Cleaning method of reaction chamber

A reaction chamber and cleaning gas technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problem of pressure control valves not working properly, reaction chamber cleaning is not clean, pipelines Blockage and other problems, to improve the cleaning effect, improve the yield rate of the product, and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

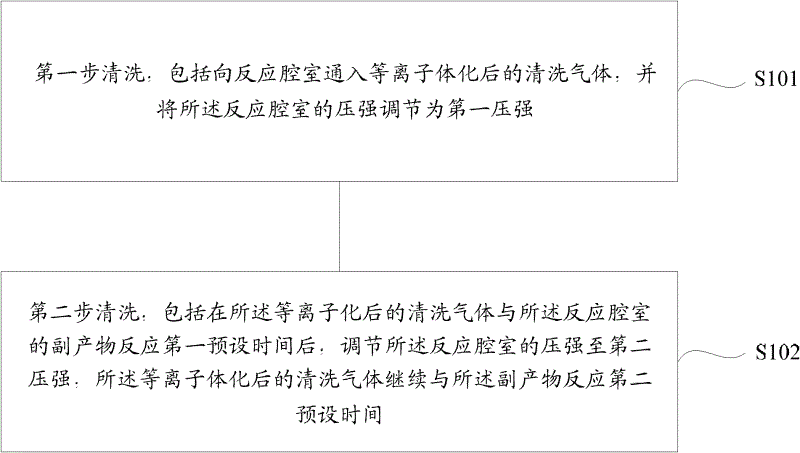

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, due to the method of depositing SiO using TEOS and ozone or oxygen 2 as an example, so its by-product is usually SiO 2 , for SiO 2 For cleaning, the cleaning gas generally used is a mixed gas of fluorine-containing gas and oxygen, wherein the fluorine-containing gas is hexafluoroethane (C 2 f 6 ), CF 4 , nitrogen trifluoride (NF 3 )one of a kind. for C 2 f 6 、CF 4 In terms of C 2 f 6 or CF 4 gas, while using radio frequency source or high frequency source to C 2 f 6 or CF 4 Plasma, while for NF 3 In other words, the NF is first passed through the plasma generator 3 Plasma, then NF 3 The plasma is directly passed into the reaction chamber.

[0037] In this example, C 2 f 6 As an example, the purge gas is C 2 f 6 and O 2 The mixed gas is passed into the reaction chamber, and at the same time, the C 2 f 6 and O 2 The mixed gas plasma, described in this example C 2 f 6 The flow rate is 2000 sccm to 3000 sccm, for example: 2000 ...

Embodiment 2

[0047] In this embodiment, SiO is still deposited by using TEOS and ozone or oxygen 2 As an example, the difference is that the pressure control valve in this embodiment is a pressure control valve with a fan blade structure, which controls the pressure of the reaction chamber through the opening angle of the fan blade. For the pressure control valve with fan blade structure, as the thickness of the deposited film layer in the reaction chamber increases, the fan blade will also be covered with a thick layer of by-products (usually SiO 2 ).

[0048] In the present embodiment, the first step of cleaning is similar to that in Example one, C 2 f 6 The flow rate is 2000sccm~3000sccm, O 2 The flow rate is 3000sccm ~ 4500sccm, the first pressure is 2Torr ~ 10Torr, that is, those skilled in the art can according to the C in the cleaning gas 2 f 6 and O 2 The flow range and the range of the first pressure to choose C 2 f 6 and O 2 The flow rate and the first pressure value, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com