Anti-blocking and flying-dust-free type cement transfer tank for highway construction site

A construction site and anti-clogging technology, which is applied in the field of dust-free cement transfer tanks and anti-clogging on highway construction sites, can solve the problems of easily generating dust, affecting the transportation efficiency of cement tankers, and easily adsorbing water vapor and hardening, and achieving the vibration effect. Good, convenient and fast feeding and unloading, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

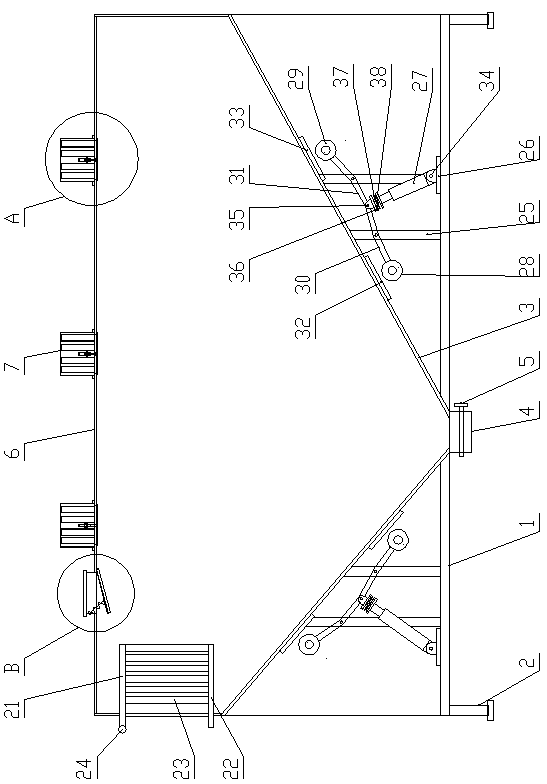

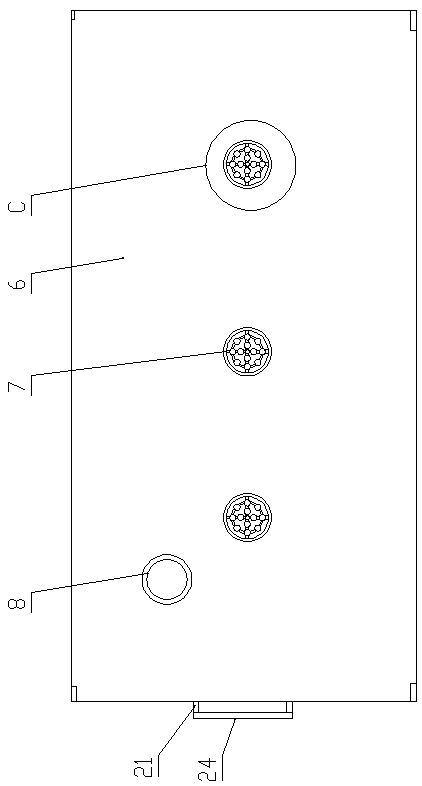

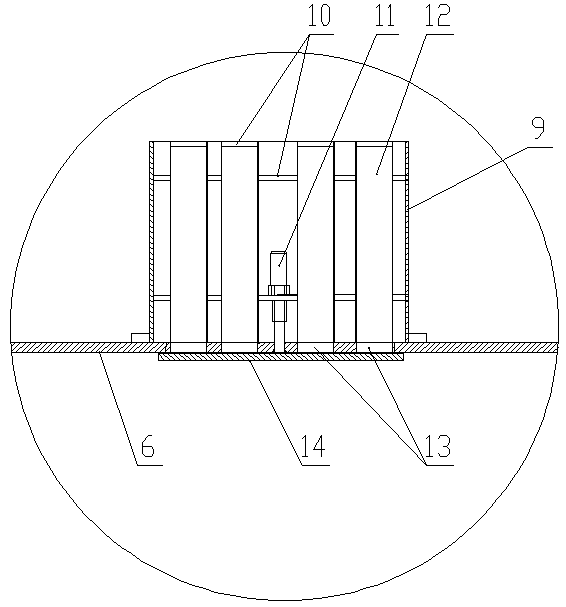

[0023] Such as Figure 1-Figure 5 As shown, the anti-clogging and dust-free cement transfer tank for road construction site of the present invention includes a container 1 in the shape of a cuboid, a leg 2 is respectively arranged at the four corners of the bottom of the container 1, and a tank body 3 is arranged in the container 1. The lower part of the tank body 3 has a conical structure with a large top and a small bottom. The lower end of the tank body 3 is provided with a discharge port 4 protruding from the bottom of the container 1, and a discharge valve 5 is provided at the discharge port 4; the top of the container 1 is provided with a valve for sealing The top cover 6 of the tank body 3 is provided with a feed port and a feed exhaust device 7 on the top cover 6, an automatic feed sealing device 8 is provided at the feed port, and a discharge booster mechanism is provided on the upper side of the container 1; Between the bottom of the container 1 and the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com