Light steel ladle permanent layer castable

A permanent layer, castable technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of rapid temperature drop of molten steel and rapid heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A castable for a light-weight ladle permanent layer, wherein the weight percentages of each component are: 1-25mm corundum 5%, 1-15mm bauxite 50%, 0.001-0.074mm corundum 15%, 0.001-0.074mm bauxite 13%, 0.01-0.5mm plastic foam particles 2%, pure calcium aluminate cement 5%, organic additive 5%, water reducer 5%.

[0012] In this embodiment, the corundum is fused white corundum with an aluminum content ≥ 98.5%; the aluminum content of the alumina is ≥ 70%. The organic additive is polyethylene fiber.

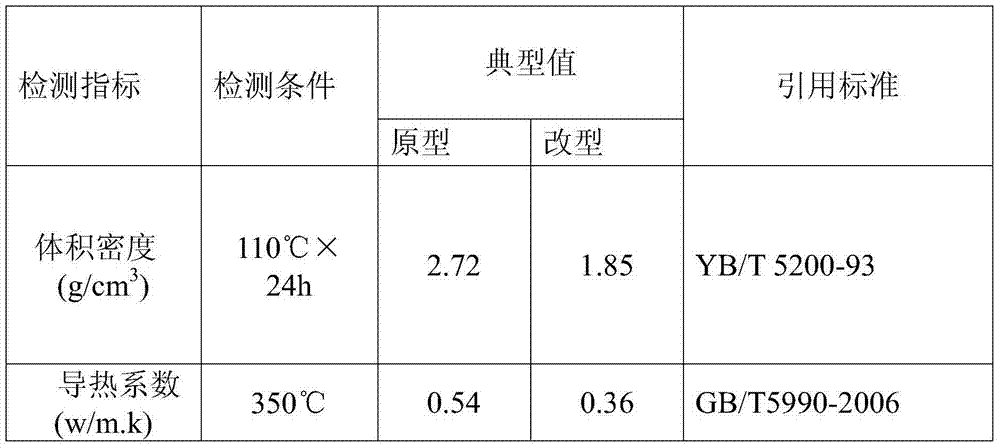

[0013] Since the plastic foam particles are added to the castable material of the permanent layer of the light ladle, after the plastic foam particles are heated and melted at a high temperature, uniformly distributed cavities below 0.5mm are formed in the castable material, which reduces the volume of the castable material of the permanent layer of the ladle. dense, so as to achieve the effect of heat preservation of molten steel, and at the same time, it does not change t...

Embodiment 2

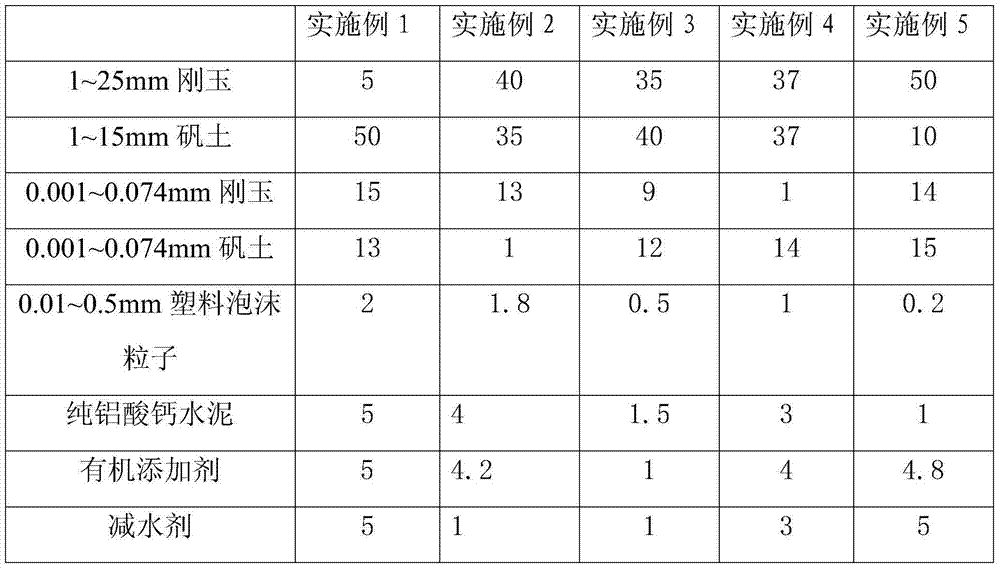

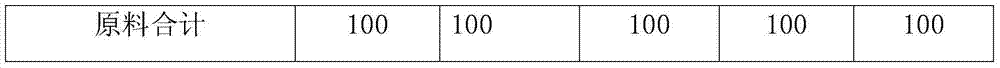

[0014] Example 2, Example 3, Example 4 and Example 5 refer to Table 1, and are similar to the previous examples, except that the organic additive is changed to high molecular polymer powder or polypropylene fiber, and will not be described in detail here. Table 1

[0015]

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com