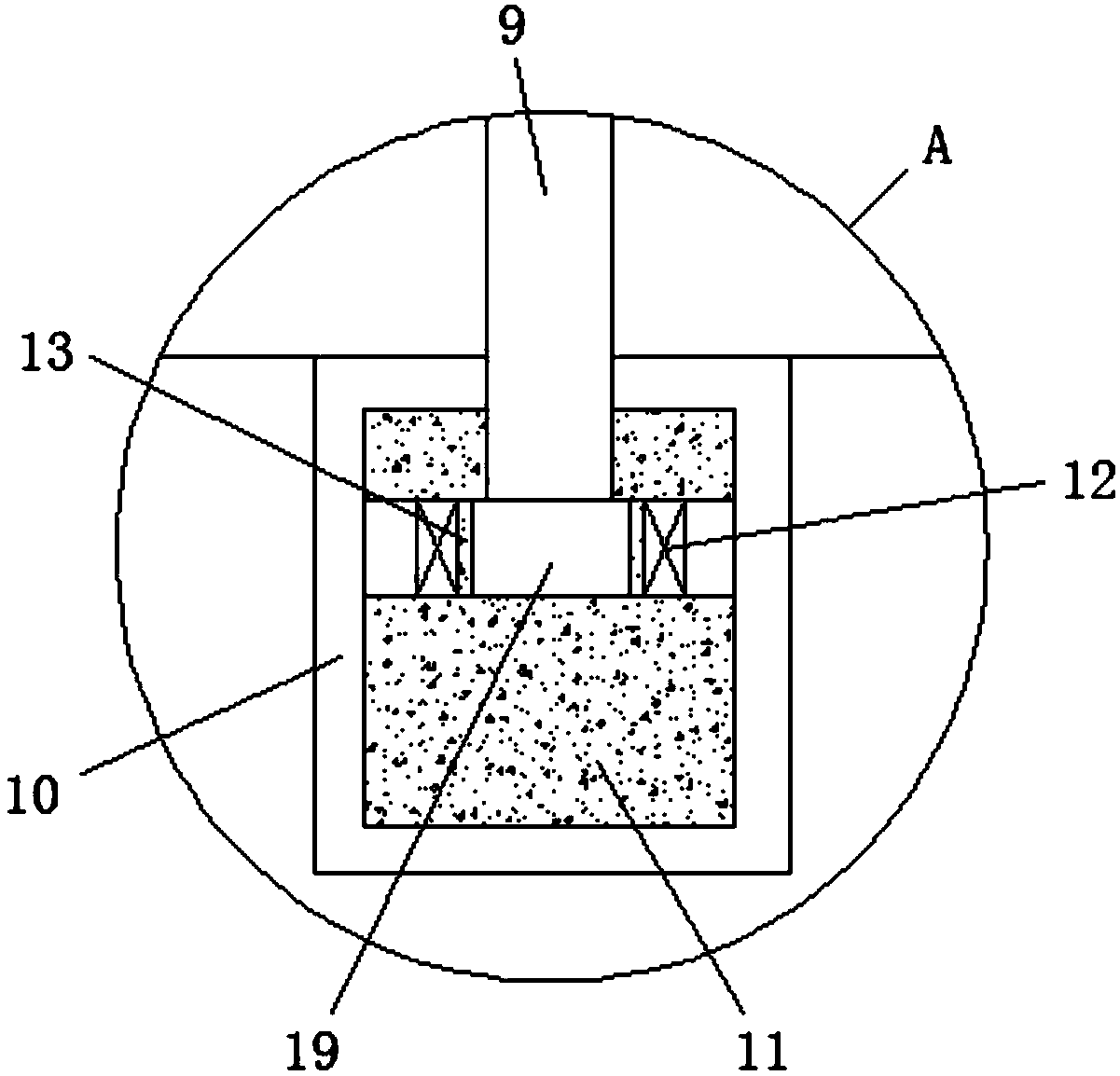

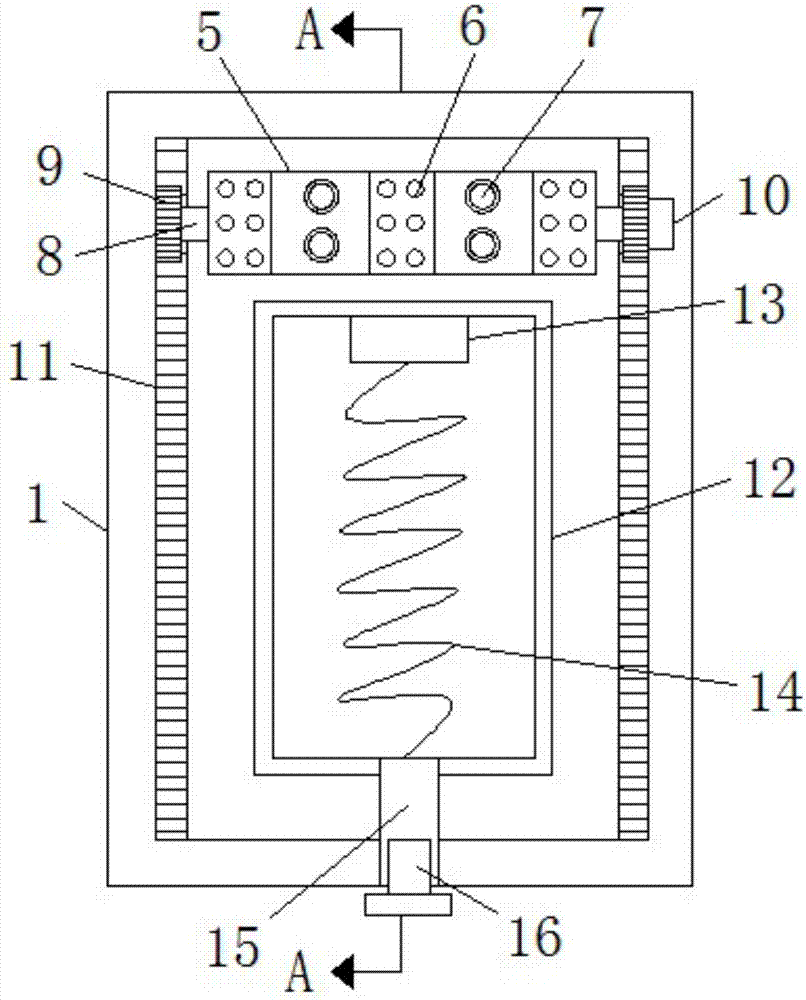

The invention discloses a hardware fitting machining perforating device with an automatic dust removal function. The hardware fitting machining perforating device comprises a working table, a box shell is fixedly connected to the upper end of the working table, an air cylinder is arranged at the center of the upper end of the box shell, a fixing plate is fixedly connected to the lower end of the air cylinder through a piston rod, a motor shell is fixedly connected to the bottom of the fixing plate, a hole drilling motor is installed inside the motor shell, a drill bit is fixedly connected to an output shaft of the hole drilling motor, a plurality of chip spaces are evenly formed in the inner wall of the table face of the working table, a dust cage is communicated with the bottoms of the chip spaces, and the lower end of the dust cage is connected with a dust collector through a guide pipe. The hardware fitting machining perforating device is simple in structure and easy to operate, chippings generated by perforating can be collected, meanwhile, the cleaning effect is better, and the table face cleanliness of the working table is kept.

Owner:泰州亚东链条有限公司

Environmental-friendly multifunctional cutting device for building material

PendingCN107379287AEasy to cutAvoid pollutionWorking accessoriesStone-like material working toolsFixed frameSpray nozzle

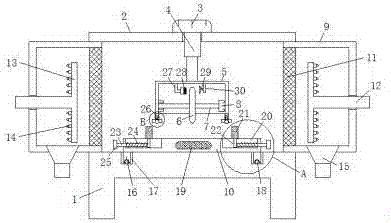

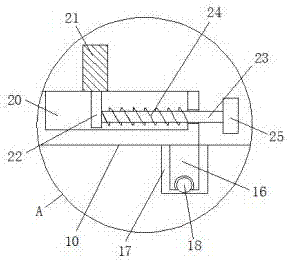

The invention discloses an environmental-friendly multifunctional cutting device for a building material. The environmental-friendly multifunctional cutting device comprises a fixing frame. A machine body shell is fixedly connected to the upper end of the fixing frame. The lower end of a first drive motor is fixedly connected with a mounting shell through a first telescopic rod. A rotary shaft is arranged on one side of a second drive motor. A cutting blade is arranged in the center of the outer wall of the rotary shaft. Shock absorption devices are symmetrically arranged on the two sides of the lower end of the mounting shell. Suction hoods are symmetrically arranged on the two sides of the outer wall of the machine body shell. A water inlet pipe is inserted into one side of the outer wall of each suction hood. The two sides of the end, penetrating the outer wall of the corresponding suction hood and extending inwards, of each water inlet symmetrically communicate with water spray pipes. Multiple spray nozzles are uniformly arranged on one side of the outer wall of each water spray pipe. A bottom plate is arranged at the upper end of the fixing frame. Sliding blocks are symmetrically and fixedly connected to the two sides of the bottom of the bottom plate. The environmental-friendly multifunctional cutting device is simple in structure and easy to operate and has the positioning clamping and dust removal functions, meanwhile the machining quality is improved, and the pollution to the environment is avoided.

Owner:长兴县太湖编织袋有限公司

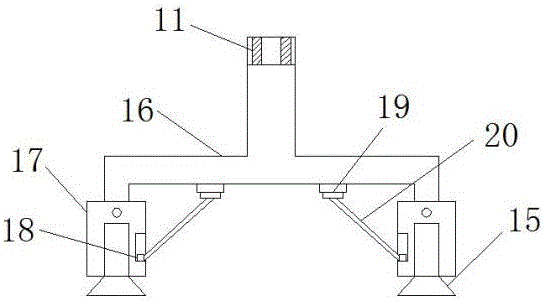

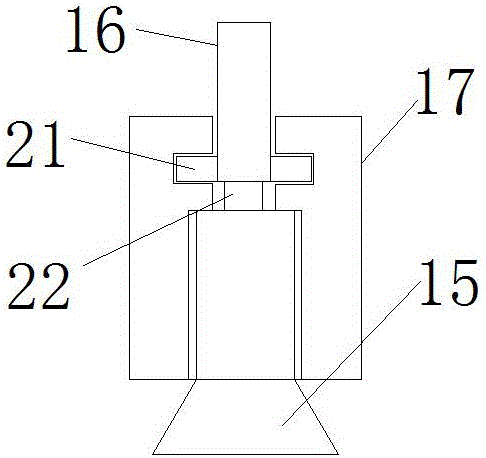

Spraying type industrial robot

InactiveCN107321534AEasy to sprayThe turntable turns smoothlySpraying apparatusPretreated surfacesCouplingEngineering

The invention discloses a spraying type industrial robot. The spraying type industrial robot comprises a base; annular clamping blocks are arranged on the base through annular clamping grooves, a rotary table is fixedly connected to the annular clamping blocks, the center of the bottom of the rotary table is connected with a first driving motor through a first rotary shaft, the first driving motor is fixed in an inner cavity of the base, a fixing frame is fixedly connected to the rotary table, a second driving motor is arranged at the bottom of the fixing frame, the second driving motor is connected with a coupler through a second rotary shaft, a threaded rod is arranged at the end, far away from the second rotary shaft, of the couple, the external of the threaded rod is screwed with a movable part, and connecting rods are symmetrically and fixedly connected to the two sides of the outer wall of the movable part; a mechanical arm is rotationally connected with the end, far away from the movable part, of each connecting rod; a spraying gun is arranged on the end, away from the corresponding connecting rod, of each mechanical arm, the end portion of each spraying gun communicates with a spraying pipeline, each spraying pipeline penetrates through the inner wall of the corresponding mechanical arm and extends outwards to communicate with a spraying box, fixing plates are symmetrically arranged on the two sides of the outer wall at the lower end of the movable part, an inclined block is fixedly connected to each fixing plate, a third driving motor is arranged on the outer side of each inclined block, each third driving motor is rotationally connected with a sliding block through a telescopic rod, and the lower side of the outer wall of each mechanical arm is provided with a sliding groove corresponding to the corresponding sliding block.

Owner:SUZHOU INST OF INDAL TECH

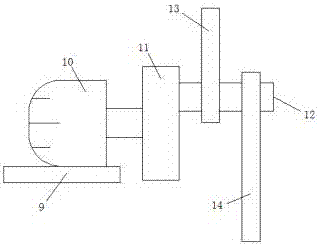

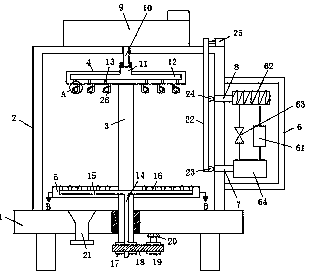

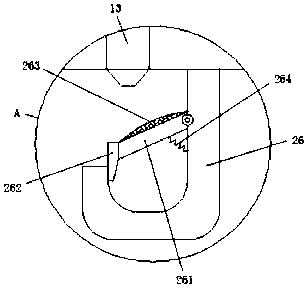

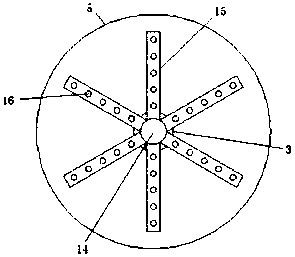

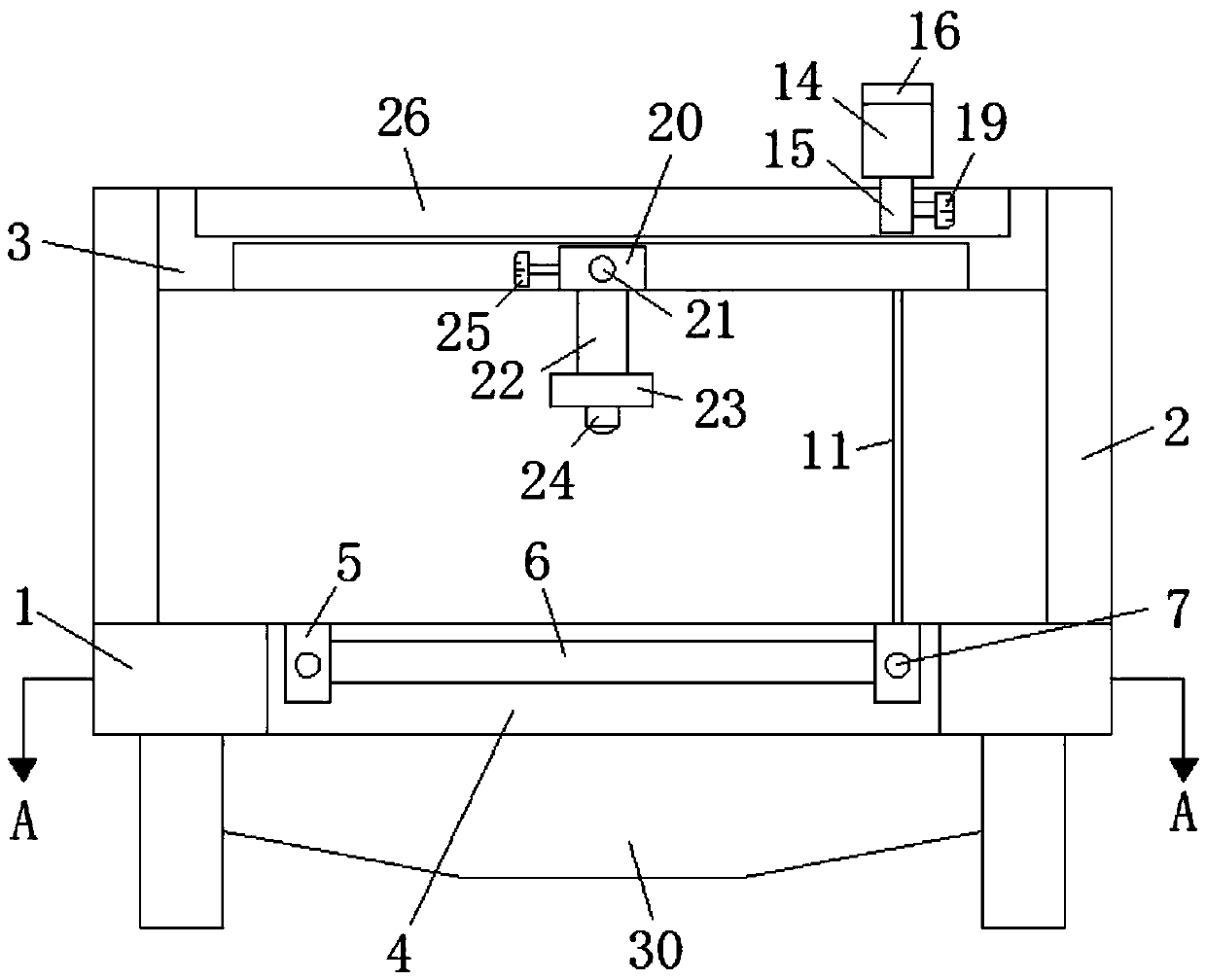

Automobile part paint spraying device with fast drying effect

InactiveCN107670892AGood effectAchieve rotationLiquid spraying apparatusSpray boothsSpray nozzleEngineering

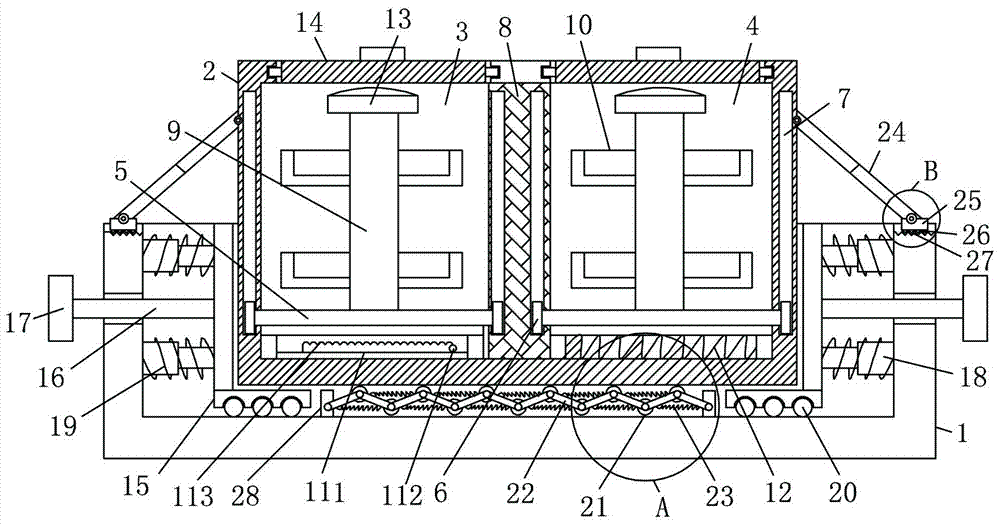

The invention discloses a paint spraying device for auto parts with fast drying effect, which comprises a box shell and a fixing plate, support legs are fixedly connected around the lower end of the box shell, and the upper end of the inner bottom wall of the box shell is A paint spray box is provided, and several spray pipes are symmetrically arranged on both sides of the inner wall of the paint spray box. The outer wall of the spray pipe is evenly connected with several atomizing nozzles, and the middle part of the fixed plate is vertically inserted with a first rotating shaft. The first rotating shaft and the second rotating shaft run through the outer wall of the downward extending end of the fixing plate and are surrounded by several hooks. The two ends of the fixing plate are symmetrically and vertically fixedly connected with connecting rods, and the connecting rods are far away from one end of the fixing plate. The limit rod is horizontally fixedly connected, and the inner wall of the limit rod is threadedly connected with a screw rod through a spiral groove. The invention is simple in structure and easy to operate, realizes the comprehensive and uniform painting of auto parts, shortens the drying time of the paint and improves the work efficiency.

