Mixing method of sliding bricks in steelmaking slide gate system

A sliding nozzle and sliding brick technology, which is applied in the field of refractory material production, can solve problems such as brick spallation, poor board surface, and irregular particle shape, and achieve the effects of improving deformation resistance, mud performance, and reducing harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

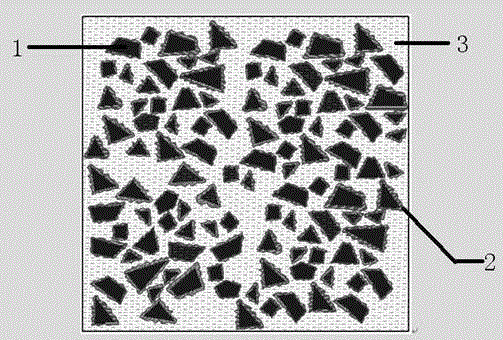

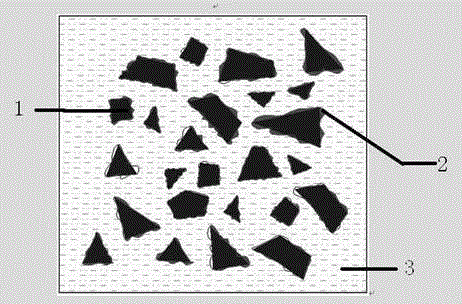

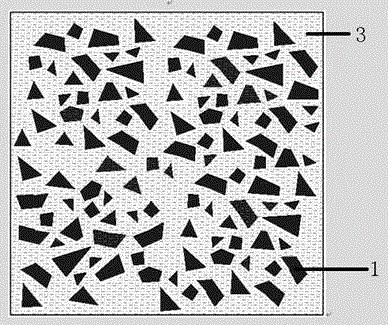

Image

Examples

Embodiment 1

[0043] A method for mixing sliding bricks in a sliding nozzle system for steelmaking, comprising the following steps: firstly adding granules and all powder materials into a mixing equipment at the same time, then stirring in the mixing equipment for 3 to 5 minutes; finally adding the combined The agent is stirred for 15 to 30 minutes and then discharged; among them, polyhydroxyacrylic acid is added to the powder.

[0044] The added amount of the binder is 3%-5% of the total weight of the granule and powder.

[0045] The binder is liquid phenolic resin, thermoplastic phenolic resin or thermosetting phenolic resin.

[0046] The added amount of the polyhydroxyacrylic acid is 0.5-3% of the total weight of the particles and the powder.

Embodiment 2

[0048] A method for kneading sliding bricks in a sliding nozzle system for steelmaking, comprising the following steps: firstly, adding granules and all powder materials to a kneading equipment successively, and then stirring in the kneading equipment for 3 to 5 minutes;

[0049] Finally, add the binder and stir for 15 to 30 minutes before discharging; wherein polyhydroxyacrylic acid is added to the powder.

[0050] The added amount of the binder is 3%-5% of the total weight of the granule and powder.

[0051] The binder is liquid phenolic resin, thermoplastic phenolic resin or thermosetting phenolic resin.

[0052] The added amount of the polyhydroxyacrylic acid is 0.5-3% of the total weight of the particles and the powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com