Method for preparing steaming pressure aeroconcrete by skarn type mine tailings

A technology of autoclaved gas filling and skarn, which is applied in applications, household utensils, ceramic products, etc., can solve the problems of insufficient heat insulation, high energy consumption, and insufficient durability, so as to broaden the range of raw materials, save lime, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

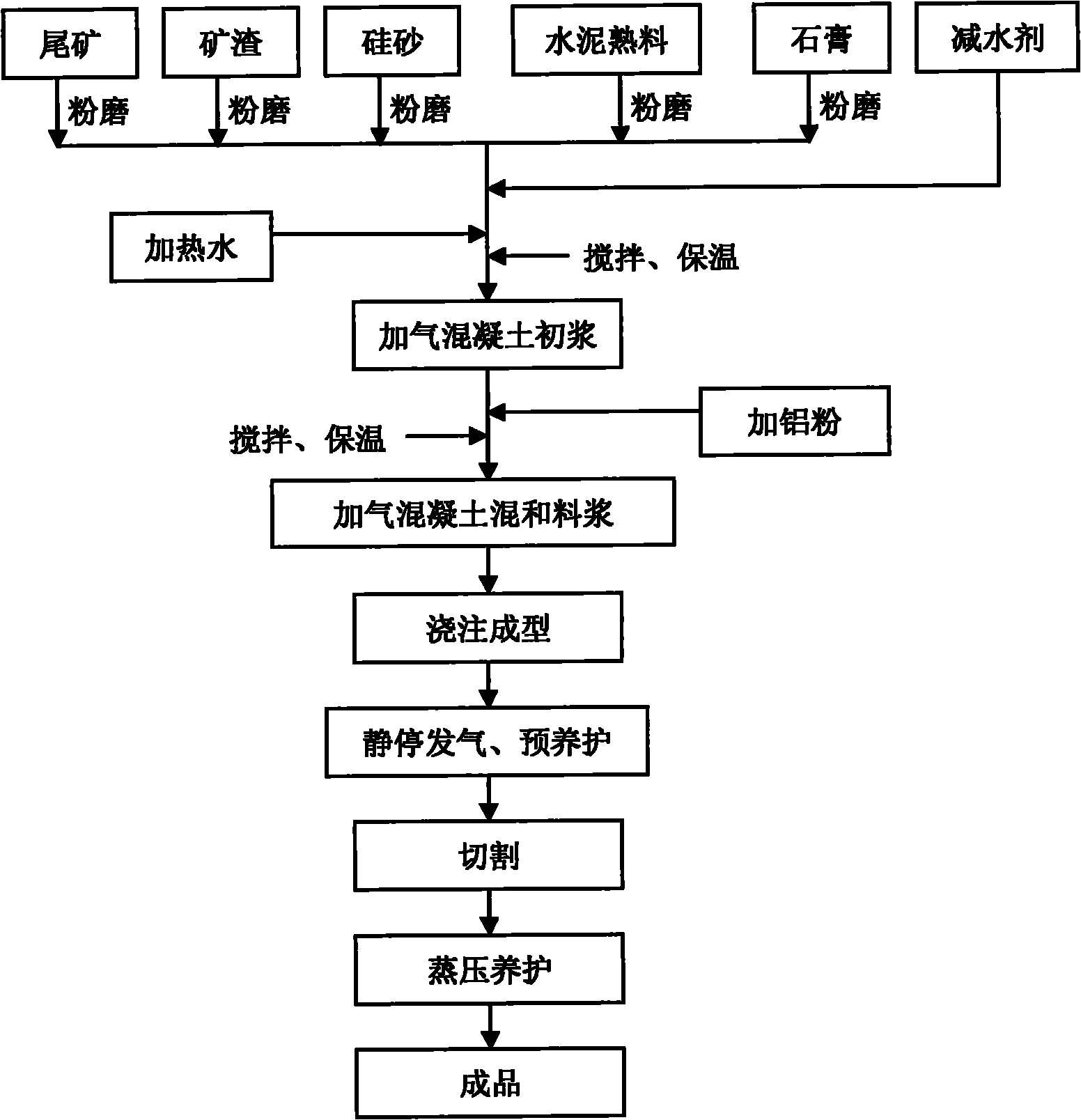

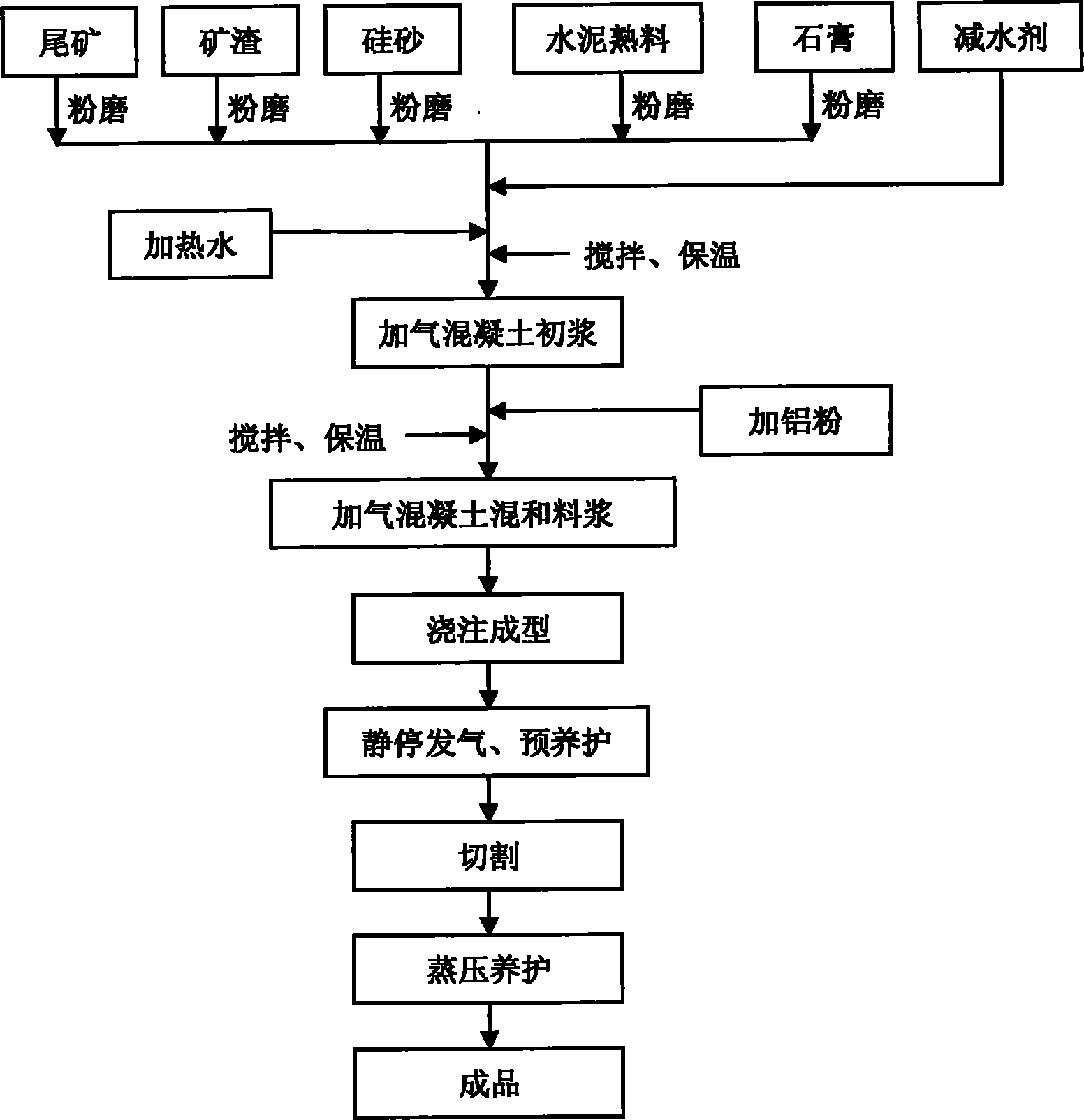

Method used

Image

Examples

Embodiment 1

[0015] (1) Grind the raw materials after drying, and grind the skarn-type tailings to a specific surface area of 681.7kg / m 2 ; Water-quenched blast furnace slag is ground to a specific surface area of 562.2kg / m 2 ; Silica sand is ground to a specific surface area of 999.7kg / m 2 ;Natural gypsum is finely ground to a specific surface area of 400kg / m 2 ; The cement clinker is ground to a specific surface area of 380kg / m 2 .

[0016] (2) The raw materials prepared in step (1) are prepared according to 30% of skarn tailings, 35% of water-quenched blast furnace slag, 20% of silica sand, 10% of cement clinker, and 5% of natural gypsum by weight percentage on a dry basis. Water reducing agent accounting for 0.75% of the total mass of the above dry mixed material and warm water at 48°C accounting for 40% of the total mass of the mixed dry material, stirred for 120 seconds, then added 0.07% aluminum powder and stirred for 40 seconds to obtain an air-entrained concrete mixtu...

Embodiment 2

[0022] (1) Grind the raw materials after drying, and grind the skarn-type tailings to a specific surface area of 561.6kg / m 2 ; Water-quenched blast furnace slag is ground to a specific surface area of 562.2kg / m 2 ; Silica sand is ground to a specific surface area of 999.7kg / m 2 ;Natural gypsum is finely ground to a specific surface area of 400kg / m 2 ; The cement clinker is ground to a specific surface area of 300kg / m 2 .