Owner:湖州锦杭卡车车厢有限公司

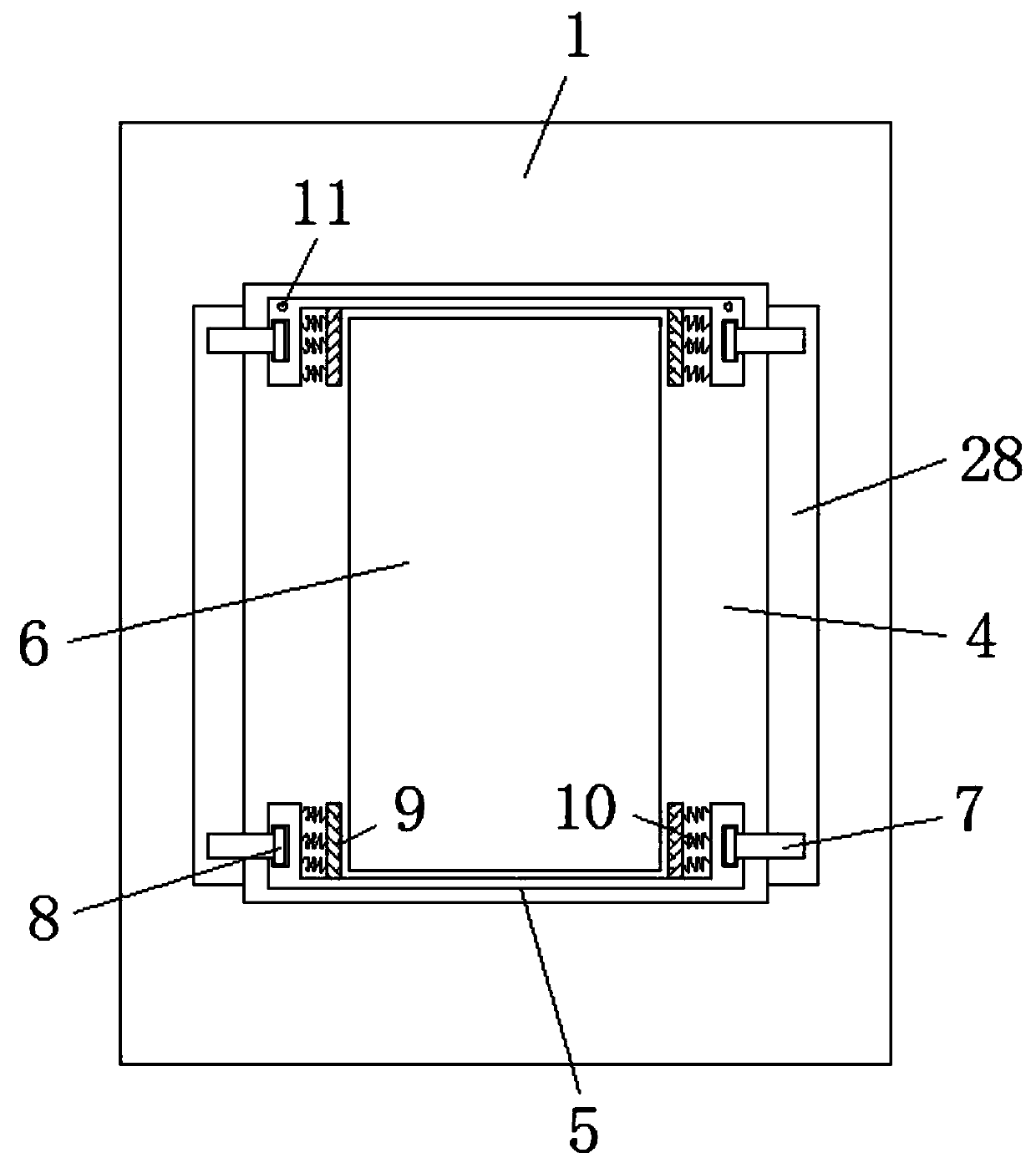

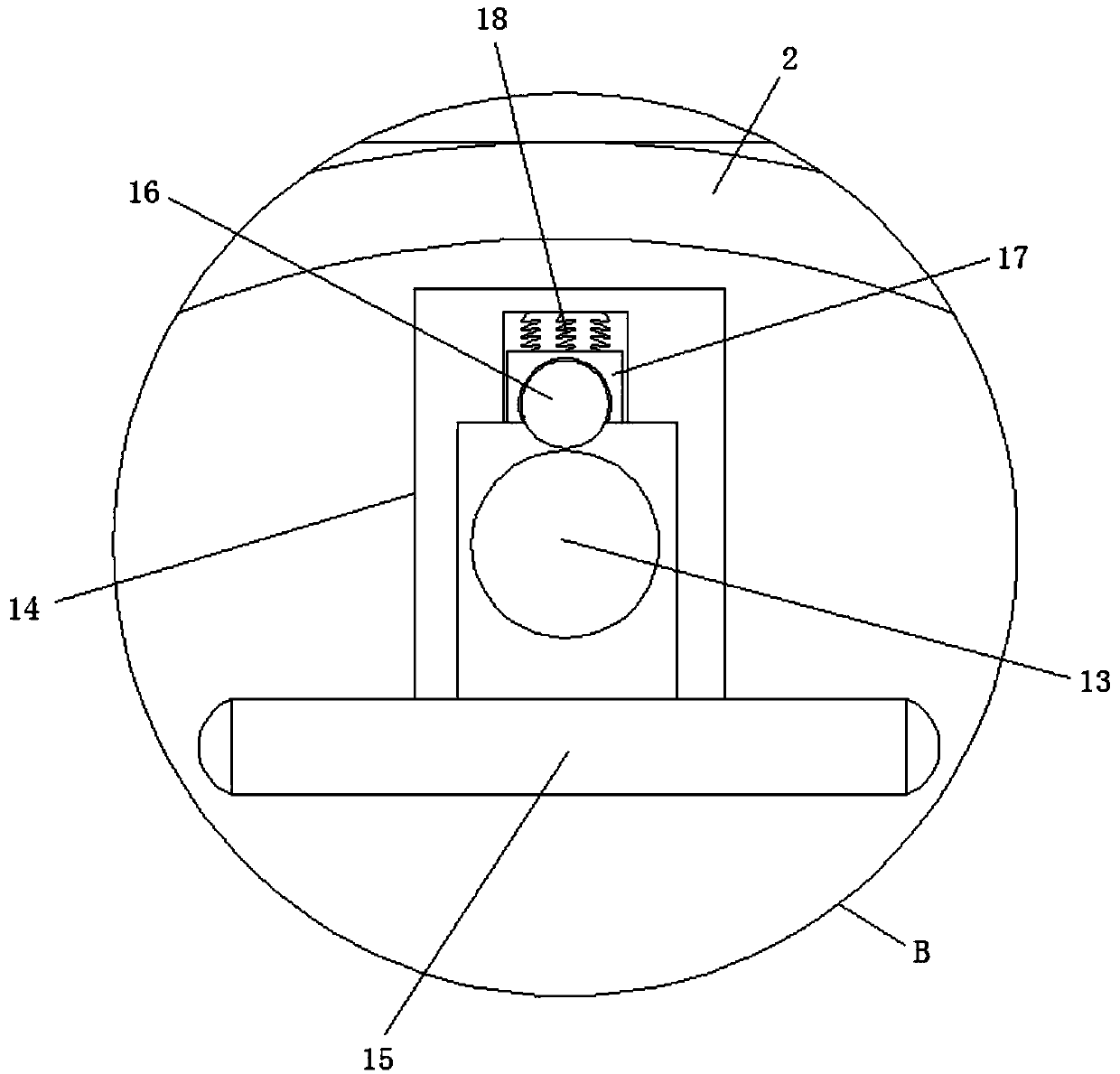

Multifunctional food safety distribution device

ActiveCN107215564AAvoid shakingIncrease frictionShock-sensitive articlesContainers to prevent mechanical damageEngineeringMultiple function

The invention discloses a multifunctional food safety distribution device which comprises a base and a distribution box. A groove is formed in the base; the distribution box is arranged in the groove; L-shaped limiting plates are symmetrically arranged on the two sides of the bottom of the distribution box; a plurality of mounting grooves are uniformly formed in the lower ends of the L-shaped limiting plates, and rolling balls are arranged in the mounting grooves correspondingly; a plurality of first telescopic rods are connected between the outer walls of the L-shaped limiting plates and the inner wall of the base, and the outer walls of the first telescopic rods are sleeved with first springs; a cold storage area and a heating area are arranged in the distribution box; pull rods are arranged in the cold storage area and the heating area correspondingly, and the bottoms of the pull rods are fixedly connected with bottom plates; and a plurality of food boxes are symmetrically arranged on the two sides of the outer walls of the pull rods. Operation is easy, using is convenient, quick and ingenious, the condition of scattering of foods in the distribution process can be effectively avoided, the distribution box is provided with a temperature control system which can control the temperature in the box in real time, the effects of cold storage and heat preservation are achieved, the safety of the foods is guaranteed, and the multifunctional food safety distribution device is suitable for wide promotion.

Owner:HENAN NORMAL UNIV

Device for washing crafts

InactiveCN107344181ATo achieve the purpose of cleaning handicraftsImprove cleaning efficiencyDrying gas arrangementsCleaning using liquidsDrive motorPiston

The invention discloses a device for washing crafts. The device comprises a body, wherein a washing tank is arranged at the bottom of the inner wall of the body, and a drive motor is arranged at the center of the top wall of the washing tank; a rotating shaft is arranged on one side of the drive motor and penetrates through the top wall of the washing tank, and the outward extending end of the rotating shaft is fixedly connected with a supporting plate; a groove is formed in the center of the upper end of the supporting plate; a plurality of cylinders are arranged on one side of the outer wall of the groove in a uniform enclosing manner, and a soft bag is communicated with the bottom of the cylinders; a piston is in threaded connection with the inner wall of each cylinder; a main pipeline is transversely spliced to the upper end of the inner wall of the body, and two ends of the main pipeline penetrate through the inner wall of the body and extend outward; a first valve and a boost pump are sequentially arranged on the pipeline, at one extending end, of the main pipeline; and a second valve is arranged on the pipeline, at the other extending end, of the main pipeline. The device is simple in structure and easy to operate, can be used for washing crafts in an omnibearing manner, has high washing efficiency, is environment-friendly, and is suitable for wide popularization.

Owner:浙江千鹤工艺品有限公司

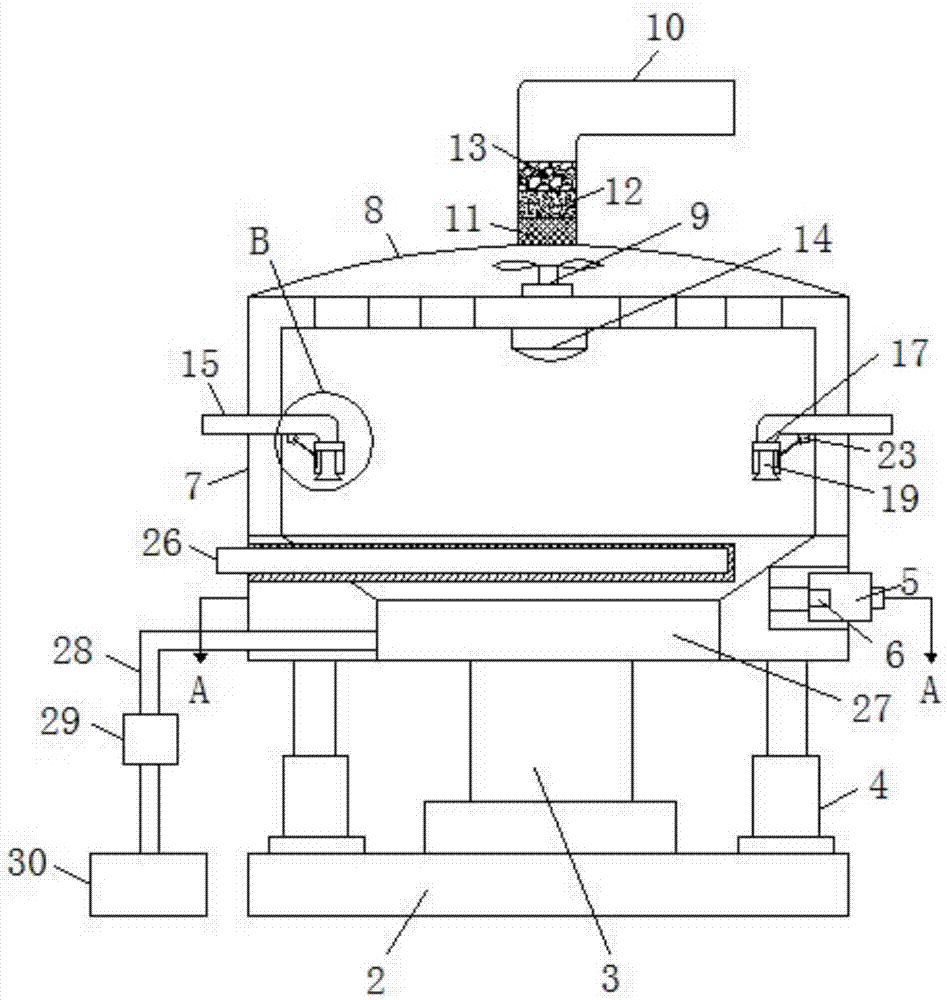

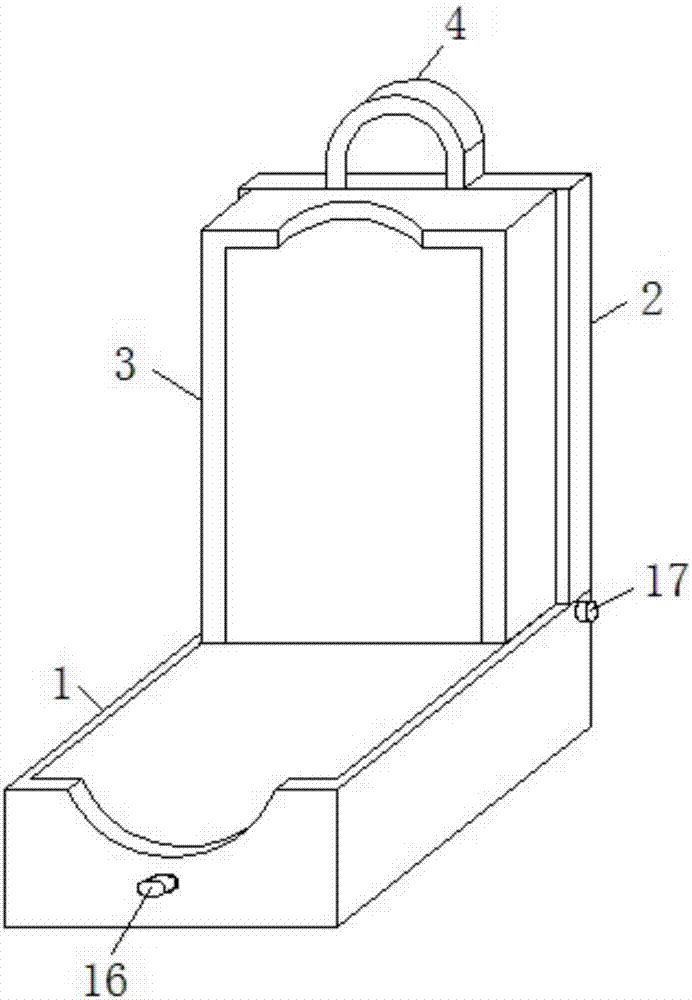

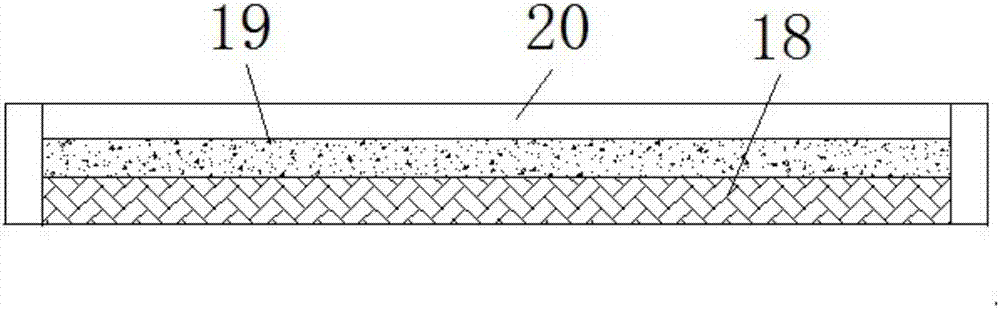

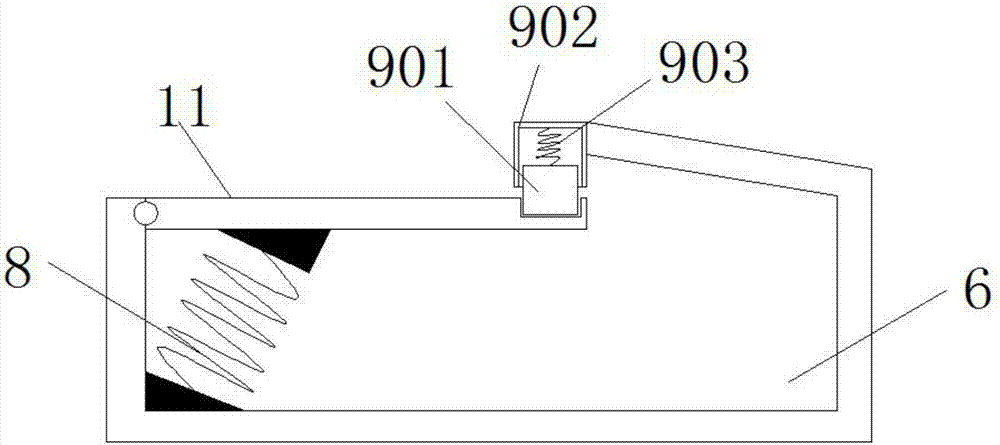

Rapidly cooling ironing table for garment processing

The invention discloses a rapidly cooling ironing table for garment processing. The rapidly cooling ironing table for garment processing comprises a working table, supporting legs are fixedly connected around the lower end of the working table, a fixing block is fixedly connected to one side of the end of the working table, and a supporting rod is fixedly connected to the upper end of the fixing block. An L-shaped support rod sleeves the outer wall of the supporting rod, a pressing plate is fixedly connected to the end, away from the supporting rod, of the L-shaped supporting rod, a pluralityof exhausting vent holes are evenly communicated with the inner wall of the working table, a water recovery tank is communicated with the lower end of an exhausting funnel through a radiating barrel,and a conduit is communicated with one side of the outer wall of the radiating barrel. A water pumping pipe is communicated with one side of the outer wall of the lower end of the water recovery tank,a booster pump is arranged on a pipeline of the water pumping pipe, and an iron placing rack is fixedly connected to the other side of the end of the working table. The rapidly cooling ironing tablefor garment processing has the advantages of being simple in structure and easy to operate, and capable of rapidly radiating and cooling high-temperature steam generated during ironing, recycling of recycled water and saving water resources.

Owner:湖州翔顺工贸有限公司

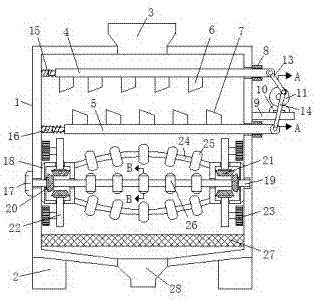

Powerful building material crushing device

InactiveCN107243391AImprove crushing effectSimple structureGrain treatmentsArchitectural engineeringDrive motor

The invention discloses a powerful building material crushing device. The powerful building material crushing device comprises a machine shell. A fixing plate is arranged on one side of the outer wall of the machine shell. A first drive motor is arranged at the upper end of the fixing plate. One end of the first drive motor is fixedly connected with a disc through a rotation shaft, and one side of the outer wall of the disc is rotationally connected with a first connecting rod and a second connecting rod through an eccentric shaft. The end, away from the eccentric shaft, of the first connecting rod is rotationally connected with a first cutting rod, and a plurality of upper blades are arranged at the lower end of the first cutting rod. The end, away from the eccentric shaft, of the second connecting rod is rotationally connected with a second cutting rod, and a plurality of lower blades are arranged at the upper end of the second cutting rod. A second drive motor is arranged on one side of the outer wall of the machine shell. A rotating shaft is fixedly connected to one side of the second drive motor, and a plurality of sets of crushing blades are arranged on the outer wall of the rotating shaft in a surrounding manner. The powerful building material crushing device is simple in structure, crushing is conducted after cutting, and the crushing effect is guaranteed while the work efficiency is improved.

