Carbon-fiber needled preformed body with gradiently-changed body density

A prefabricated body and carbon fiber technology, applied in the direction of layered products, can solve the problems of shortening the preparation cycle, reducing production costs, and easy sealing, and achieve the effects of shortening the production cycle, saving manpower, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

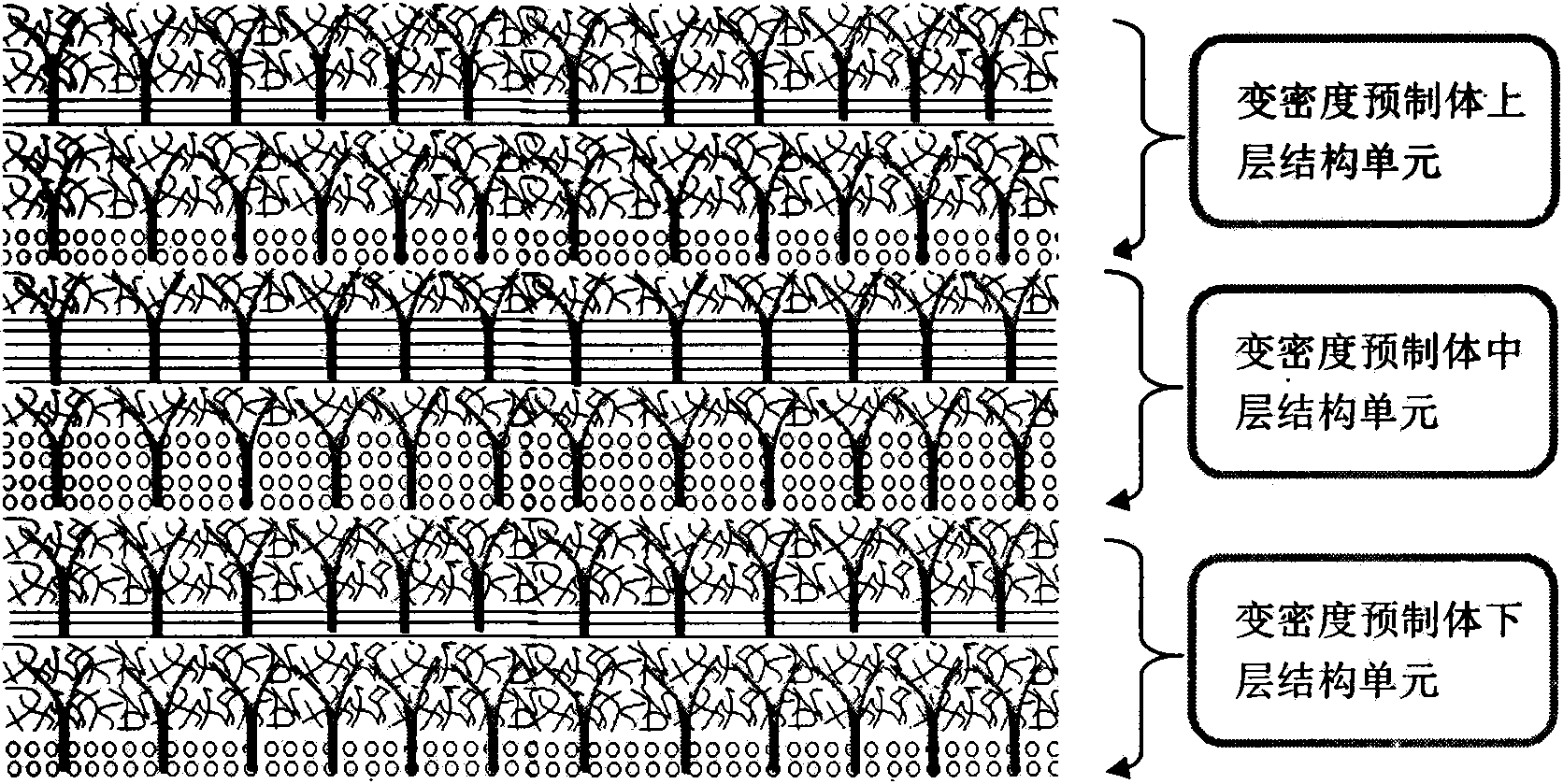

[0009] As shown in Figure 1, the carbon fiber needle-punched prefabricated body of the present invention is formed by three-layer carbon fiber needle-punched prefabricated body multi-angle layer-by-layer intersecting continuous acupuncture, wherein the density of the middle layer prefabricated body is higher than that of the upper and lower layers. The density is high, and each layer of prefabricated body is composed of a layer of 0° / 90° lay-up carbon cloth and a layer of net tire, which are continuously needled layer by layer. The single-layer thickness of the preform is 5-50mm, the interlayer density of the carbon fiber needle-punched preform is 16±1 layer / cm, the volume density of the upper and lower carbon fiber needle-punched preforms is 0.25-0.5, and the volume of the middle carbon fiber needle-punched preform is The density is 0.5-0.75.

[0010] The preparation method of the composite needle-punched preform mainly includes the following steps:

[0011] 1) Cut the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com