Sound insulation cotton with multi-layer sound absorbing materials and compressor

A technology of sound-absorbing materials and sound-insulating cotton, which is applied in the fields of noise suppression, mechanical equipment, machines/engines, etc., can solve the problem of low radiation noise of sound-insulating cotton, and achieve the effect of facilitating absorption, wide source of materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

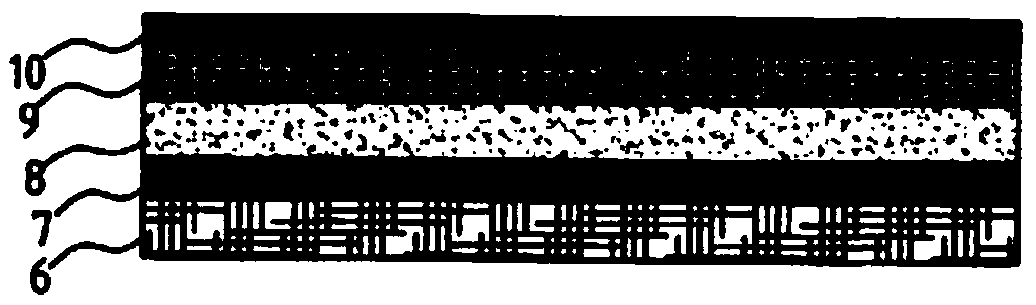

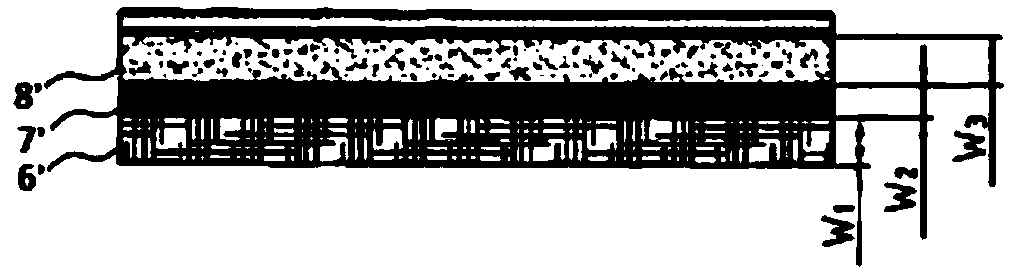

[0028] This embodiment relates to a compressor, and the outside of the compressor is covered with sound-insulating cotton laminated with various sound-absorbing materials.

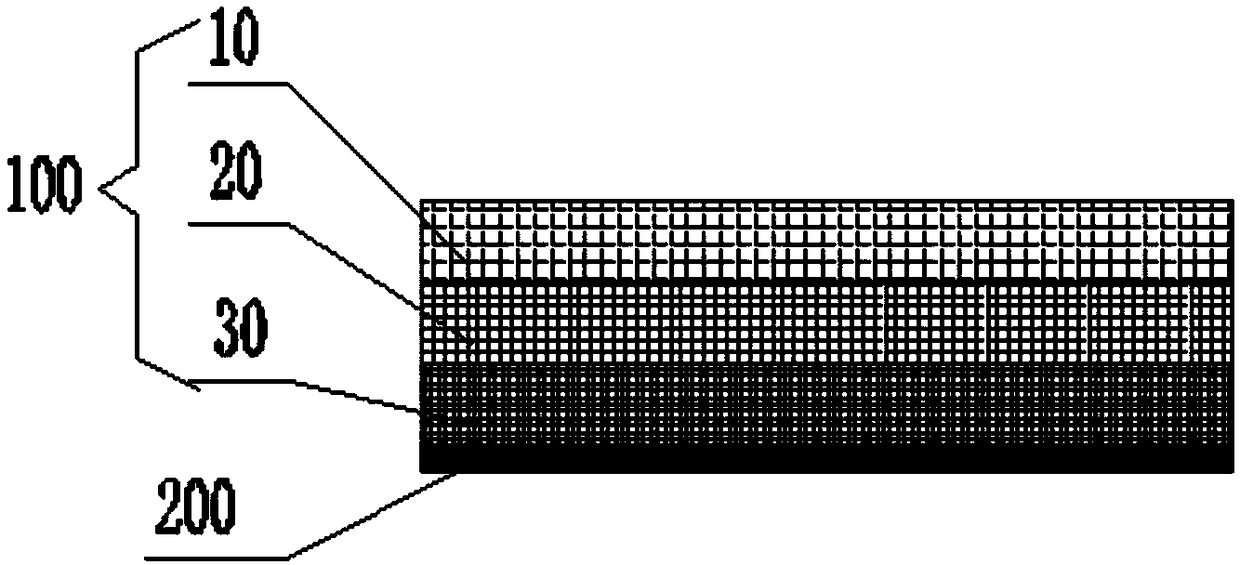

[0029] like image 3 As shown, the sound-insulating cotton in this embodiment includes a sound-absorbing material layer 100 and a sound-insulating material layer 200 . The sound-insulating material is a layer of rubber PVC; the sound-absorbing material 100 is composed of three layers, namely the sound-absorbing material 10 with a relatively small volume density (the first layer), and the sound-absorbing material 20 with a relatively medium volume density (the first layer). The second layer) and the sound-absorbing material 30 (the third layer) with a larger volume density, the three-layer sound-absorbing material is stacked up and down, and the edge and one or two places in the middle are sewn with sutures 40, such as Figure 4 As shown; the third layer 30 of the entire sound-absorbing material layer 100 ...

Embodiment 2

[0035] This embodiment relates to a compressor, and the outside of the compressor is covered with sound-insulating cotton laminated with various sound-absorbing materials.

[0036] like image 3 As shown, the sound-insulating cotton in this embodiment is the same as the sound-insulating cotton in Example 1, and the performance change rule of the sound-absorbing material is only different from that in the embodiment. In this embodiment, each layer of sound-absorbing material is 15mm thick, and 1mm behind the acoustic material.

Embodiment 3

[0038] This embodiment relates to a compressor, and the outside of the compressor is covered with sound-insulating cotton laminated with various sound-absorbing materials.

[0039] like image 3 As shown, the sound-insulating cotton in this embodiment is the same as the sound-insulating cotton in Example 1, and the performance change rule of the sound-absorbing material is only different from that in the embodiment. In this embodiment, each layer of sound-absorbing material is 4mm thick, and 3mm behind the acoustic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com