Owner:长兴县太湖编织袋有限公司

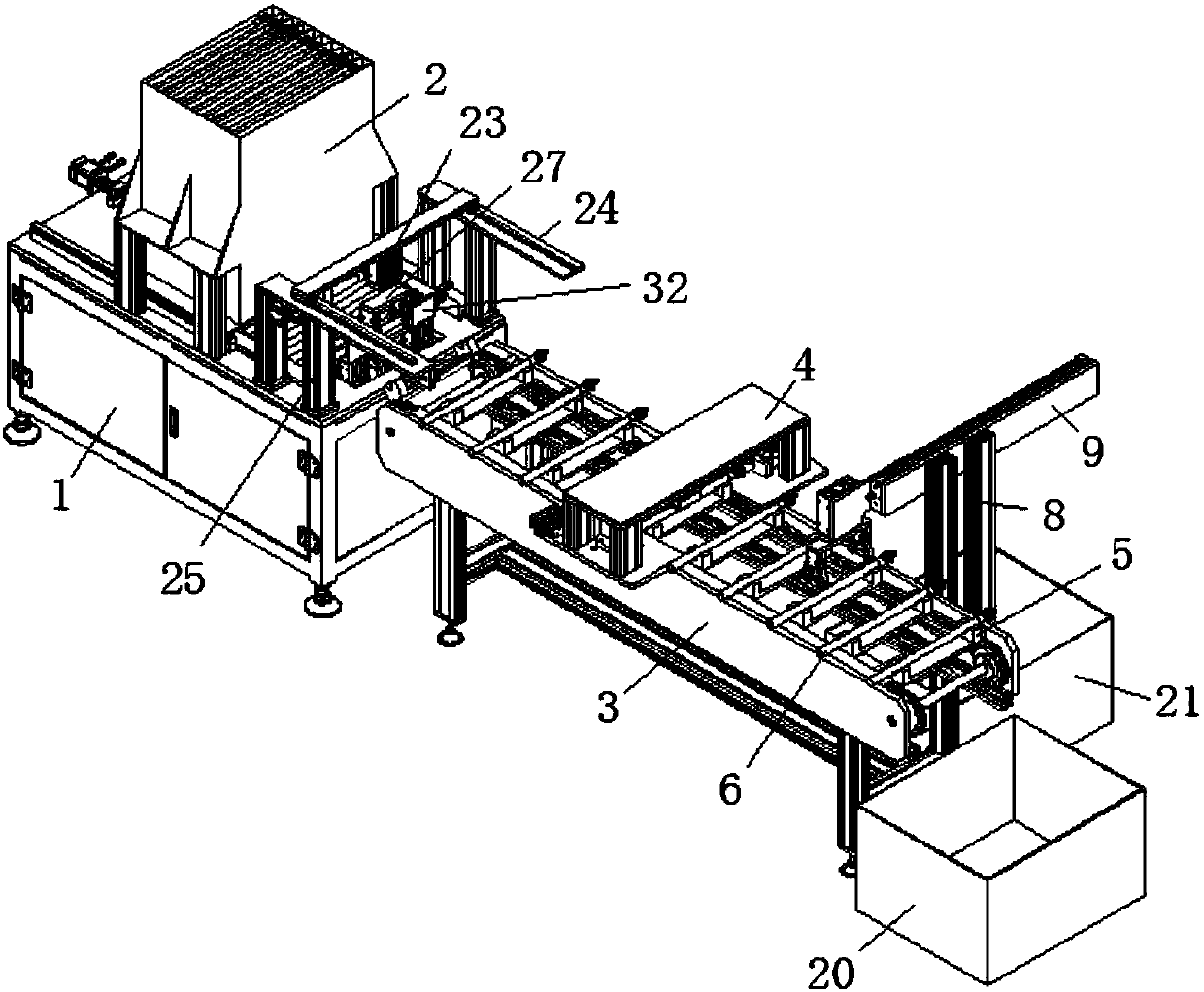

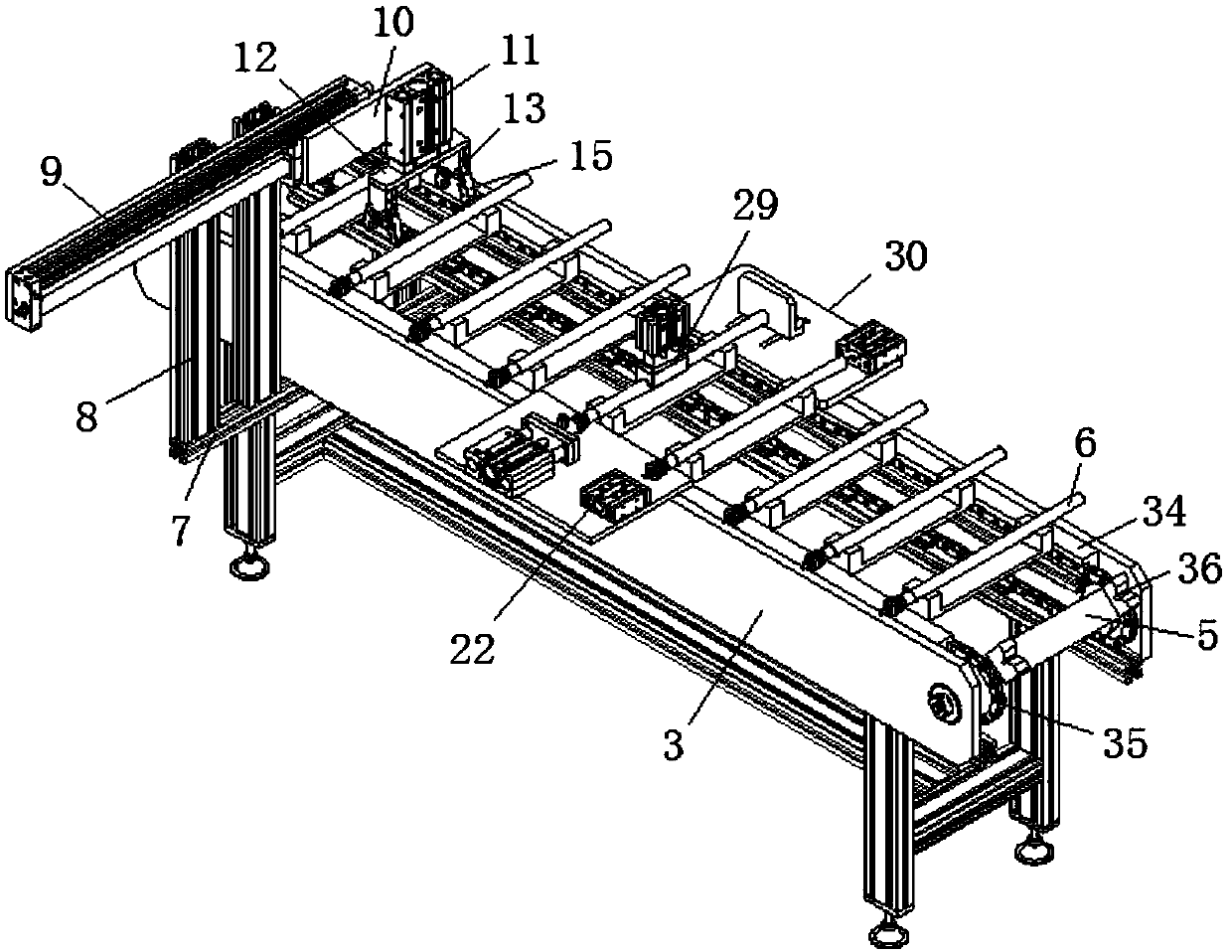

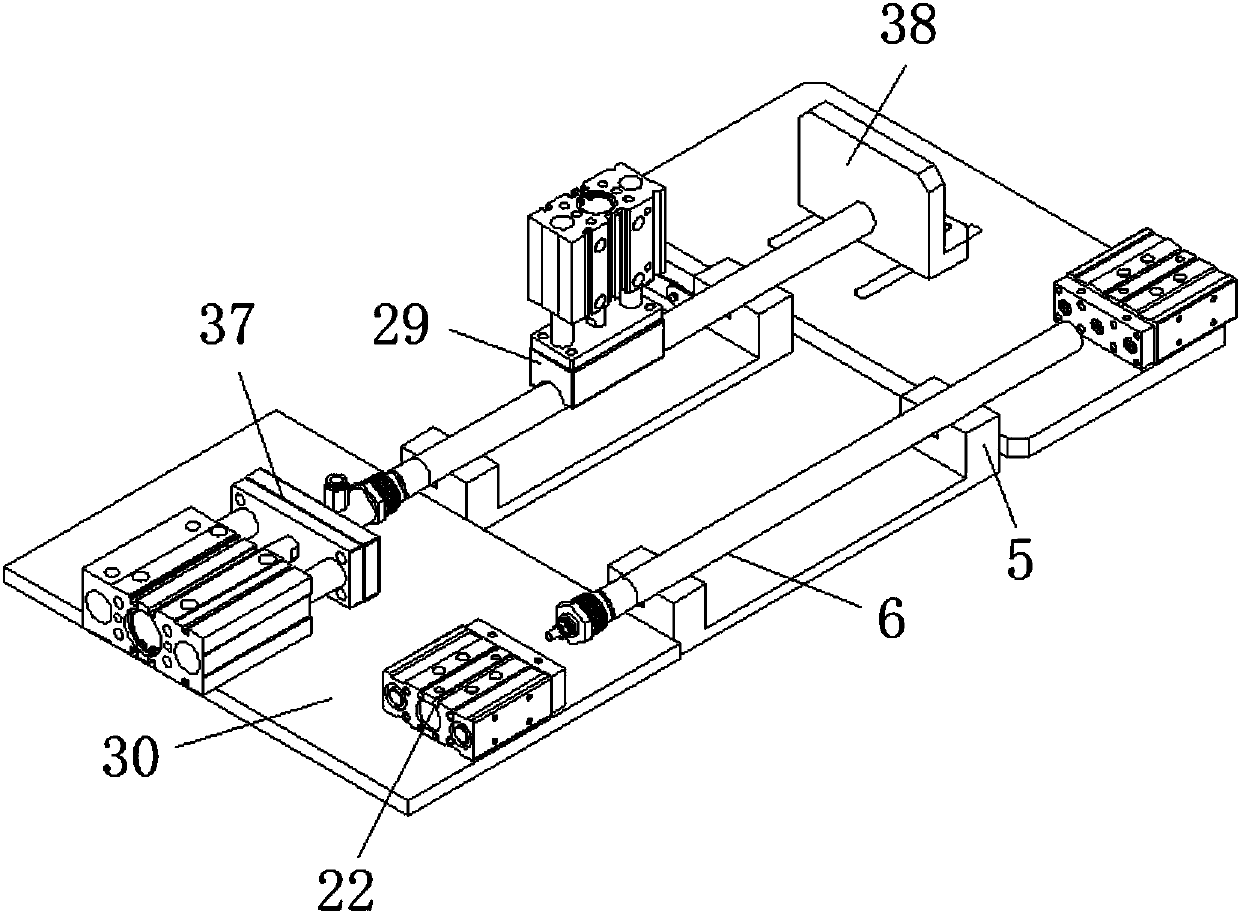

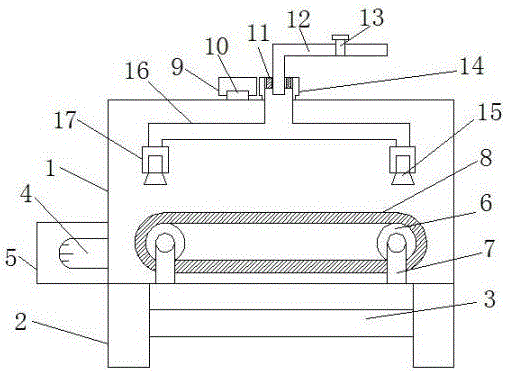

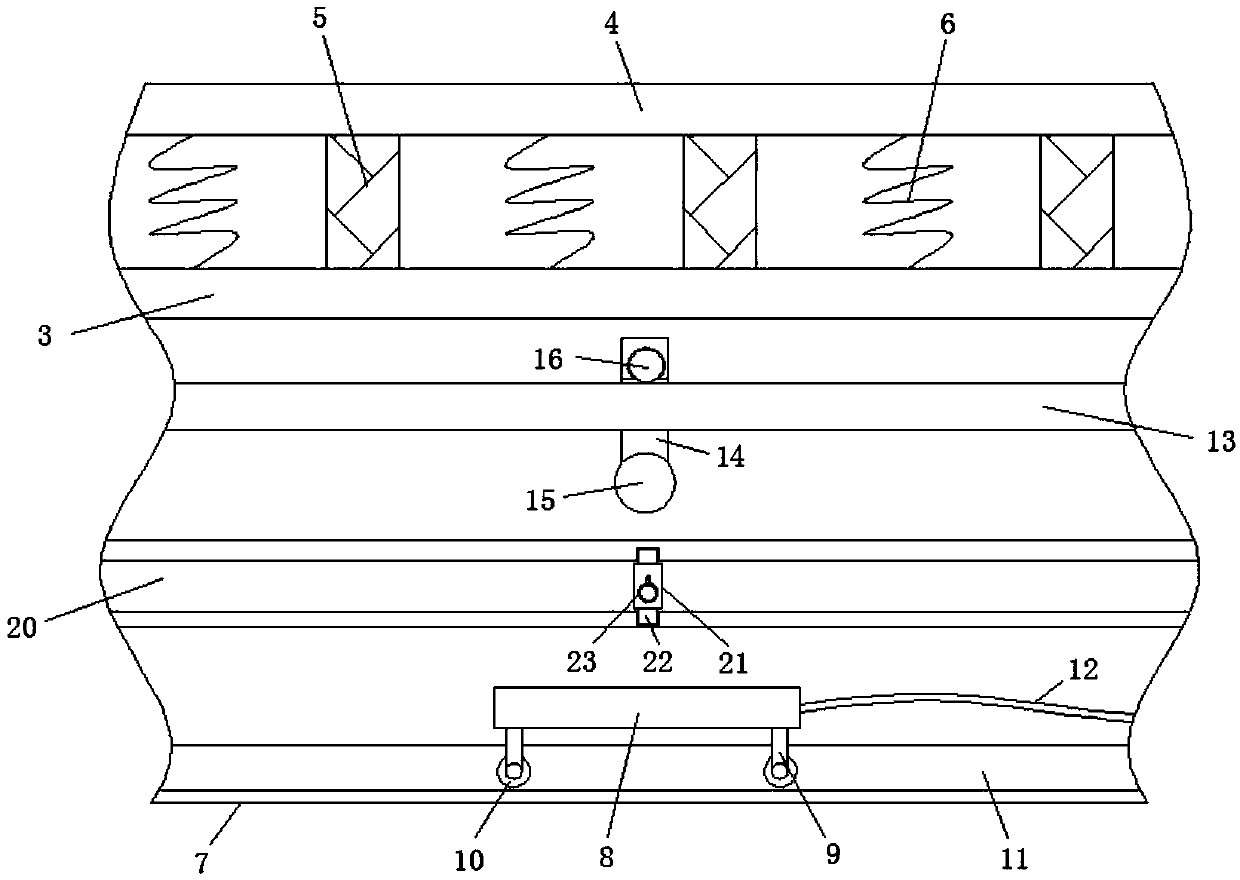

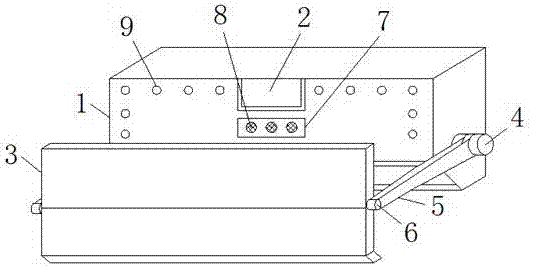

Device for automatic testing of insulation and leakage of electrode bars of electric appliances

ActiveCN107561105AImprove stabilityHigh degree of automationTesting dielectric strengthMaterial analysis by transmitting radiationEngineeringAutomatic testing

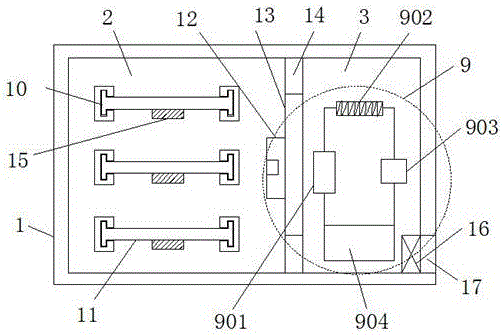

The invention discloses a device for automatic testing of insulation and leakage of electrode bars of electric appliances. The device comprises a working table, a discharging box is arranged at the upper end of the working table, a conveying device is arranged on one side of the working table, and a plurality of brackets are evenly arranged on a conveying track of the conveying device; the electrode bars to be tested are installed at the upper ends of the brackets through installation grooves, a detection mechanism is installed on one side of the upper end of the transmission device, and a fixed support is installed on one side of the detection mechanism and located on the bottom of the conveying device; a supporting frame is fixedly connected to one side of the upper end of the fixed support, a guide rail is fixedly connected to one side of the outer wall of the upper end of the supporting frame, and a translation plate is slidably connected to one side of the outer wall of the guiderail through a track; and an installation plate is fixedly connected to the lower end of a first cylinder through a piston rod, and ball and socket joints are symmetrically arranged on the two sides of the lower end of the installation plate. The device is simple in structure and easy to operate, automatic testing of the electrode bars is realized, production efficiency is improved, and labor force is reduced.

Owner:JIANGSU HUAJUE TESTING TECH

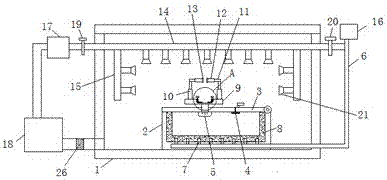

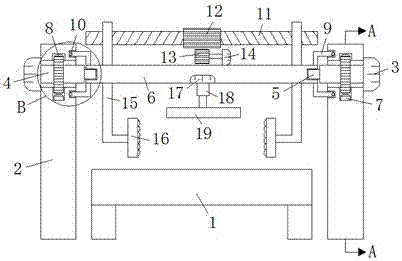

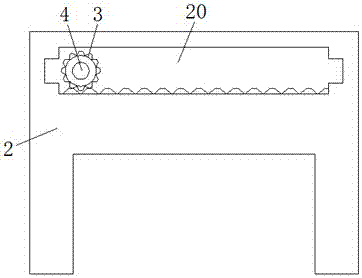

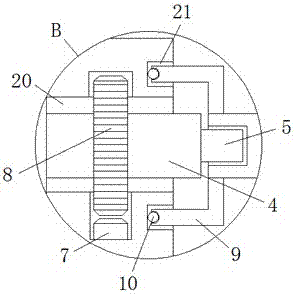

Corrugated paper indentation device for producing packaging box

InactiveCN107672233AReduce lossPrevent deviationMechanical working/deformationGear wheelStructural engineering

The invention discloses a corrugated paper indentation device for producing a packaging box. The corrugated paper indentation device comprises a workbench. Fixing frames are symmetrically and fixedlyconnected to the two sides of the upper end of the workbench. Horizontal movement grooves are formed in one sides of the inner walls of the fixing frames. A walking frame is connected between the twohorizontal movement grooves in a sliding manner. A movable shaft is inserted and connected in each movable groove, wherein the outer wall of the movable shaft is in threaded connection with an annularclamping block, one side of the upper end of the annular clamping block is in engaged connection with a bevel gear, and a connecting rod is connected between the two bevel gears. The outer wall of the middle portion of the connecting rod is in cup joint with a first gear, the upper end of the first gear is in engaged connection with a second gear, a fixing block is arranged at the lower end of each movable shaft, the lower end of each fixing block is provided with a downward pressing wheel through a rotation groove, and a cross rod is horizontally inserted and connected in each downward pressing wheel. The corrugated paper indentation device is simple in structure and easy to operate, losses generated during indentation can be effectively reduced, meanwhile, friction force is reduced, theindentation effect is improved, and the device is convenient and ingenuous to use and suitable for wide popularization.

