Immersed type on-line cleaning method and device for slab ceramic membrane

A cleaning device and ceramic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor cleaning effect, long cleaning time, time-consuming and laborious, etc., and achieve simple structure and floor space. Less, improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

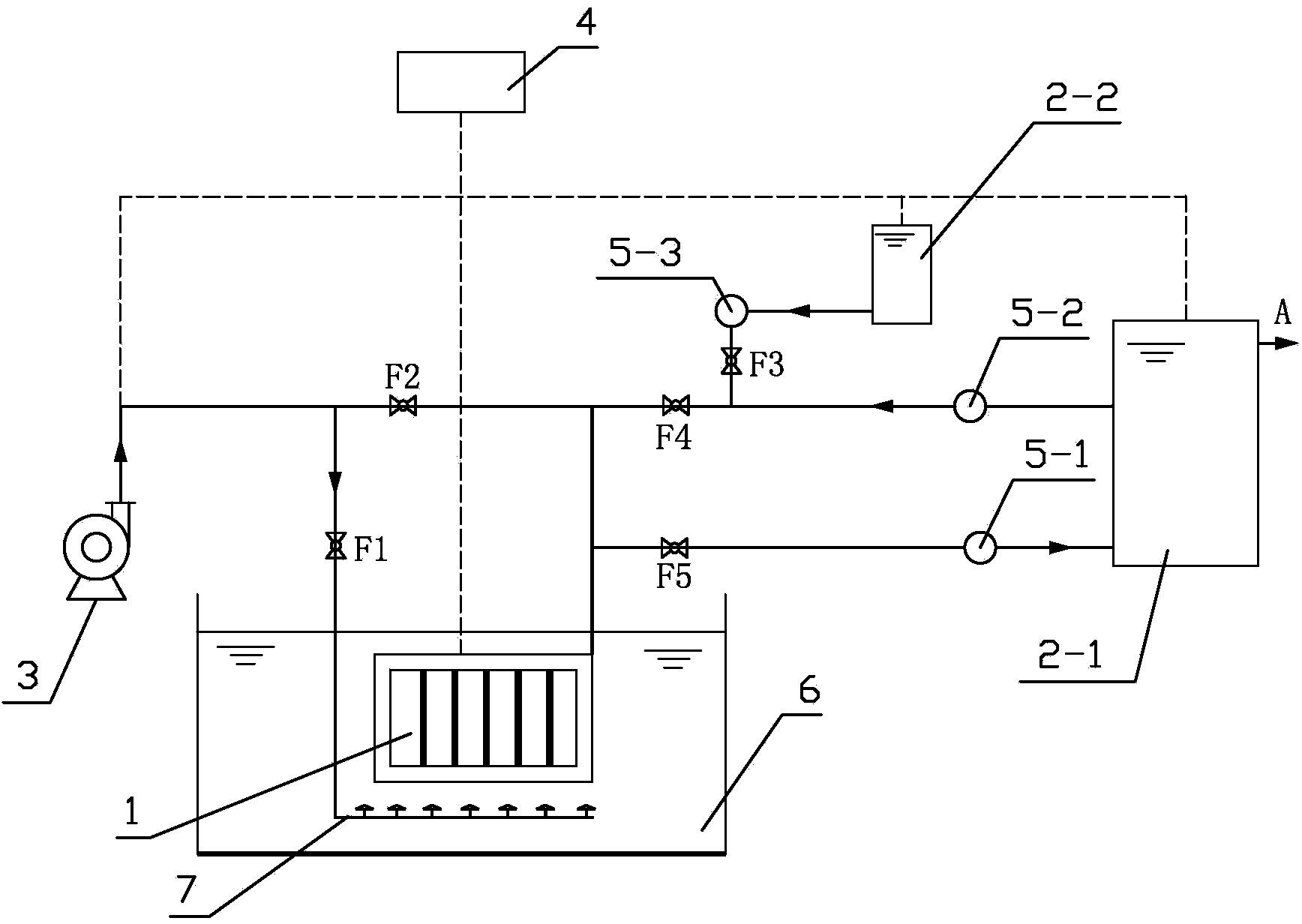

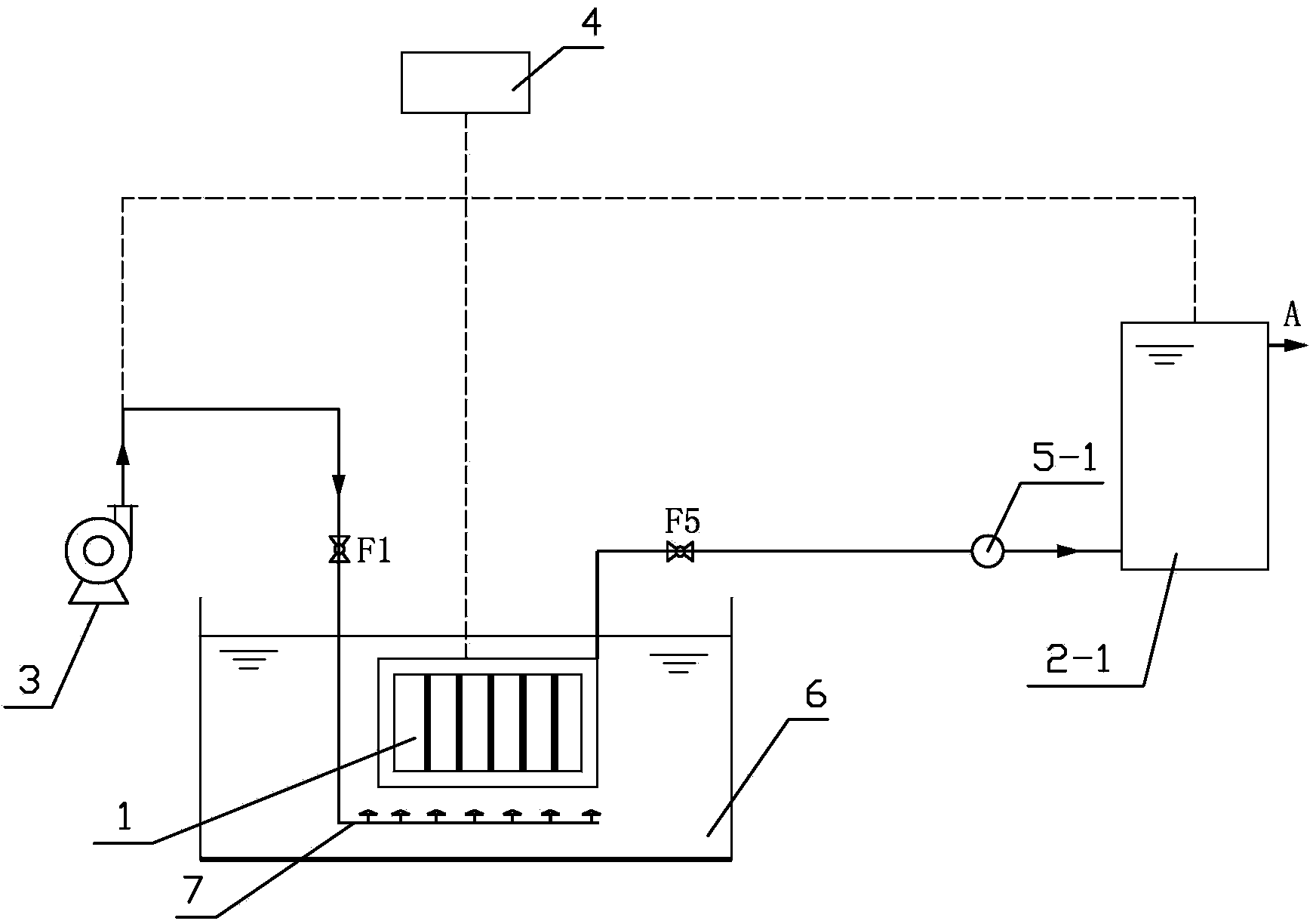

Embodiment 1

[0052] A sewage treatment plant adopts submerged flat ceramic membrane MBR process (membrane bioreactor) for wastewater treatment, and adopts online cleaning process for membrane cleaning. The system includes automatic control system, liquid reverse flushing system and gas-liquid combined backwashing system; The automatic control system monitors the transmembrane pressure of the ceramic membrane in real time through the pressure transmitter. When the transmembrane pressure difference is greater than 0.04MPa, the automatic control system closes the outlet valve of the flat ceramic membrane module, opens the liquid reverse flushing valve F4, and starts the backwash pump 5-2 and cleaning agent metering pump 5-3, the backwash pressure is 0.3MPa, and the flushing time is 2 minutes; then the Roots blower and gas reverse flushing valve F2 are turned on, the gas reverse flushing pressure is 0.4MPa, and the gas-liquid combined backflush time is 2 minutes, and then automatically Close th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com