A high-strength heat-insulating and wear-resistant castable for a catalytic cracking unit

A catalytic cracking device and castable technology, which is applied in the field of high-strength heat-insulating and wear-resistant castables, can solve the problems of easy separation and peeling of the wear-resistant layer and the heat-insulating layer, and achieve excellent thermal shock resistance, reduced dosage, and wear-resistant good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

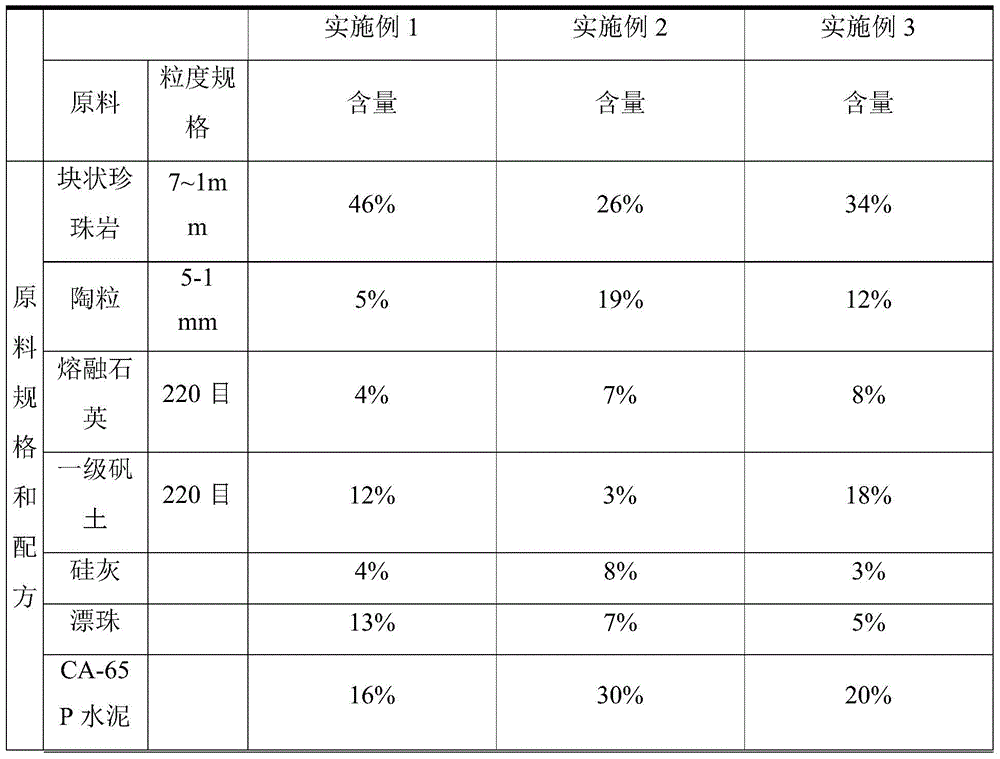

[0023] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

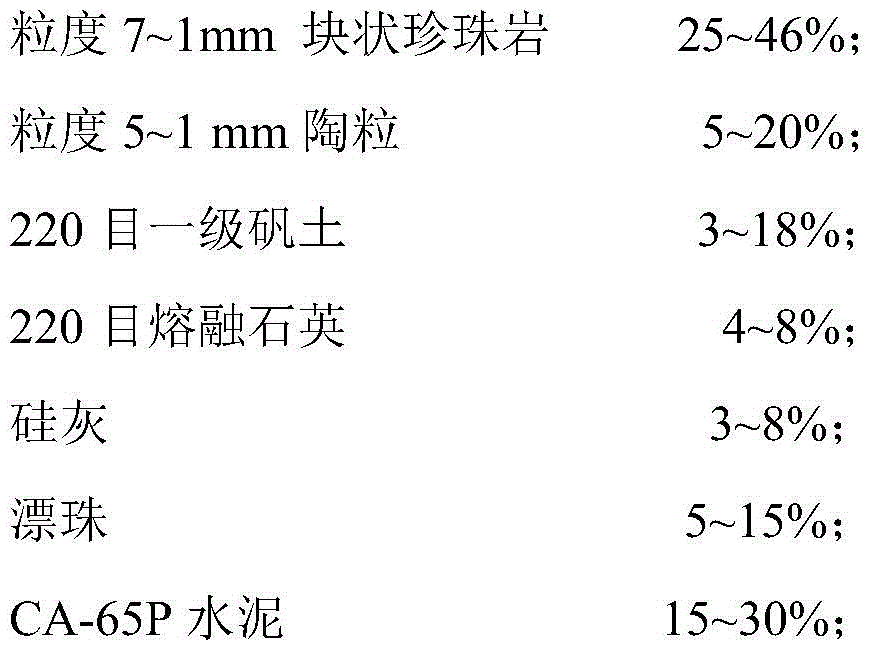

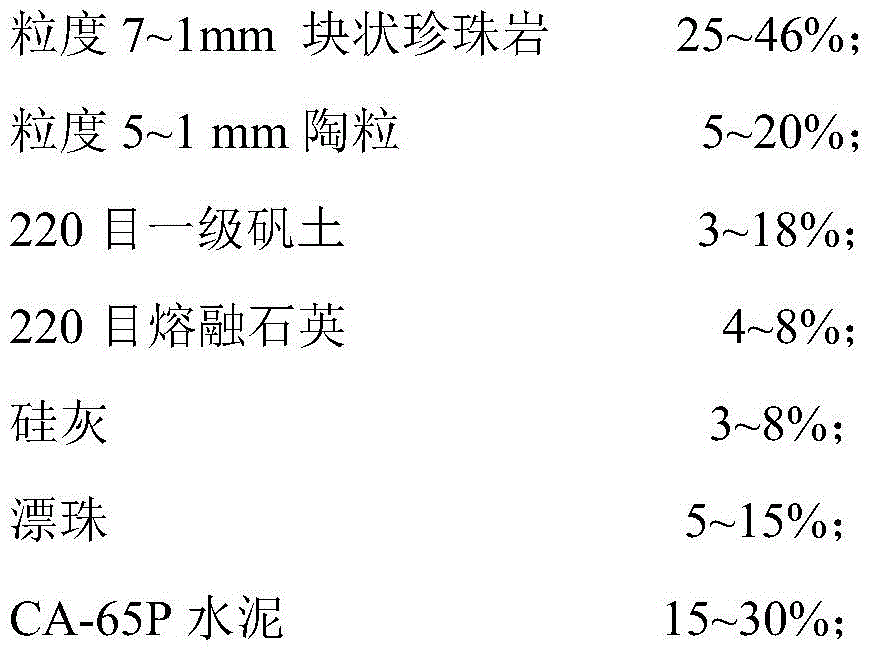

[0024] A high-strength heat-insulating and wear-resistant castable for a catalytic cracking unit, which includes the following components by weight percentage:

[0025]

[0026] The sum of the weight percentages of the above components is 100%;

[0027] Based on the sum of the weights of the above components, plus:

[0028] Polycarboxylic acid 0.1~0.15%;

[0029] Water 10-15%.

[0030] The method for preparing the above-mentioned high-strength heat-insulating and wear-resistant castable for the catalytic cracking unit is to prepare the formula amount of massive perlite with a particle size of 7-1 mm, ceramsite with a particle size of 5-1 mm, 220 mesh first-grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com