Owner:泰州市嘉新包装制品有限公司

Novel anti-impact vibration reduction device for excavator cab

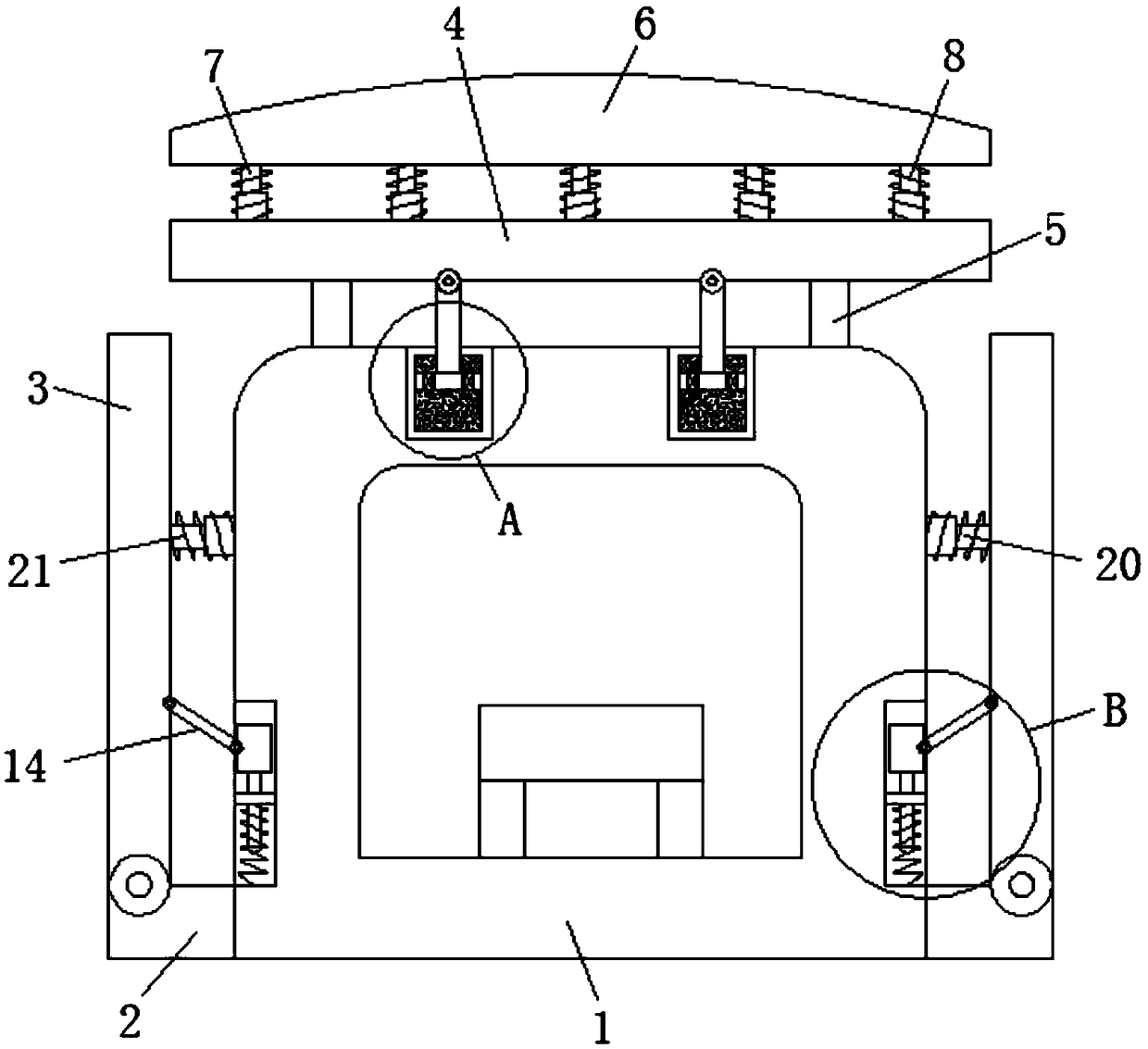

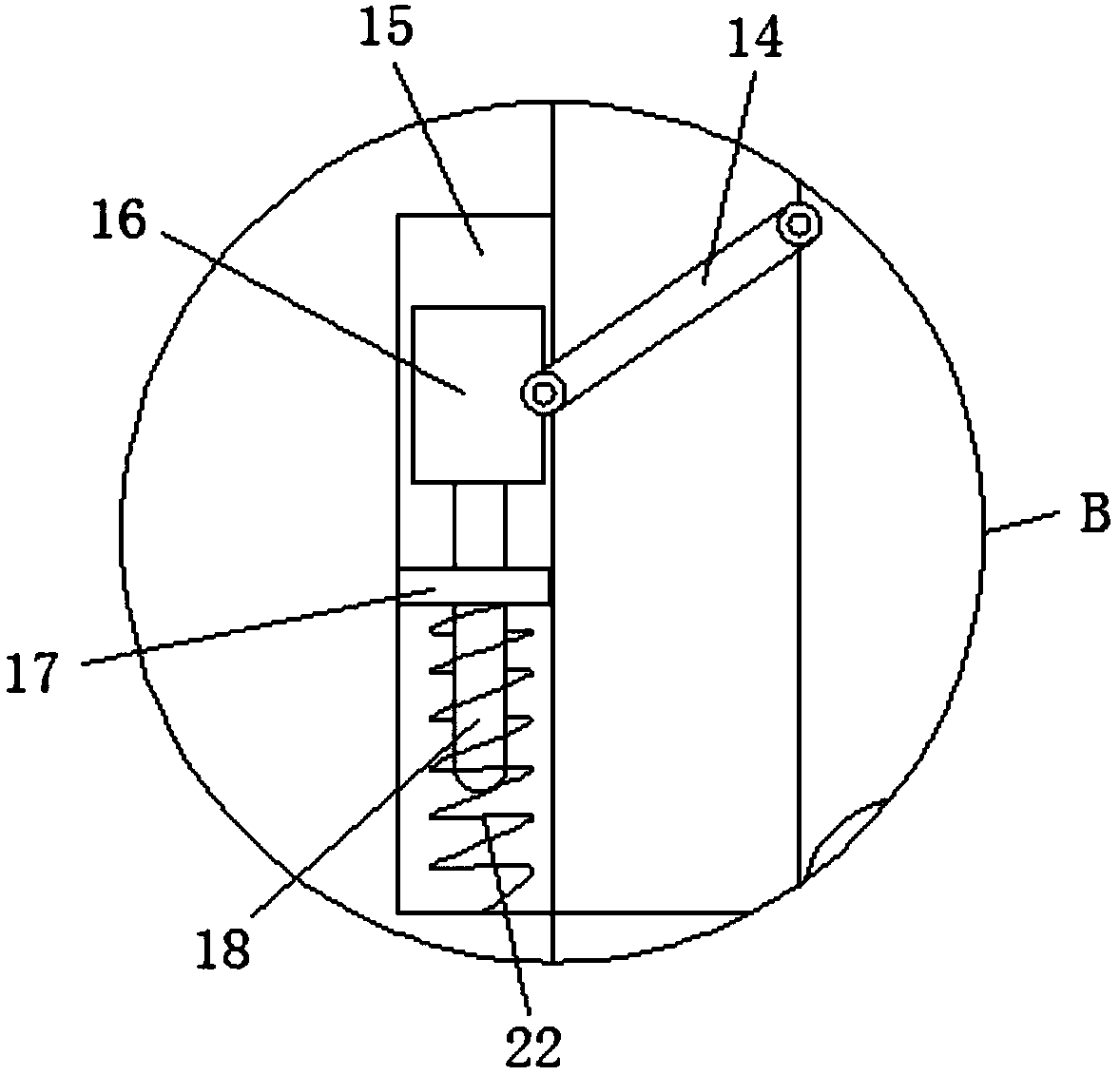

InactiveCN108385764AReduce impact damageAvoid injurySoil-shifting machines/dredgersEngineeringExcavator

The invention discloses a novel anti-impact vibration reduction device for an excavator cab. The novel anti-impact vibration reduction device comprises a cab body. Multiple support pillars are fixedlyconnected to the top of the cab body, and a top plate is fixedly connected to the top ends of the support pillars. An elastic protection plate is connected to the upper end of the top plate through multiple first extending-and-contracting rods, and a first spring is connected to the outer wall of each first extending-and-contracting rod in a sleeving manner. Movable grooves are symmetrically formed in the two sides of the outer wall of the cab body, and a sliding block is connected into each movable groove in a sliding manner. A support rod is connected to one side of the outer wall of each sliding block in a rotary manner. The end, far away from the corresponding sliding block, of each support rod is connected with the outer wall of a corresponding protection side plate in a rotary manner. A limiting rod is fixedly connected to the bottom of each sliding block, and a third spring is connected outside each limiting rod in a sleeving manner. The novel anti-impact vibration reduction device is simple in structure and easy to operate; impact damage which the cab is subjected to can be effectively reduced; a driver is prevented from being injured; and the device is convenient, fast and ingenious to use and suitable for being widely popularized.

Owner:CHANGAN UNIV

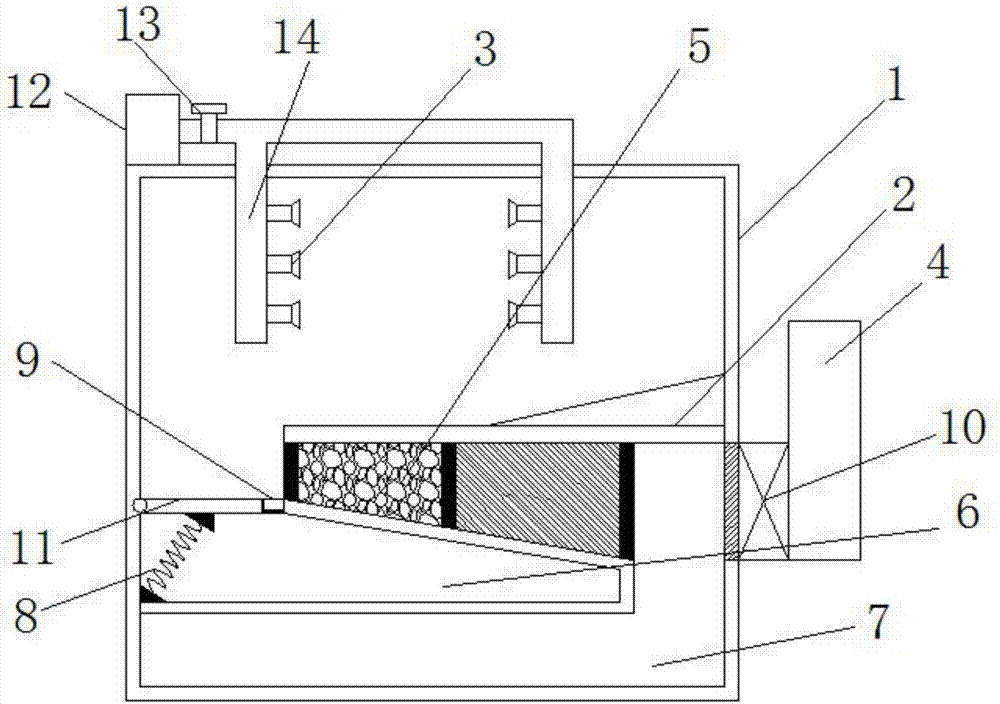

Multifunctional cleaning drying device for garment making

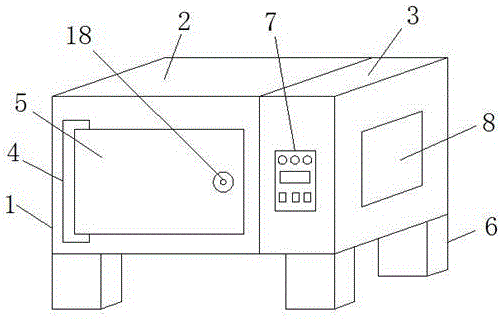

InactiveCN107938243APrevent fallingAvoid Spinning SpraysOther washing machinesOther drying apparatusEngineeringLaundry

The invention discloses a multi-functional cleaning and drying device for garment processing, which comprises a fixing frame, the upper end of the fixing frame is fixedly connected with an organic body casing, and a drying device is fixedly connected with one side of the outer wall of the body casing, and the drying device The upper and lower ends of one side are respectively connected with an air outlet and an air inlet. The inner wall of the fixed frame is vertically inserted with a rotating shaft, and the top of the rotating shaft is fixedly connected with a turntable. A set of hooks, a first water inlet pipe is vertically inserted into the center of the upper end of the turntable, a number of first nozzles are connected to one side of the outer wall of the first shunt pipe, and a circular bottom plate is fixedly sleeved on the outer wall of the lower end of the rotating shaft. A side of the outer wall of the second branch pipe is connected with several second spray heads, and one end of the second branch pipe is connected with a second water inlet pipe. The invention has a simple structure and is easy to operate, realizes washing and drying of clothes without damaging the clothes, and improves work efficiency.

Owner:湖州翔顺工贸有限公司

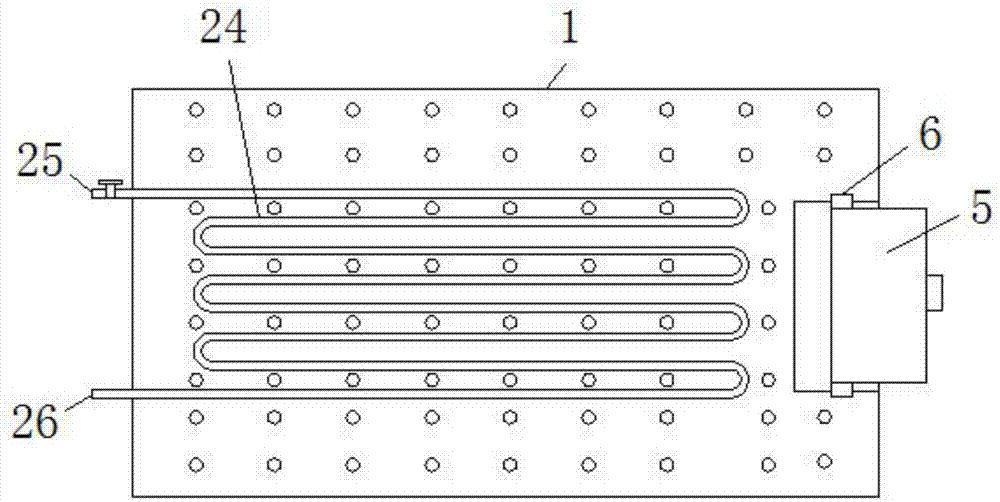

Multifunctional drying device for textile fabric

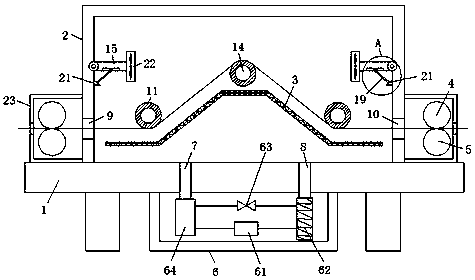

InactiveCN107702495AFull sweepRealize cycle dryingDrying gas arrangementsDrying machines with progressive movementsEngineeringTextile

The invention discloses a multifunctional drying device for textile fabric. The multifunctional drying device for the textile fabric comprises a workbench. The upper end of the workbench is fixedly connected with a machine body shell. An upper traction roller and a lower traction roller are installed on the inner wall of a mounting frame. A plurality of rotating rollers are evenly distributed on the inner wall of the machine body shell in a staggered mode. The two sides of the inner wall of the machine body shell are symmetrically and rotationally connected with motion bars, and a fan is arranged at the end, away from the machine body shell, of each motion bar. Each inclined block is fixed to one side of the inner wall of the machine body shell. The textile fabric is arranged inside the machine body shell. The textile fabric enters the machine body shell from a feeding inlet, sequentially passes through the multiple rotating rollers and is discharged from a discharging outlet. A dryingbox is installed at the bottom of the workbench. The multifunctional drying device for the textile fabric is simple in structure and easy to operate, achieves circular drying of the textile fabric, improves drying efficiency, meanwhile, does not damage the textile fabric, and improves the quality of products.

