Paper pushing mechanism for corrugated paper production

A corrugated paper and aligning board technology, which is applied in the field of corrugated paper manufacturing, can solve the problems of affecting the placement of corrugated paper, the corrugated paper is squeezed, and the operation method is complicated, and achieves the effects of stable vibration effect, good connection strength, and wide vibration area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

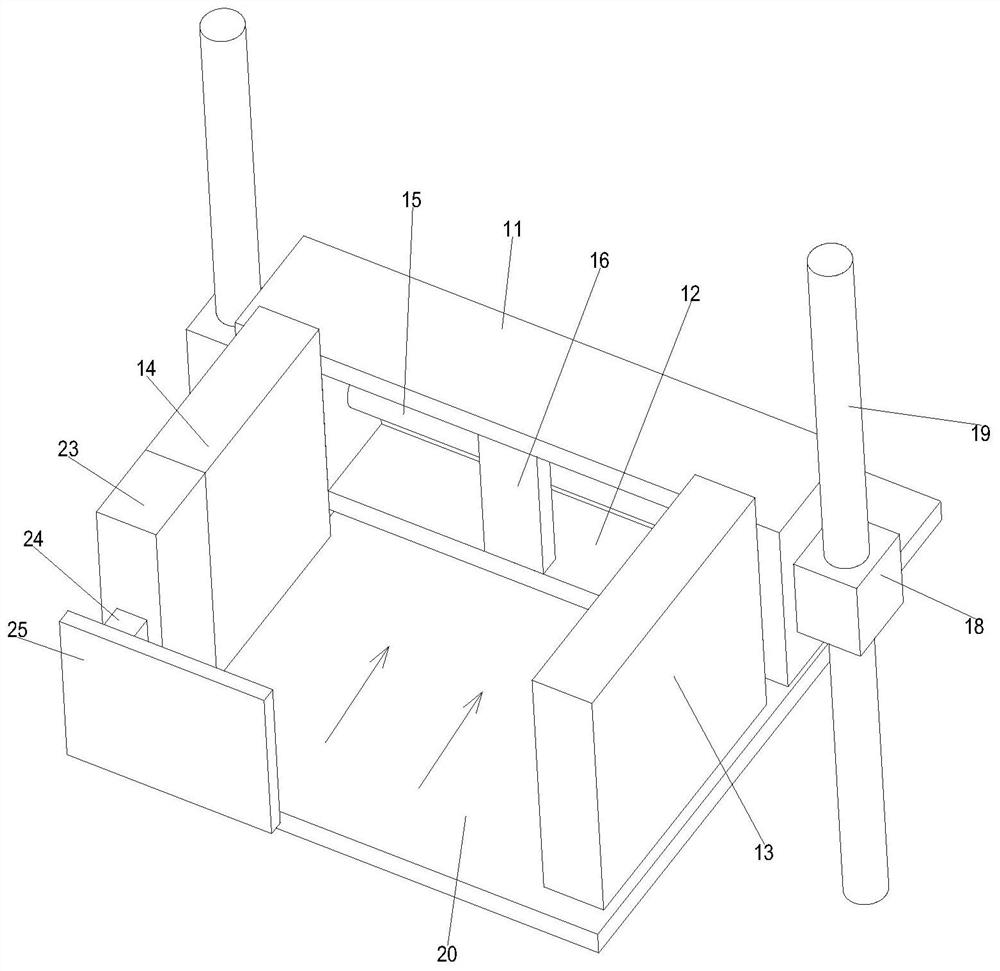

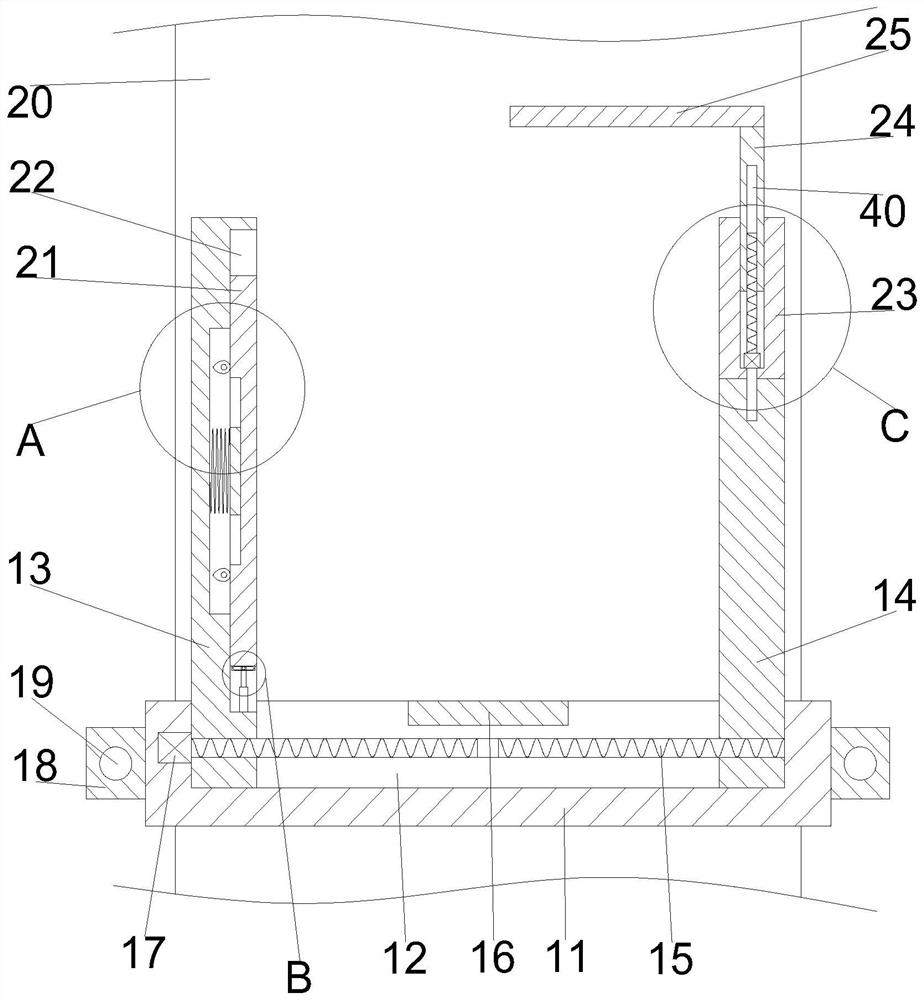

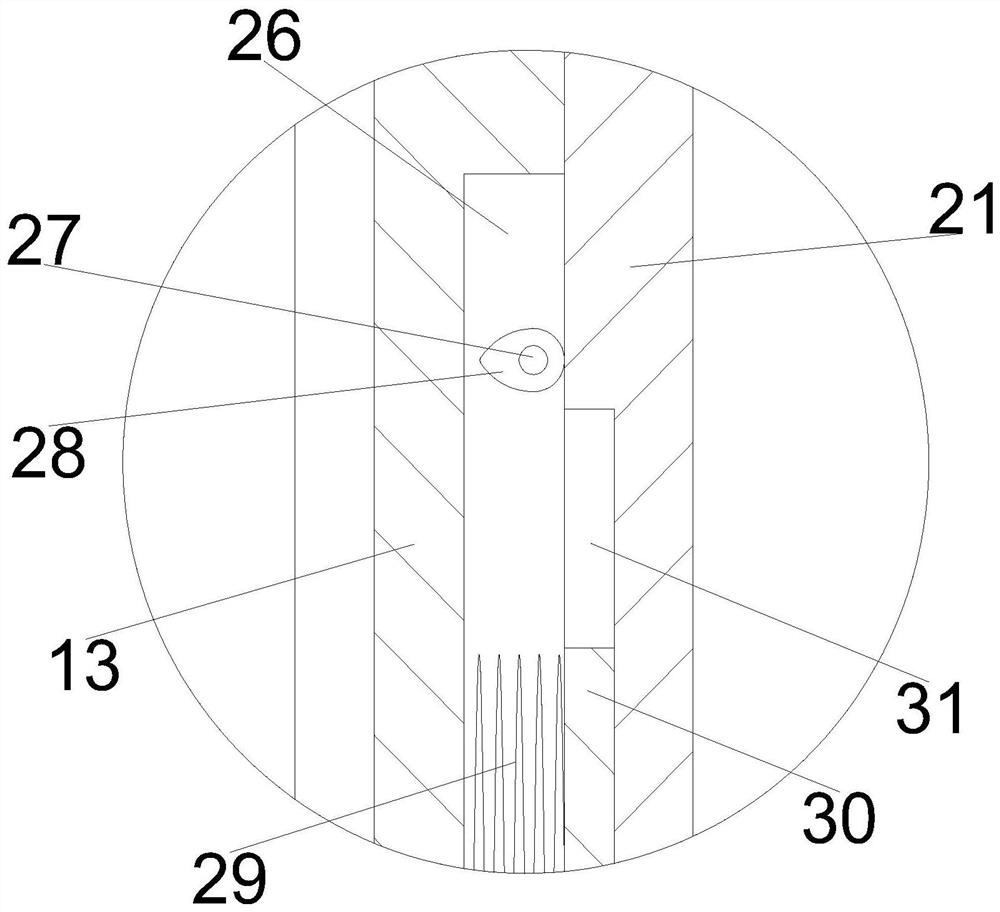

[0028] Specific embodiment one: please refer to Figure 1-5 A paper pushing mechanism for corrugated paper production, comprising a moving seat 11, a first aligning plate 13, a second aligning plate 14, a rotating block 23, a sliding bar 24, a front side baffle 25 and an aligning device;

[0029] The corrugated paper to be aligned is located between the first aligning plate 13 and the second aligning plate 14, the aligning device is arranged in the first aligning plate 13, the aligning device is provided with a vibrating element and a sliding adapting element, the vibrating element Vibration can be generated to align the corrugated paper to be aligned between the first alignment plate 13 and the second alignment plate 14. The sliding adaptation element can make the vibration element slide while vibrating, thereby increasing the vibration of the vibration element. Vibration range;

[0030] The first alignment plate 13 is slidably connected with the moving seat 11, the second a...

specific Embodiment 2

[0039] Specific embodiment 2: On the basis of specific embodiment 1, the external power and control system closes the drive device, and then makes the conveyor belt 20 in the non-transmission state, and starts the screw devices on both sides through the external power and control system, and then drives both sides to lift The screw rod 19 rotates, and the screw rods 19 on both sides are threadedly connected with the connecting blocks 18 on both sides, thereby driving the moving seat 11 to move downward, and the downward movement of the moving seat 11 drives the first alignment plate 13 to align with the second alignment block. The bottom of the plate 14 is close to the top of the conveyor belt 20, and the bidirectional motor 37 is activated by the external power and control system, and the bidirectional motor 37 drives the rear output shaft to rotate, thereby driving the rotating shaft 39 to rotate, and the rotating shaft 39 is aligned with the second alignment. The fixed conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com