[0023] (2) The raw materials prepared in step (1) are prepared according to 30% of skarn tailings, 30% of water-quenched blast furnace slag, 25% of silica sand, 10% of cement clinker, and 5% of natural gypsum by weight percentage on a dry basis. Water reducing agent accounting for 0.6% of the total mass of the above mixed dry material and 53°C warm water accounting for 41.5% of the total mass of the mixed dry material, stirred for 120 seconds, then added 0.12% aluminum powder and stirred for 40 seconds to obtain an air-entrained concrete mixture...

Embodiment 3

[0029] (1) Grind each raw material after drying, and grind the skarn-type tailings to a specific surface area of 653.4kg / m 2 ; Water-quenched blast furnace slag is ground to a specific surface area of 542.7kg / m 2 ;Silica sand is finely ground to a specific surface area of 887.4kg / m 2 ;Natural gypsum is finely ground to a specific surface area of 400kg / m 2 ; The cement clinker is ground to a specific surface area of 380kg / m 2 .

[0030] (2) The raw materials prepared in step (1) are prepared according to 30% of skarn tailings, 40% of water-quenched blast furnace slag, 19% of silica sand, 6% of cement clinker, and 5% of natural gypsum according to the proportioning of the raw materials prepared in step (1), plus Water reducing agent accounting for 0.85% of the total mass of the above mixed dry material and 50°C warm water accounting for 40% of the total mass of the mixed dry material, stirred for 120 seconds, then added 0.1% aluminum powder and stirred for 40 second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com