Owner:湖州佳伟纺织品有限公司

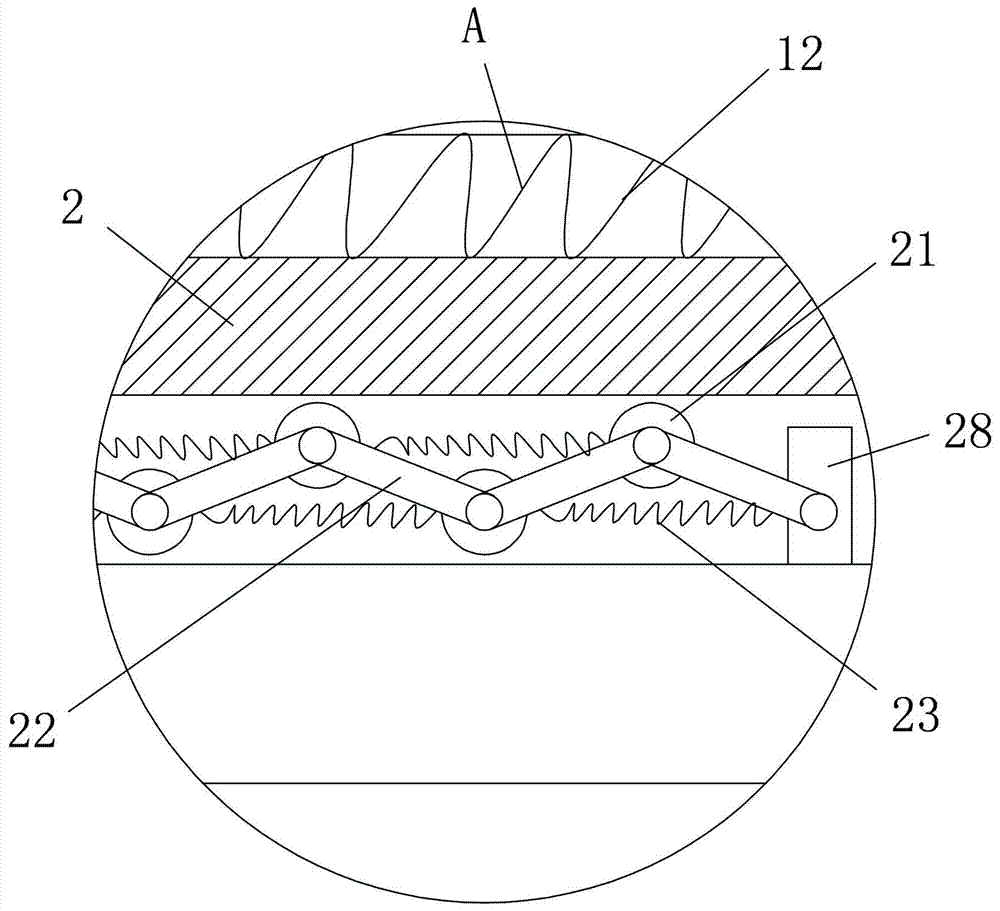

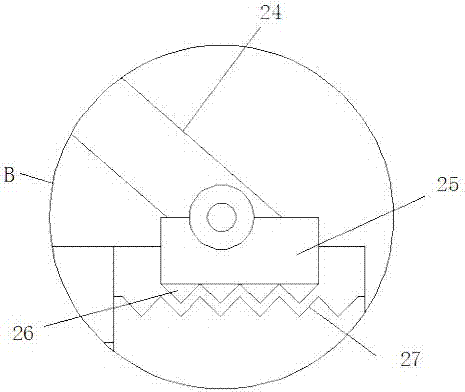

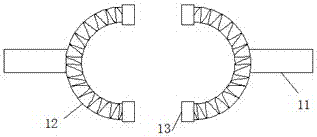

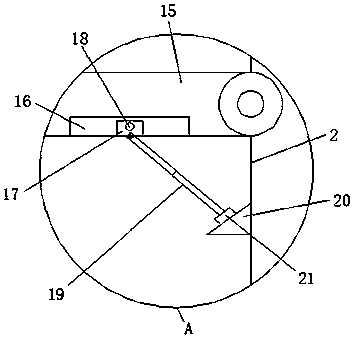

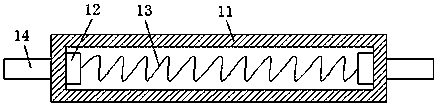

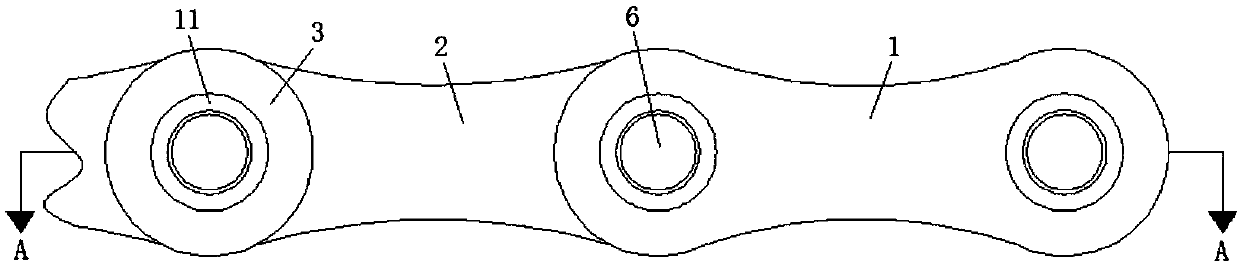

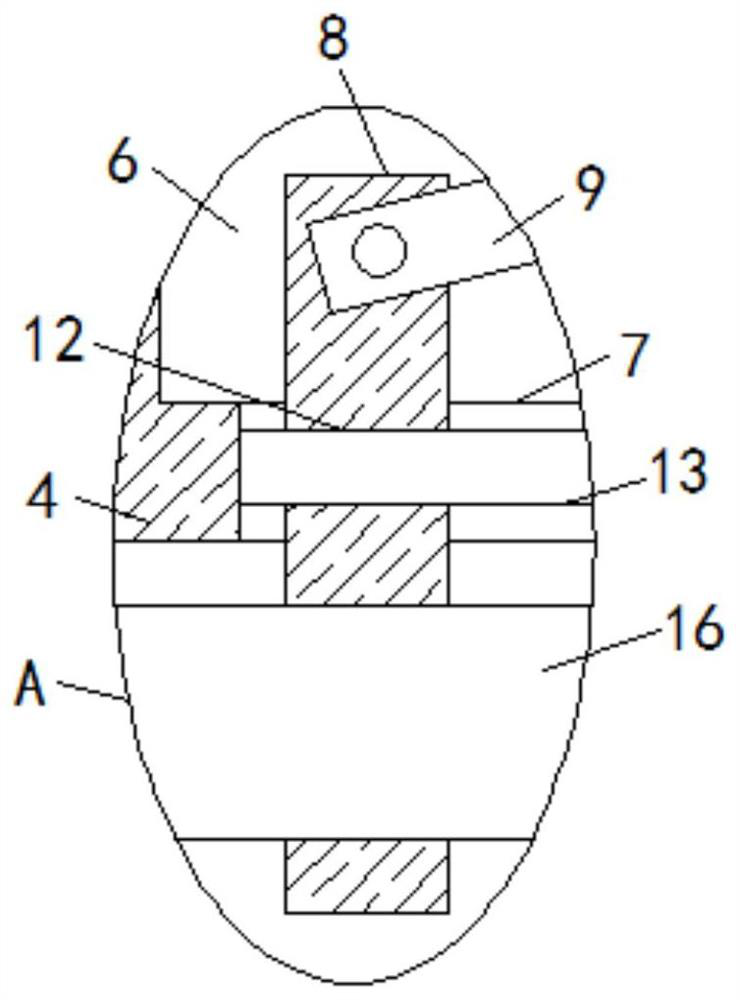

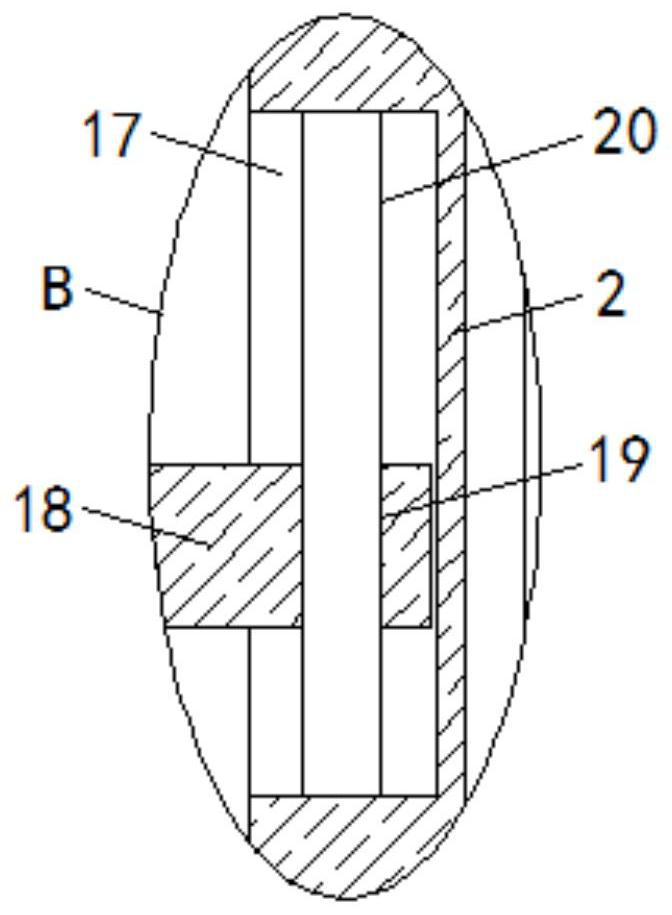

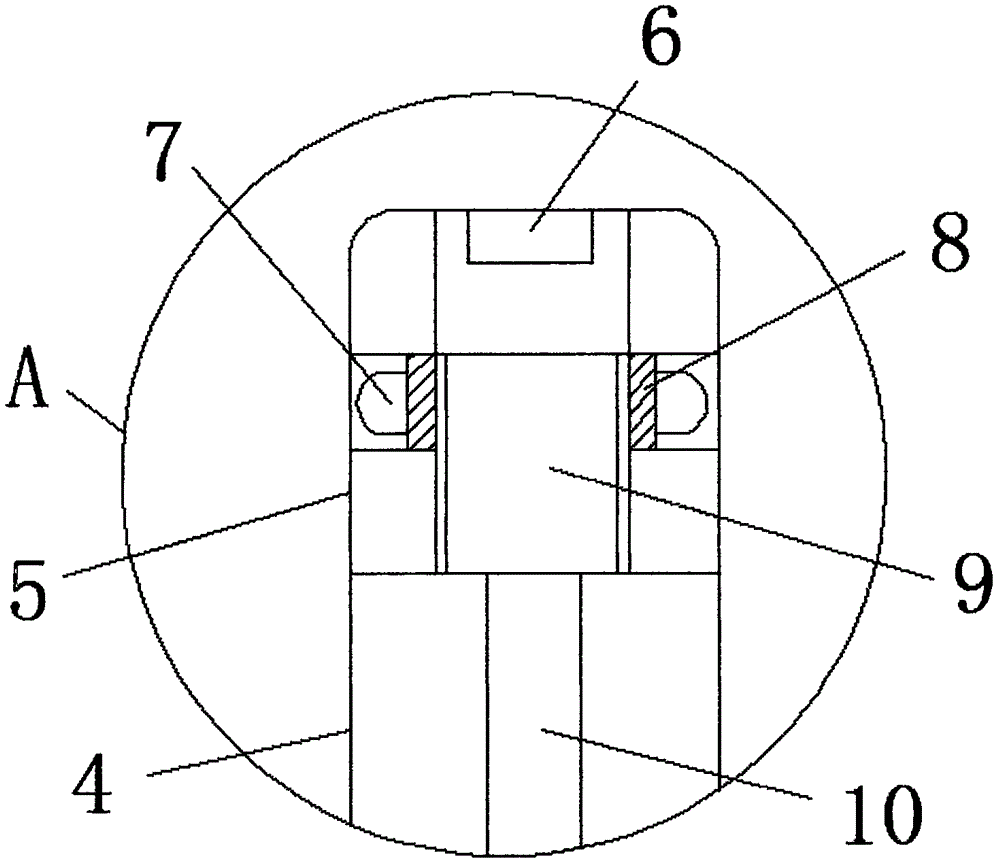

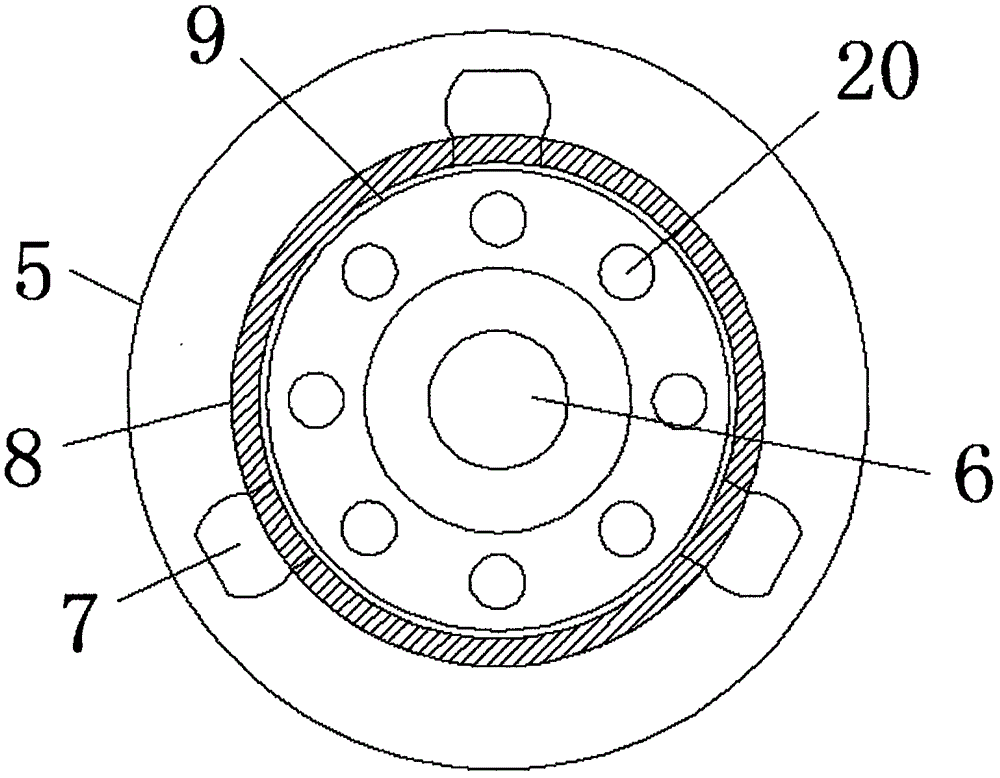

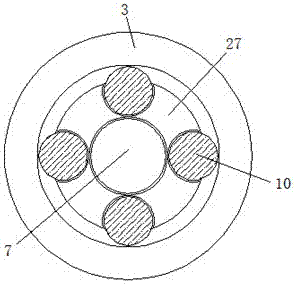

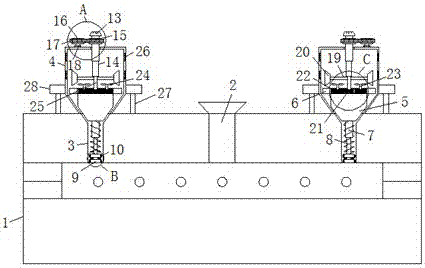

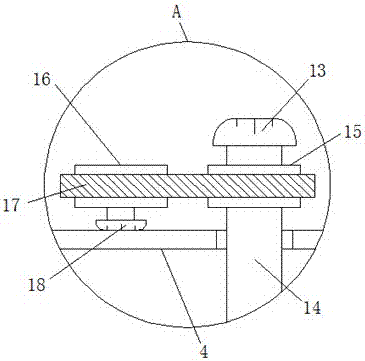

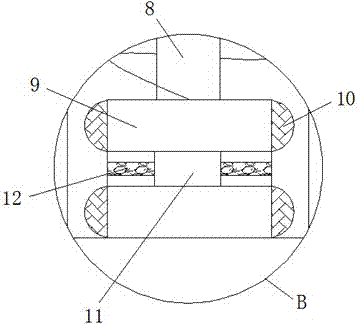

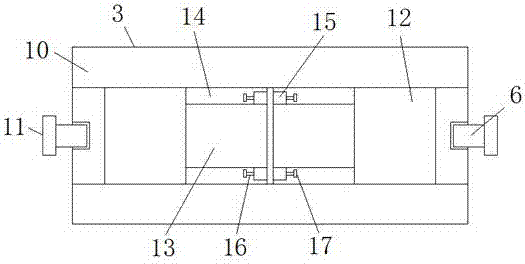

Structure improved chain

The invention discloses a structure improved chain. The structure improved chain comprises a plurality of groups of main chain plates and a plurality of groups of auxiliary chain plates, wherein boththe number of each group of main chain plates and the number of each group of auxiliary chain plates are two, the two main chain plates in each group are arranged in a directly facing manner, and thetwo auxiliary chain plates in each group are arranged in a directly facing manner; the main chain plates and the auxiliary chain plates are distributed in a staggering manner; the two sides of the outer wall of each auxiliary chain plate are symmetrically and fixedly connected to connecting plates; movable grooves corresponding to the connecting plates are formed in the outer wall of each main chain plate; two symmetrical sleeves are fixedly connected between the two main chain plates facing to each other directly; the outer walls of the sleeves are in sleeve connection with rollers; the two sides of the outer wall of the middle of each sleeve are symmetrically and fixedly connected to convex blocks; a plurality of balls are uniformly arranged on the outer wall of each roller in a surrounding manner; a pin shaft penetrates the main chain plates, the connecting plates and the sleeves; the outer wall of one end of the pin shaft is in sleeve connection with an annular fixture block; and one end, far away from the annular fixture block, of the pin shaft, is in threaded connection with a nut. The structure improved chain has the beneficial effects that the structure improved chain is simple in structure and easy to operate; the frictional force is reduced; the biting of a chain wheel and the chain is facilitated; and the service life of the structure improved chain is prolonged.

Owner:泰州亚东链条有限公司

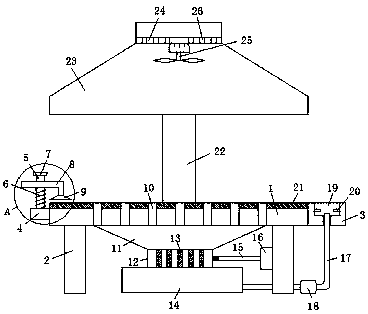

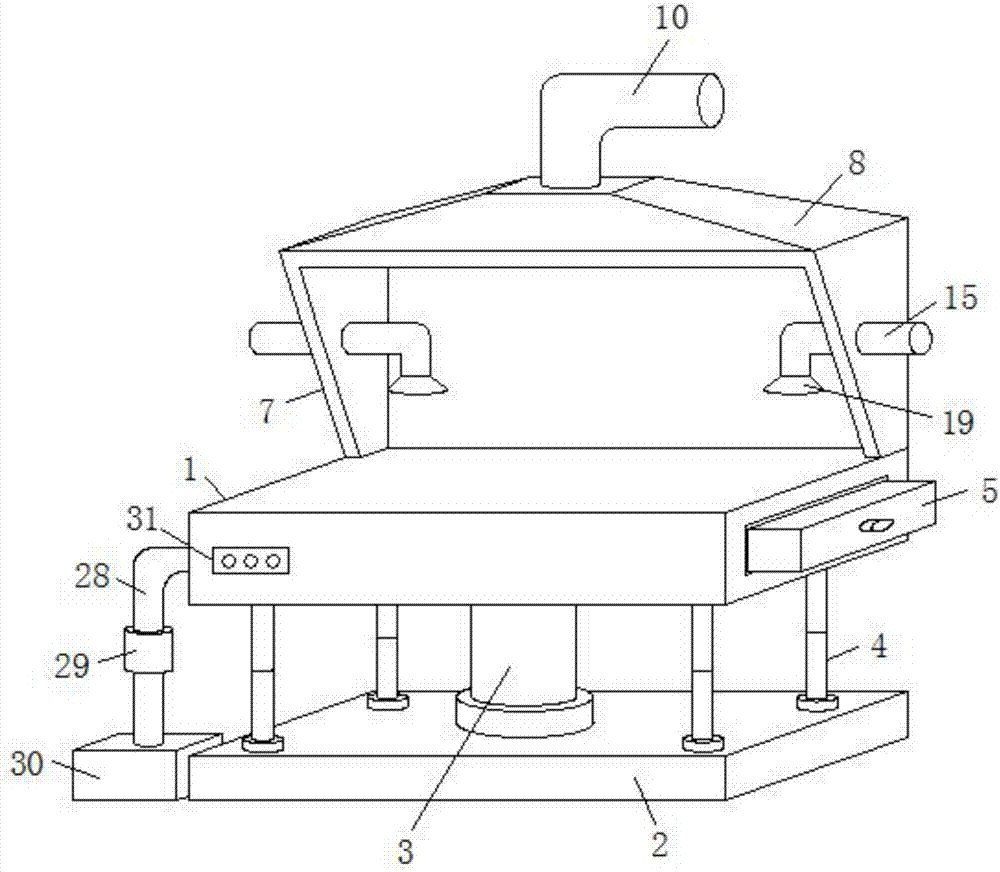

Multifunctional dissecting table for human dissection

The invention discloses a multifunctional dissecting table for human dissection. The multifunctional dissecting table comprises a dissecting table, the lower end of which is provided with a hydraulic elevating device. One end, away from the dissecting table, of the hydraulic elevating device is provided with a base. A groove is provided therein with a first chute corresponding to a first sliding block. A condensing pipe is laid into the dissecting table which is provided therein with a drainage funnel. One end, away from the drainage funnel, of a drainage pipeline is provided with a collection box. The upper end of the dissecting table is provided with an air suction cover. The upper end of the top wall of the air suction cover is provided with an air exhaust. The lower end of the top wall of the air suction cover is provided with an illuminating lamp. Two sides of the air suction cover are symmetrically connected with water pipes. The lower end of a connecting block is fixedly connected with a sleeve in which a nozzle is arranged. One end of a second sliding block is connected with an electric telescopic rod. The multifunctional dissecting table is simple in structure and easy to operate, and has functions of cleaning, collecting waste liquids and removing waste gases such that the overall dissecting work is more convenient.

Owner:西安医学高等专科学校

High-efficiency automatic cleaning device of numerical control machine tool

InactiveCN106425670ADoes not affect fixationImprove cleaning efficiencyMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a high-efficiency automatic cleaning device of a numerical control machine tool. The device comprises a machine body shell; symmetric support frames are arranged on two sides of the lower end of the machine body shell; a transverse frame is arranged between the two support frames; a conveying belt is arranged between two rotating shafts; two water separation pipes perpendicular to a water spraying pipe are arranged at an extension end of the water spraying pipe; connecting sleeves are arranged at one ends of the two pipes; rotating blocks are respectively arranged on two sides of extension ends of the two pipes; nozzles are arranged at one ends, near the rotating blocks, of the two pipes; second grooves are symmetrically formed in one sides of the two connecting sleeves; slide blocks are arranged in the two second grooves; extension rods are fixedly connected to the two slide blocks; a bearing is sleeved in the pipe wall of one end, near a notch, of the water spraying pipe; and a water inlet pipe is inserted in the bearing. The device is simple in structure, easy to operate and high in cleaning efficiency, realizes multi-angle and multi-direction cleaning, is convenient and skillful in use, and is suitable for wide popularization.

Owner:合肥齐飞信息技术有限公司

Automatic turning device used for workpiece spraying

The invention discloses an automatic turning device used for workpiece spraying. The automatic turning device used for workpiece spraying comprises a workbench. Supporting frames are symmetrically andfixedly connected to the two sides of the upper end of the workbench. A workpiece groove is formed in the inner wall of the workbench, and two concave fixing frames are symmetrically arranged in theworkpiece groove. The two sides of the inner wall of each concave fixing frame are each connected with clamping blocks through a plurality of springs. A movable rod is fixedly connected to one side ofeach round fixture block. Moving grooves corresponding to the movable rods are formed in the inner wall of the workpiece groove. Pull ropes are symmetrically connected to the two sides of the upper end of one concave fixing frame, and a rotary shaft is arranged at the ends, penetrating through a fixing plate and extending outwards, of the pull ropes. A spraying pipe is connected to the lower endof a movable block through a supporting column, and the bottom of the spray pipe evenly communicates with a plurality of spraying heads. The automatic turning device used for workpiece spraying is simple in structure, easy to operate and capable of stably and reliably turning large-area workpieces; and meanwhile, labor is saved, and the production efficiency is improved.

Owner:泰州市嘉新包装制品有限公司

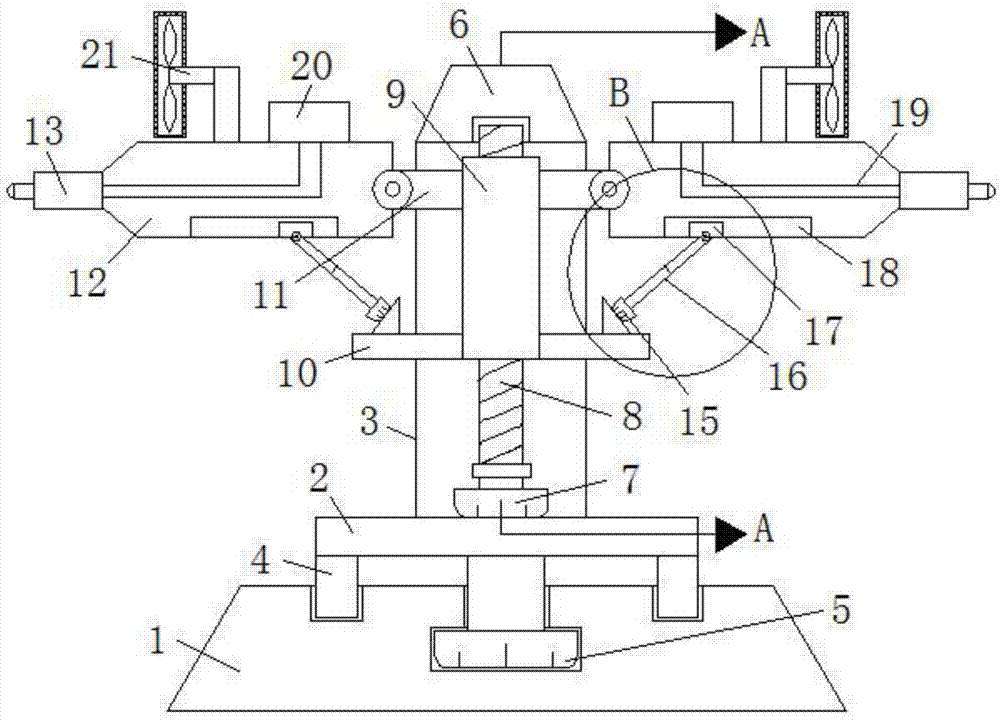

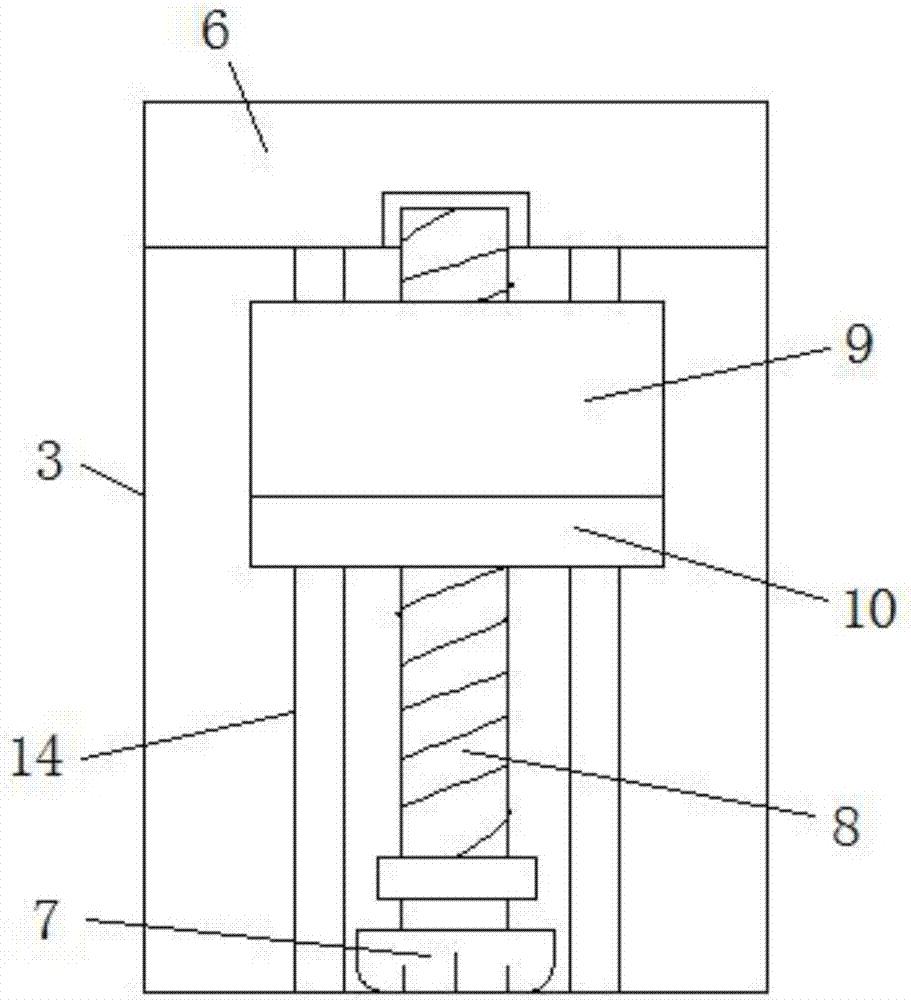

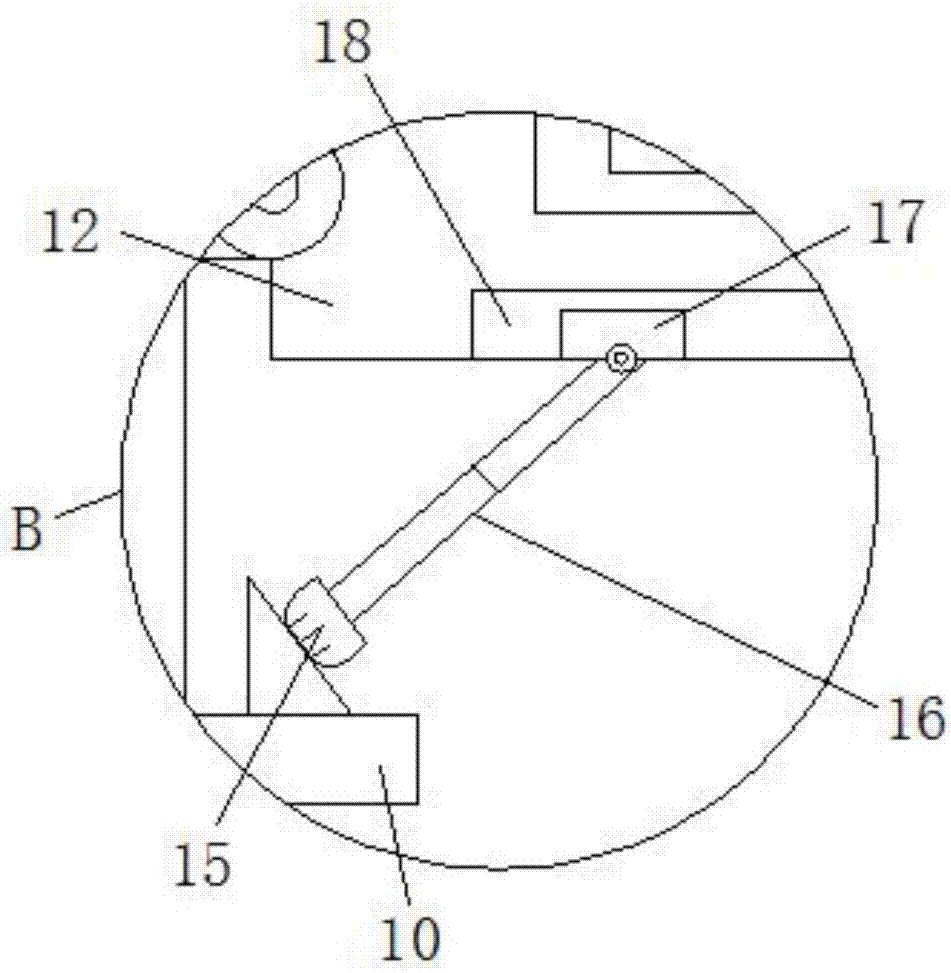

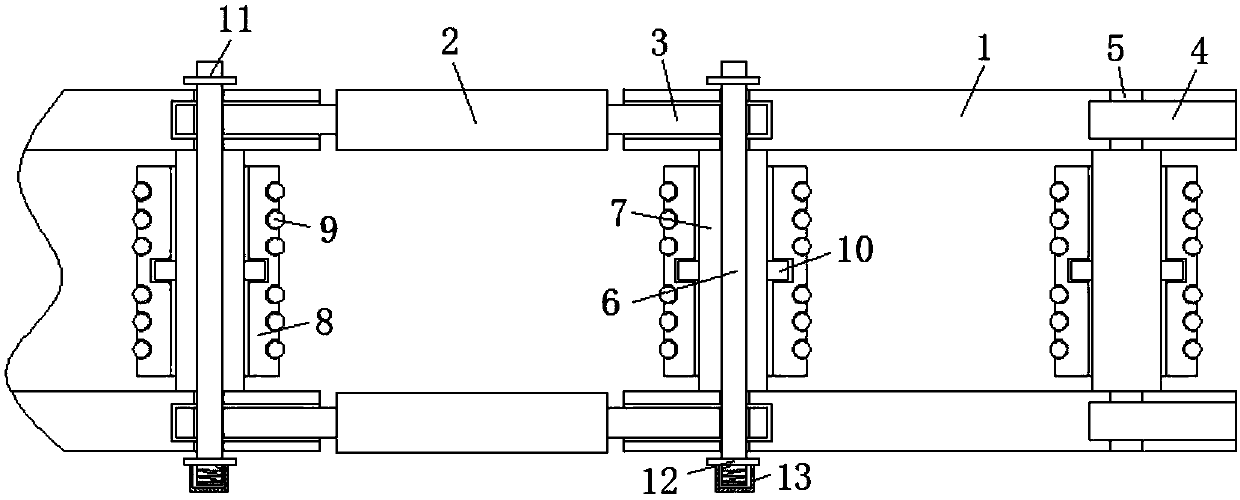

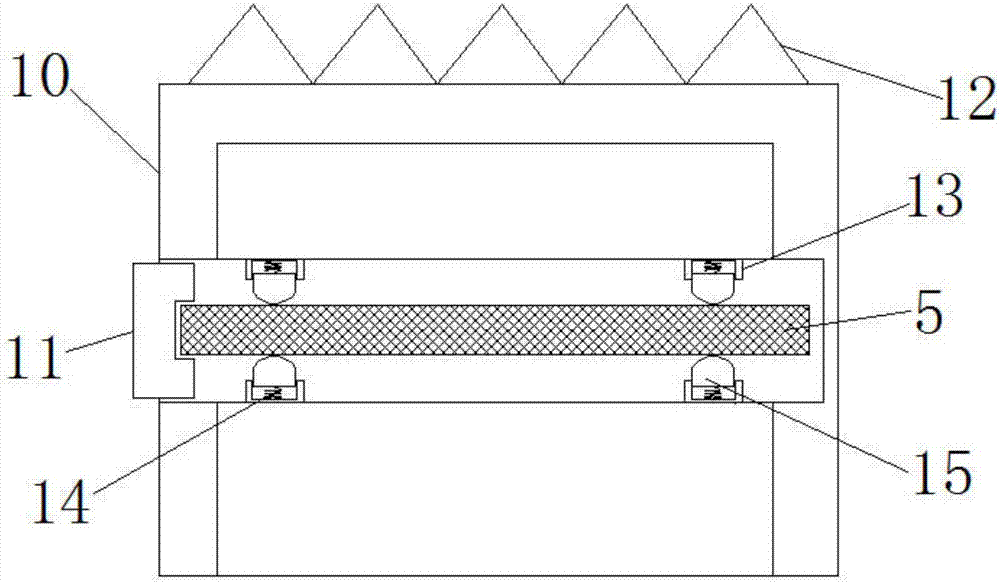

Positioning clamping mechanism in seat cushion sponge production line

The invention discloses a positioning and clamping mechanism in an automobile seat cushion sponge production line, which comprises a transmission device and a fixing frame, and the fixing frame is symmetrically arranged on both sides of the transmission device, and the inner wall of the upper end of the fixing frame is provided with a movable groove. And the movable groove is provided with a rotating shaft, one side of the outer wall of the upper and lower ends of the connecting plate is symmetrically fixedly connected with an L-shaped fixed rod, and the end of the L-shaped fixed rod away from the connecting plate extends to the inner wall of the fixed frame, and the inner wall of the fixed frame A limit slot corresponding to the L-shaped fixed rod is provided. Two symmetrical L-shaped movable rods are vertically inserted into the inner wall of the connecting plate, and one side of the end of the L-shaped movable rod is fixedly connected with a clamping block. A movable shaft is horizontally inserted between the two L-shaped movable rods. The invention has a simple structure and is easy to operate, can effectively position and clamp the sponge product, avoids detachment during the conveying process, and contributes to continuous and stable production.

Owner:德清舒华泡沫座椅有限公司

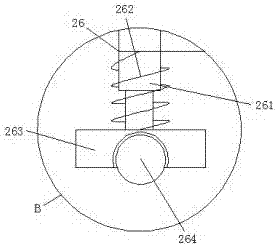

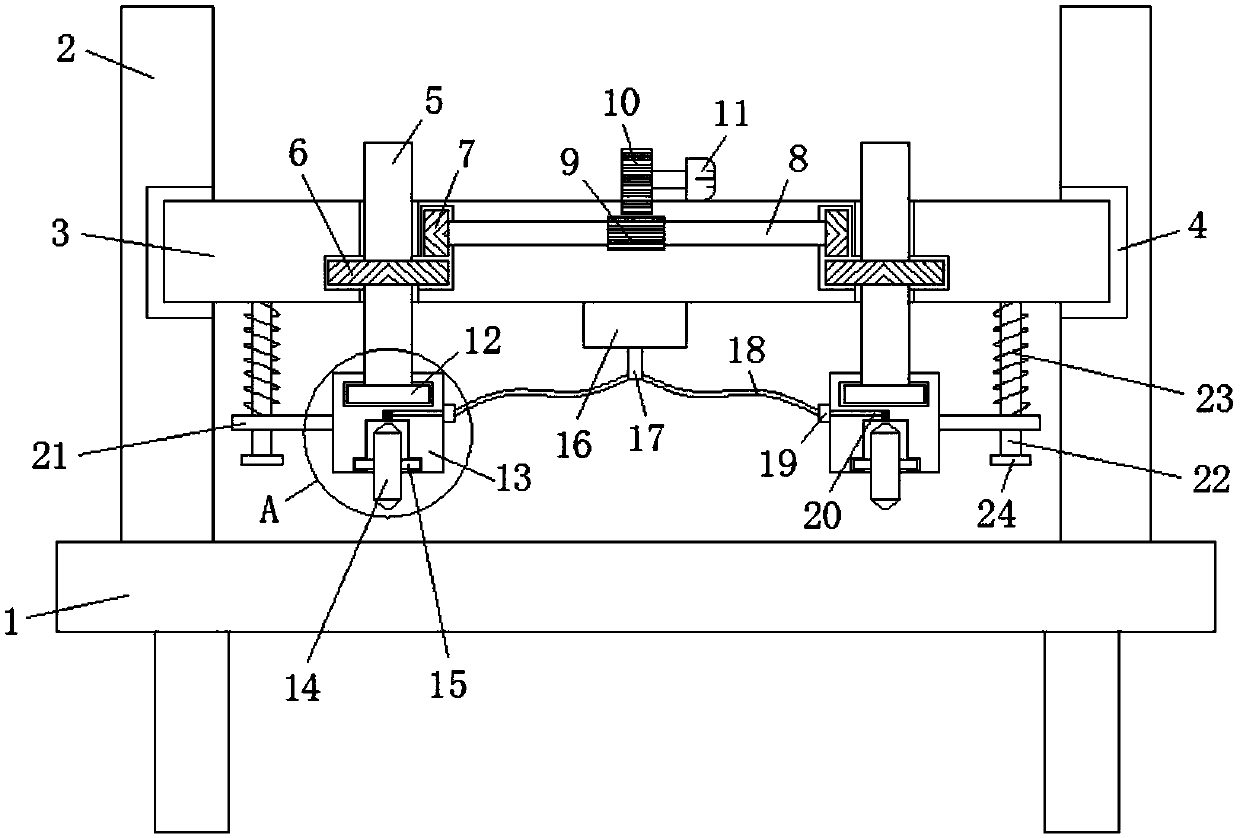

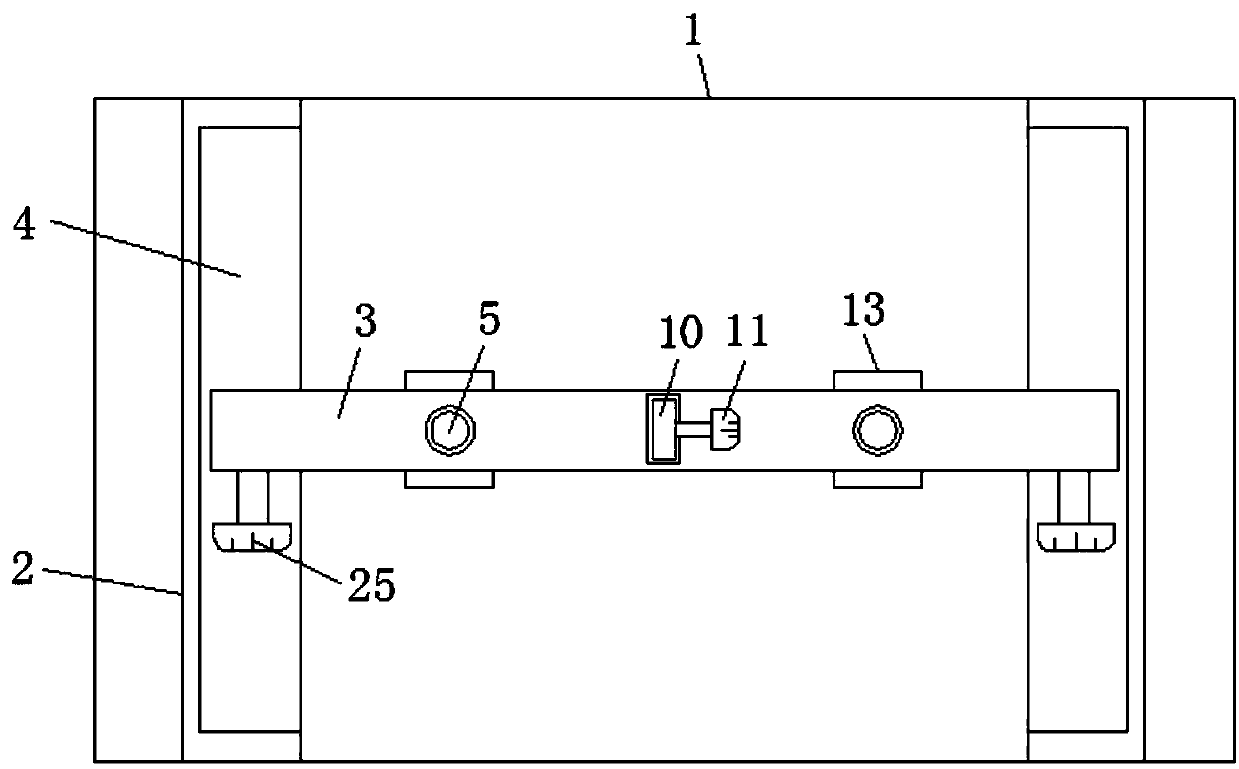

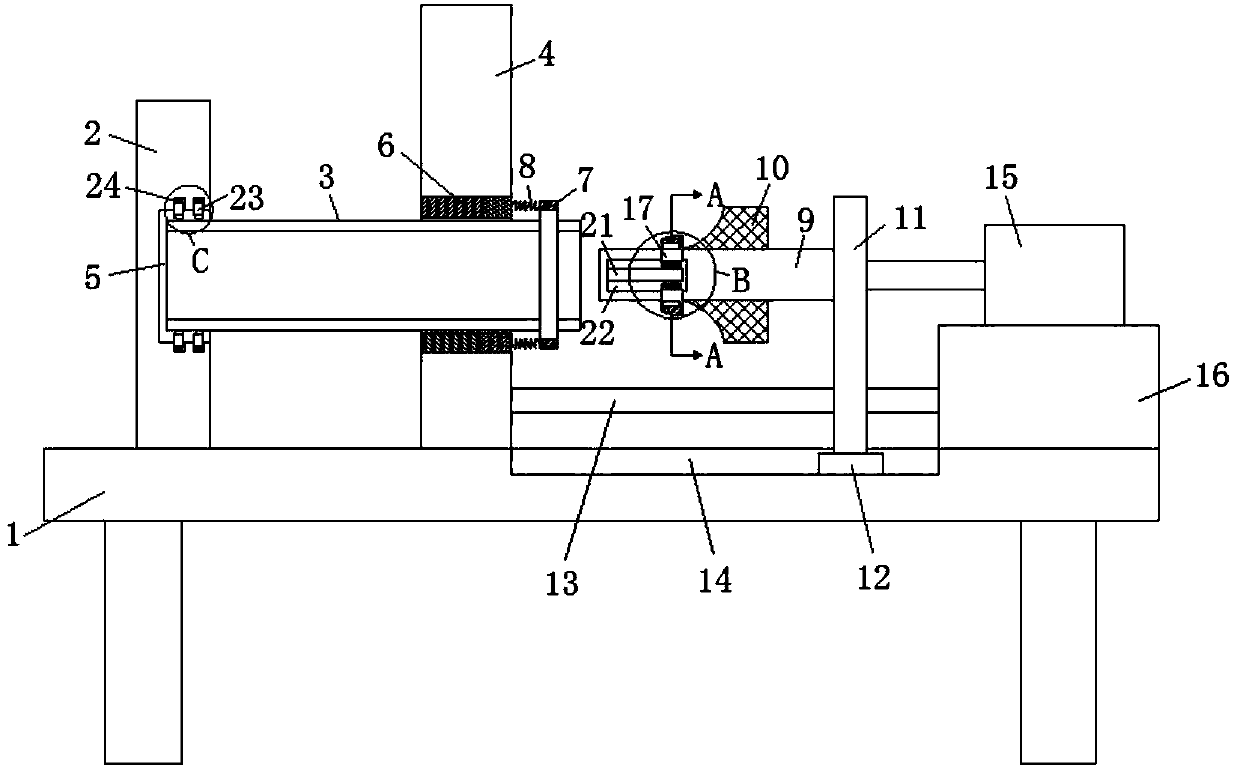

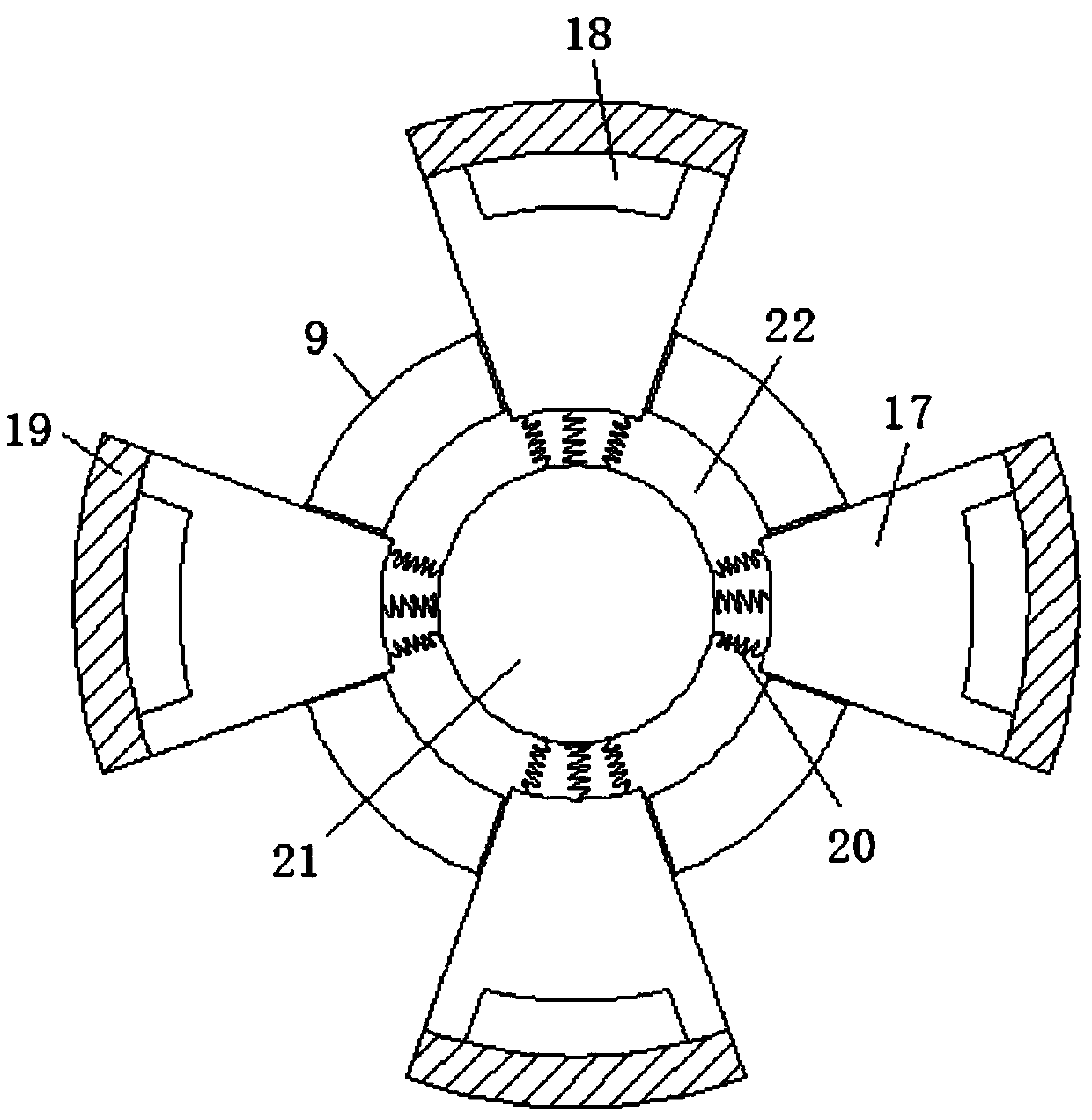

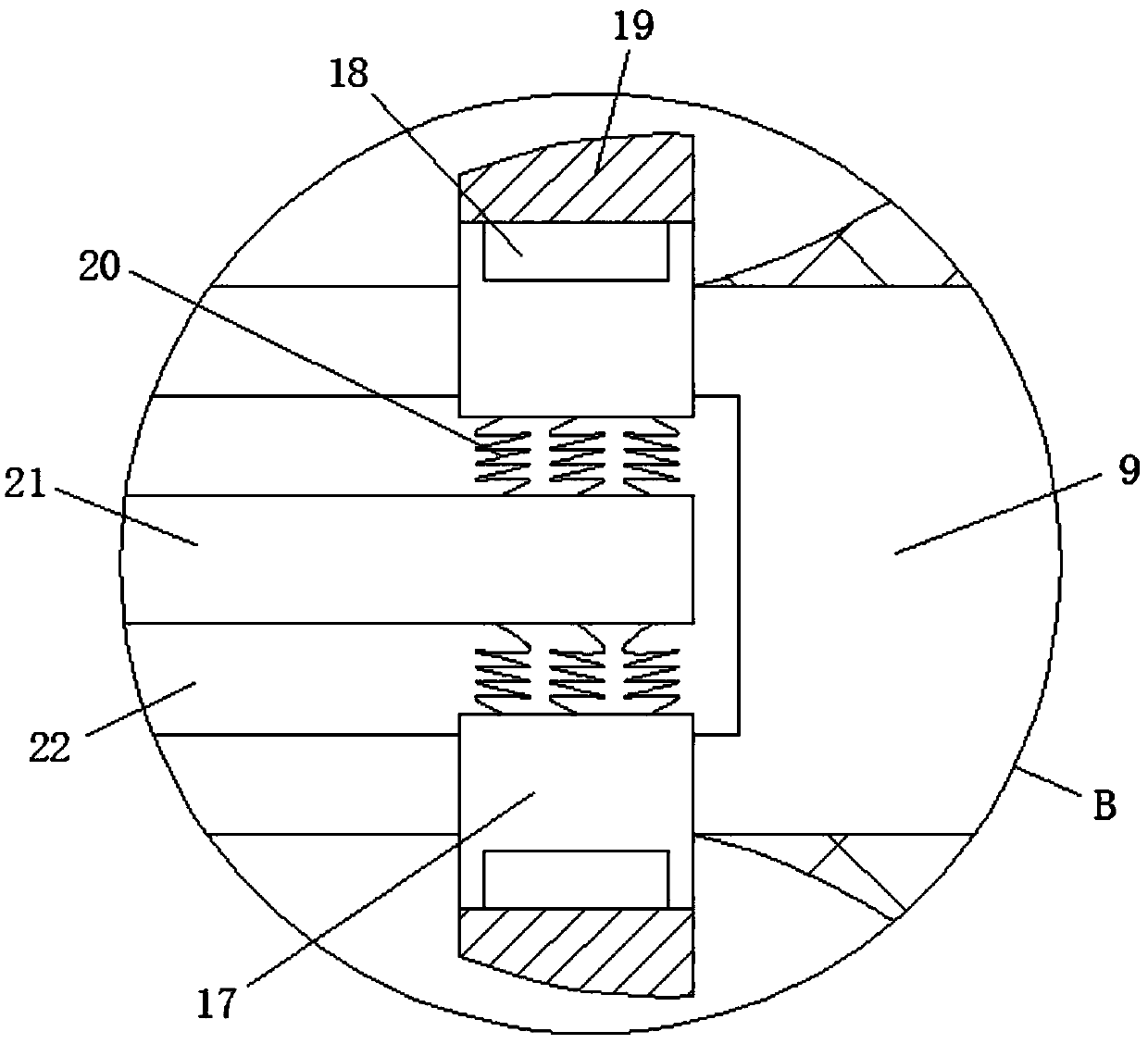

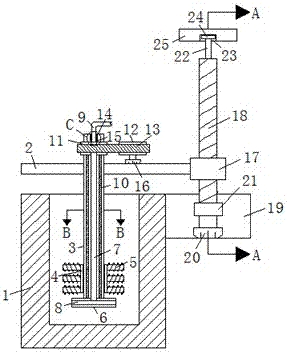

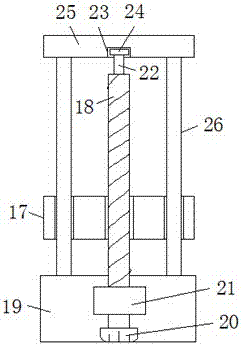

Novel ultrahigh molecular weight polyethylene pipe flanging machine

The invention discloses a novel ultrahigh molecular weight polyethylene pipe flanging machine which comprises a working table, a baffle and a fixed frame. The baffle and the fixed frame are fixed to the upper end of the working table. A pipe is arranged between the baffle and the fixed frame. One end of an air cylinder is connected with a support through a piston rod. One side of the outer wall ofthe support is fixedly connected with a flanging mold. The outer wall of the flanging mold is connected with a flanging convex block in a sleeved manner. An inner cavity is formed in the position, located on the inner wall of the flanging mold, of one side of the flanging convex block. One side of the inner wall of the inner cavity is fixedly connected with a fixed rod. Multiple liner blocks areevenly arranged on the outer wall of the fixed rod through second springs in a surrounding manner, a heat conduction piece is arranged at the outward extending end of each liner block, and an electricheating block is arranged at the position, located in the corresponding liner block, of one side of each heat conduction piece. The novel ultrahigh molecular weight polyethylene pipe flanging machineis simple in structure and easy to operate; automatic flanging of ultrahigh molecular weight polyethylene pipes can be achieved; and meanwhile, operation is stable, work efficiency is high, and laborforce is reduced.

Owner:泰州市兴氟高分子材料有限公司

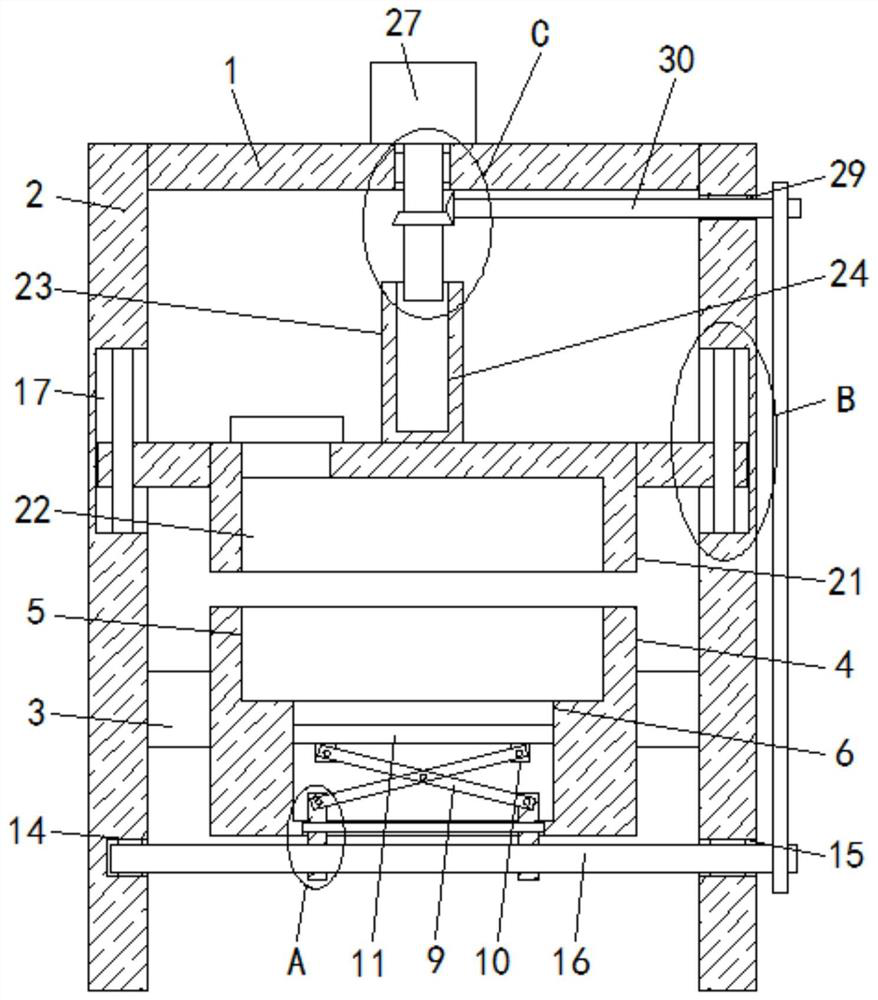

Automatic jacking device of injection mold

The invention relates to the technical field of injection molds, and discloses an automatic jacking device of an injection mold. The automatic jacking device of the injection mold comprises a top board, wherein supporting columns are fixedly installed at both sides of the top board, fixing boards are fixedly installed at both sides, close to each other, of the two supporting columns, a same lowerhalf is fixedly installed at the sides, close to each other, of the two fixing boards, a lower half cavity is formed in the top of the lower half, a sliding groove is formed in an inner wall of the bottom of the lower half cavity, a sealing groove is formed in the bottom of the lower half, the sealing groove communicates with the sliding groove, two sliding boards are slidingly installed in the sealing groove, and rotating boards which are obliquely arranged are rotatably installed on both the sliding boards. The automatic jacking device of the injection mold is simple in structure and convenient to operate, by moving an upper half upwards and downwards, the lower half cavity and an upper half cavity are closed and opened conveniently, through movement of jacking boards, injection moldingparts are jacked, a yield of the injection molding parts is increased, use is convenient and ingenious, the automatic jacking device of the injection mold is suitable for wide popularization, and useeffects are met.

Owner:ANHUI ANLAN MOLD

Simple hand blood circulating instrument

ActiveCN106955188AAchieve pressurizationRealize hot compressRoller massageTherapeutic coolingHand partsEngineering

The invention discloses a simple hand blood circulating instrument. The instrument comprises a first box body and a cover plate, wherein rotating blocks are symmetrically arranged at two sides of the lower end of the cover plate; the first box body is connected with the cover plate through a rotating block hinge; a second box body is arranged at the side, facing the first box body, of the cover plate; a rubber cushion, a silicon gel cushion and an elastic rubber film are sequentially arranged between the first box body and the second box body from the bottom surface to openings. With the adoption of the instrument, a patient can independently perform centric massaging on hands; the instrument is simple in structure, and easy to operate.

Owner:PEKING UNIV THIRD HOSPITAL

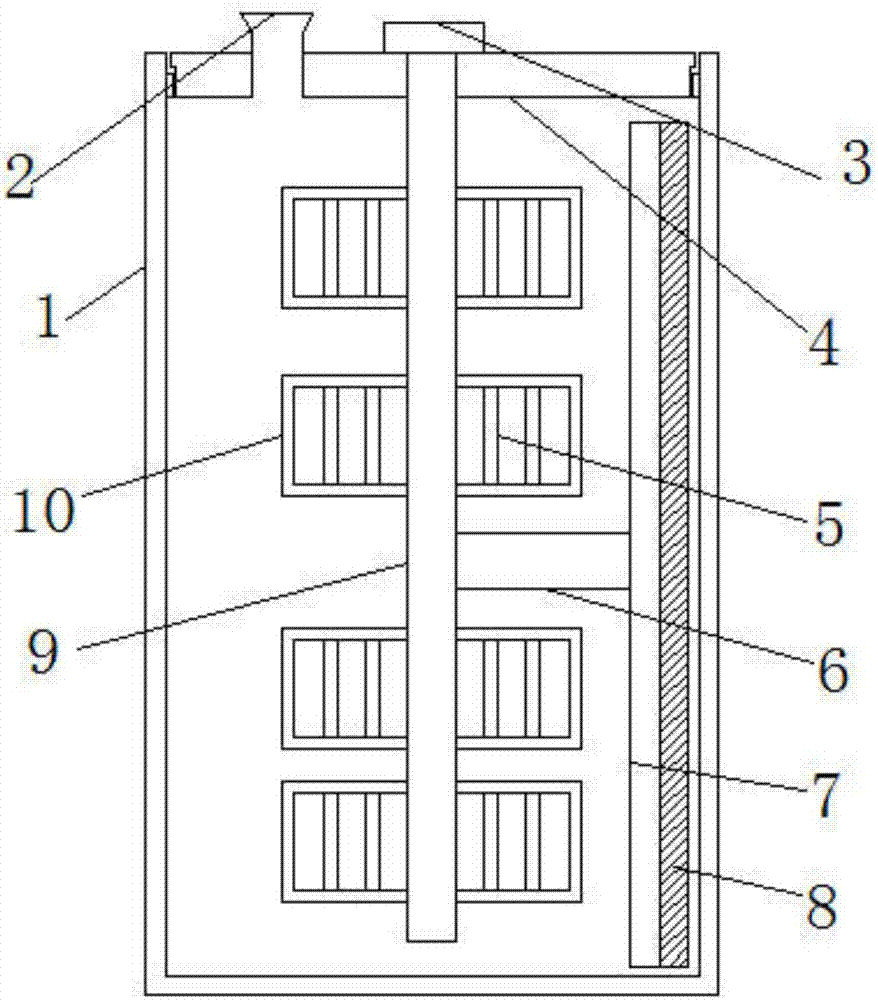

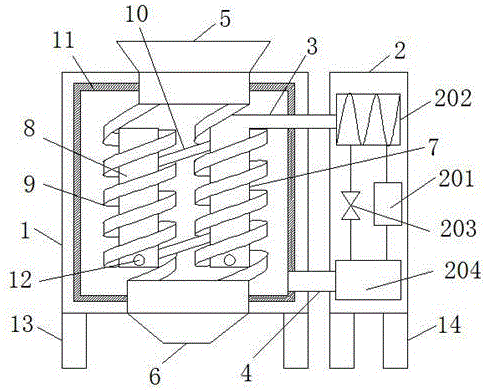

Air energy drying machine for Chinese herbal medicines

InactiveCN106482465AImprove stabilityImprove drying effectDrying gas arrangementsDrying machines with local agitationEngineeringEvaporator

The invention discloses an air energy drying machine for Chinese herbal medicines. The air energy drying machine comprises a machine shell and support legs, wherein a drying box and a running chamber are arranged in the machine shell; a separating plate is arranged between the drying box and the running chamber; a box door is arranged on one side of an outer wall of the drying box; a control center is arranged on one side of the outer wall of the running chamber; a drying device is arranged in the running chamber; the drying device is composed of a compressor, a condenser, a throttling device and an evaporator; a suction fan is arranged on one side of the bottom of the running chamber; a dehumidifying port is arranged at one end of the suction fan; the interior of the machine shell is divided into the drying box and the running chamber by the separating plate; a plurality of mounting racks are arranged in the drying box; the mounting racks are equidistantly and vertically distributed on one side of the inner wall of the drying box. The air energy drying machine for Chinese herbal medicines has the advantages of simple structure, easiness in operation, better effect of drying the Chinese herbal medicines, more clean and hygienic effect, convenience and smartness in use and suitability for wide popularization.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

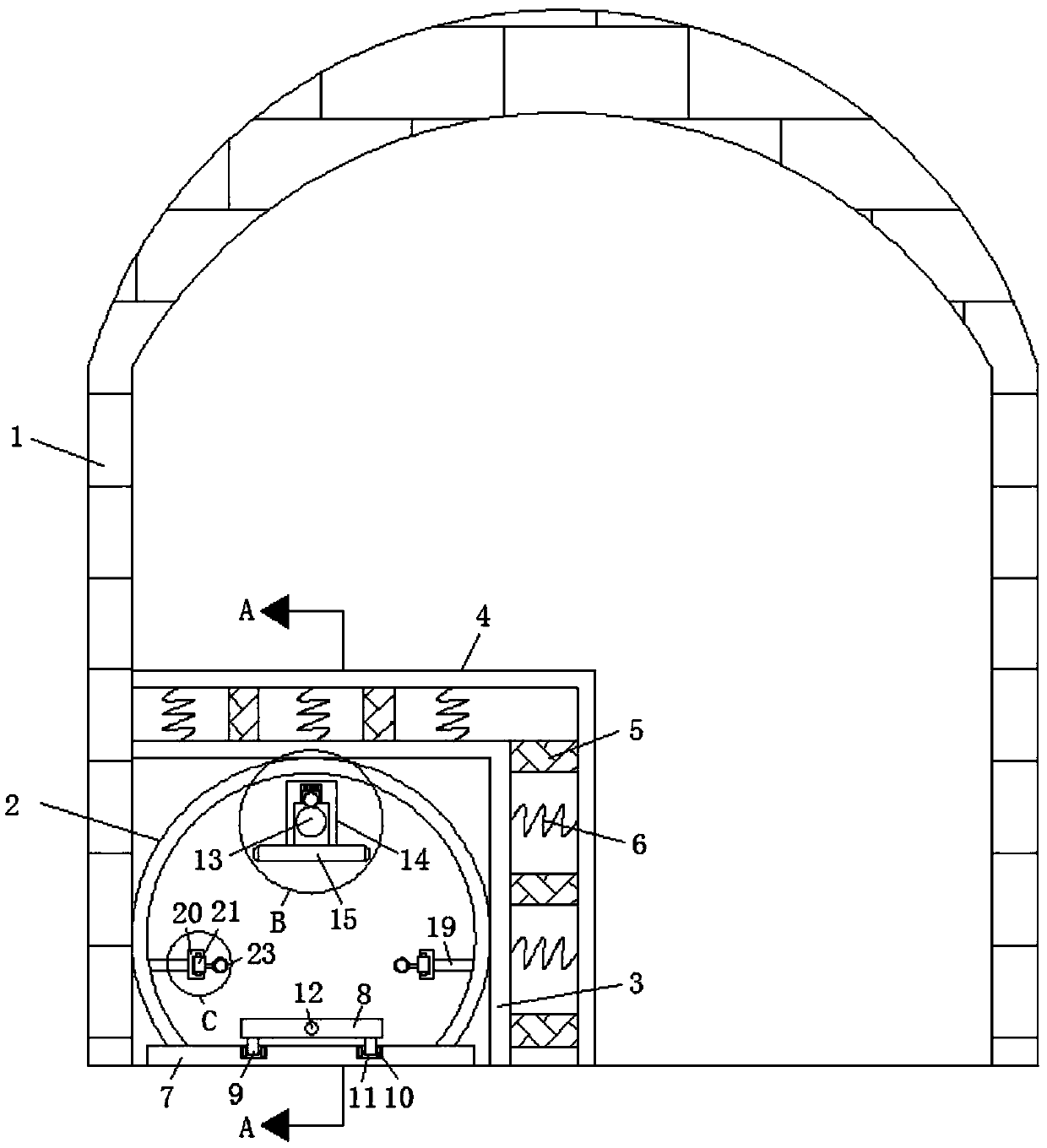

Impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline

The invention discloses an impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline. The impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline comprises a tunnel and an escape pipeline body; the escape pipeline body is fixed to one side of the ground plane inside the tunnel; a flat bottom plate is arranged at the bottom of theescape pipeline body, and an escape sliding plate is arranged at the upper end of the flat bottom plate; supports are fixedly connected to the periphery of the lower end of the escape sliding plate, and sliding wheels are arranged at the bottoms of the supports; an escape rope is arranged in the escape pipeline body, and the two ends of the escape rope are fixed to the two ends of the escape pipeline body through fixing pieces; a fixing frame is connected to the outer wall of the escape rope in a sleeving mode, and the bottom of the fixing frame is fixedly connected with a handle; a limiting block is arranged on the inner wall of the upper end of the fixing frame through a limiting groove, and a ball is arranged at the lower end of the limiting block; a first L-shaped protection plate anda second L-shaped protection plate are arranged outside the escape pipeline in sequence from inside to outside. The impact-resistant flat bottom type ultra-high molecular weight polyethylene escape pipeline is simple in structure, easy to operate, small in weight, convenient to mount and meanwhile capable of increasing the escape probability of escape personnel.

Owner:泰州市兴氟高分子材料有限公司

Dust collection device specially used for ceramic production

InactiveCN107224778AImprove sealingSimple structureCleaning using liquidsFiltration circuitsEngineeringPrecipitation

Owner:CHONGQING YONGHENG BOTAO TECH

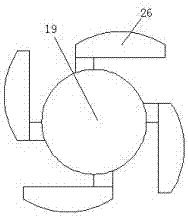

Iron removing pug mill for ceramic production

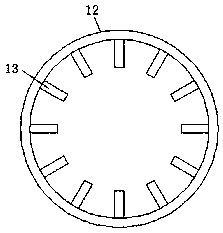

InactiveCN107225678AAvoid displacementClean evenlyHollow article cleaningClay processing apparatusAgricultural engineeringDrive motor

The invention discloses an iron-removing mud mill for ceramic production, which comprises a box shell, a cover plate is threadedly connected to the annular notch, a feeding pipe is penetrated through the cover plate, and the middle part of the upper end of the cover plate is provided with a cover plate. There is a driving motor, the driving end of the driving motor is provided with a stirring shaft, and a plurality of stirring blades are vertically distributed on the stirring shaft, each of the stirring blades is provided with a plurality of first grooves, each of the stirring blades A magnetic rod is interspersed in the first groove, two fixed blocks are symmetrically arranged on both sides of each said magnetic rod, and a locking cover is threadedly connected to the opening of each said first groove, and the middle part of said stirring shaft A connecting rod perpendicular to it is provided, and the end of the connecting rod away from the stirring shaft is provided with a fixed rod perpendicular to the connecting rod, and a layer of brushes is uniformly arranged on the fixed rod. The invention has a simple structure and realizes the functions of efficient iron removal from ceramic soil and easy cleaning of iron filings. The device is convenient and ingenious in use and is suitable for wide popularization.

Owner:CHONGQING YAYU CERAMICS CO LTD

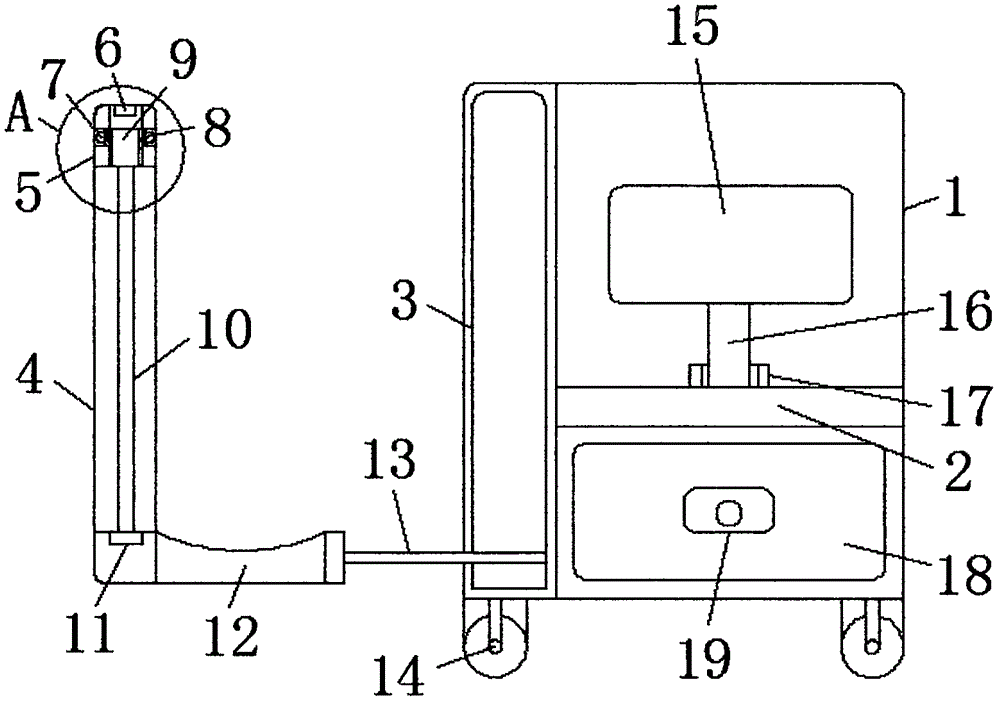

Rigid multi-channel 3D (three-dimensional) anoscope system

InactiveCN106798541AEasy to storeIncrease frictionEndoscopesRectum colonoscopesEngineeringStorage tank

The invention discloses a rigid multi-channel 3D anoscope system. The rigid multi-channel 3D anoscope system comprises a machine housing and a sleeve; a connecting wire is arranged between the machine housing and the sleeve; the circumference of the lower end of the machine housing is provided with wheels; the upper end of a base is provided with a support frame, and one end of the support frame, which is away from the base, is provided with a display screen; one side of the inside of the machine housing is provided with a storage tank, and one side of the inner wall of the lower end of the storage tank is connected with the connecting wire; one end of a handle, which is away from the connecting wire, is provided with the sleeve; one end of the sleeve, which is away from the handle, is provided with an anoscope probe; the outside of a connecting shaft is provided with a ring-shaped fastening block in a sleeving mode; a plurality of cameras are uniformly arranged around the outer wall of the ring-shaped fastening block; the top center of the anoscope probe is provided with a main camera. The rigid multi-channel 3D anoscope system is simple in structure, convenient to operate, capable of achieving three-dimensional imaging effects to further reduce surgical difficulty and to improve the surgical safety factors, rapid and skillful in utilization and applicable to wide popularization.

Owner:娄爱华

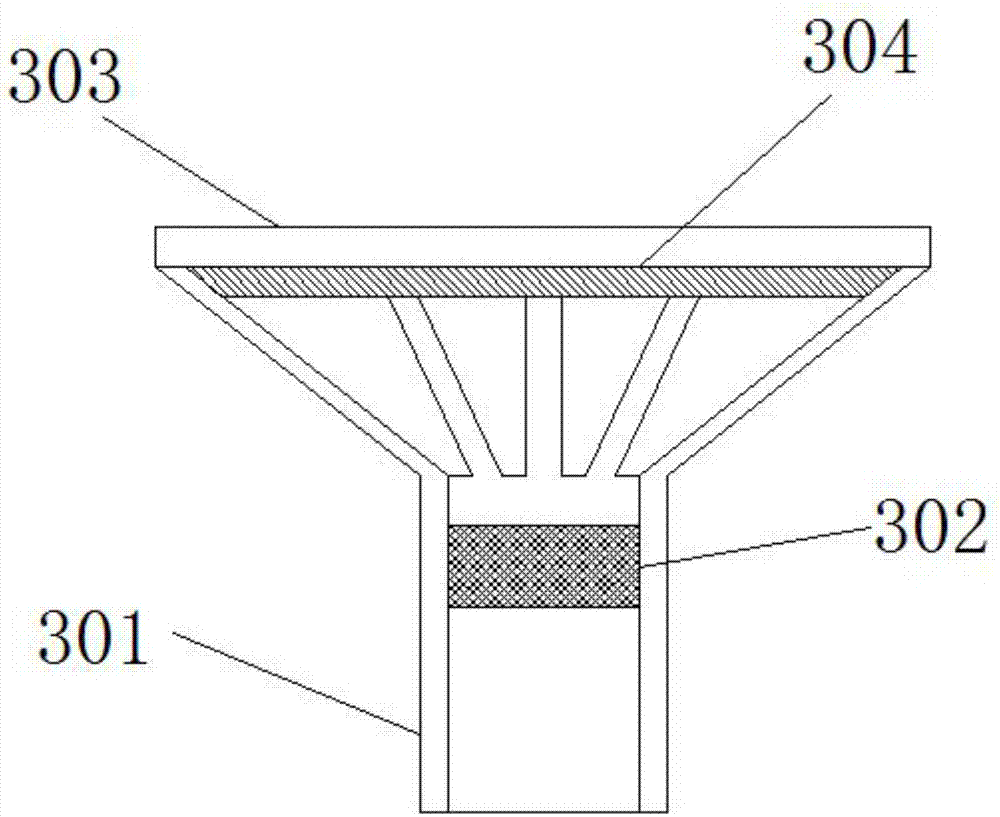

Aluminum water mixing and degassing device for mechanical casting

The invention discloses an aluminum water mixing and degassing device for mechanical casting. The device comprises a casting furnace and a fixing seat, wherein the fixing seat is fixedly arranged on one side of the outer wall of the upper end of the casting furnace, a graphite connecting rod is inserted in the casting furnace, the outer wall of the end, extending outwards, of the graphite connecting rod is sheathed with a supporting plate, the outer wall of the lower end of the graphite connecting rod is connected with an annular clamping block in a threading manner, a plurality of groups of screw shafts are uniformly arranged at the outer wall of the annular clamping block in a surrounding manner, a breather pipe is arranged in the inner wall of the graphite connecting rod in a penetrating manner, a plurality of shunting pipes are communicated with the end, extending into a bottom support, of the breather pipe, an air inlet pipe is inserted into the inner wall of one end, far away from the shunting pipes, of the breather pipe, one end of the supporting plate is fixedly connected with a movable block, a screw rod is inserted in the middle of the movable block, and the screw rod is in threaded connection with the movable block. The device has the advantages of being simple in structure, easy to operate, and capable of fully mixing aluminum water in the casting furnace so as to purify the aluminum water and improve the quality of castings.

Owner:CHONGQING JIANTAO ALUMINUM

Air exhausting device for mechanical casting die

InactiveCN107363222AIntegrity guaranteedSolve air hole quality problemsFoundry mouldsFoundry coresEngineeringPulp and paper industry

The invention discloses an exhaust device for a mechanical casting mold, which comprises a mold and an exhaust cover. The center of the upper end of the mold is communicated with a pouring port, and both sides of the upper end of the mold are symmetrically communicated with exhaust channels, and the exhaust The upper end of the channel is provided with an exhaust hood, the outer wall of the exhaust hood is fixedly connected with fixed blocks symmetrically on both sides, and the lower end of the fixed block is fixedly connected with a support rod, and the support rod is fixed on the upper end of the mold. A sealing plug is provided, and the upper end of the sealing plug is fixedly connected with a top cover. The end of the first telescopic rod extending into the exhaust passage is provided with a piston block, and the outer wall of the piston block is sleeved with two symmetrical sealing rings. A connecting shaft is provided at the end of the second telescopic rod extending inwardly through the top wall of the exhaust hood. The invention is simple in structure and easy to operate, can effectively dissipate heat and exhaust air during mechanical casting, ensures the integrity of the appearance of castings, and improves the quality and efficiency of products.

Owner:湖州永盛机械铸造有限公司

Novel air-source dryer for powder food processing

InactiveCN106482491AImprove drying effectImprove drying efficiencyDrying gas arrangementsDryingEngineering

The present invention discloses a novel air-source dryer for powder food processing. The novel air-source dryer comprises a drying box and a box body. A feeding funnel is disposed on an upper end of the drying box. A feed hopper is disposed on an upper end of the drying box. Feed inlets are symmetrically disposed at two sides of an extension end of the feed hopper, and both connected with spiral material pipes. The ends, far away from the feed inlets, of the two spiral material pipes are connected with a discharge pipe. The two spiral material pipes surround a first drying cylinder and a second drying cylinder, respectively. A plurality of vent pipes are connected between the first drying cylinder and the second drying cylinder. An upper end of the first drying cylinder communicates with a blast pipe, and the end, far away from the first drying cylinder, of the blast pipe extends into the box body. A compressor, a condenser, a throttling device and an evaporator are disposed in the box body. The end, extending into the box body, of the blast pipe communicates with the condenser. The novel air-source dryer for powder food processing is simple in structure, easy to operate, good in powder food drying effect, and not prone to accumulation; and the device is convenient and smart in use, and suitable for extensive promotion.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

Air conditioner indoor hanging unit panel

InactiveCN107062576AAvoid discomfortImprove the decorative effectMechanical apparatusSpace heating and ventilation safety systemsCold airEngineering

The invention discloses an indoor hanging panel of an air conditioner, comprising a body shell, a display screen is arranged on one side of the outer wall of the body shell, a plurality of LED lamp beads are evenly arranged on the edge of one side of the outer wall of the body shell, and the body shell is A first drive device is symmetrically arranged on both sides of the two first drive devices, one end of the two first drive devices is provided with a connecting shaft, and one end of the two connecting shafts away from the first drive device is provided with a first rotating shaft. One end of the first rotating shaft is provided with a second driving device, and a wind deflector is arranged between the two first rotating shafts. The two sides of the wind deflector are symmetrically provided with a bottom plate, and each second rotating shaft is far away from the sliding shaft. One end of the block is provided with a third driving device, and one side of each two sliding blocks is fixedly connected with a cover plate. The present invention is simple in structure and easy to operate, and the direct blowing of cold air from the air conditioner is avoided through the air guide plate, and the discomfort of the human body is alleviated.

Owner:黄科钧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com