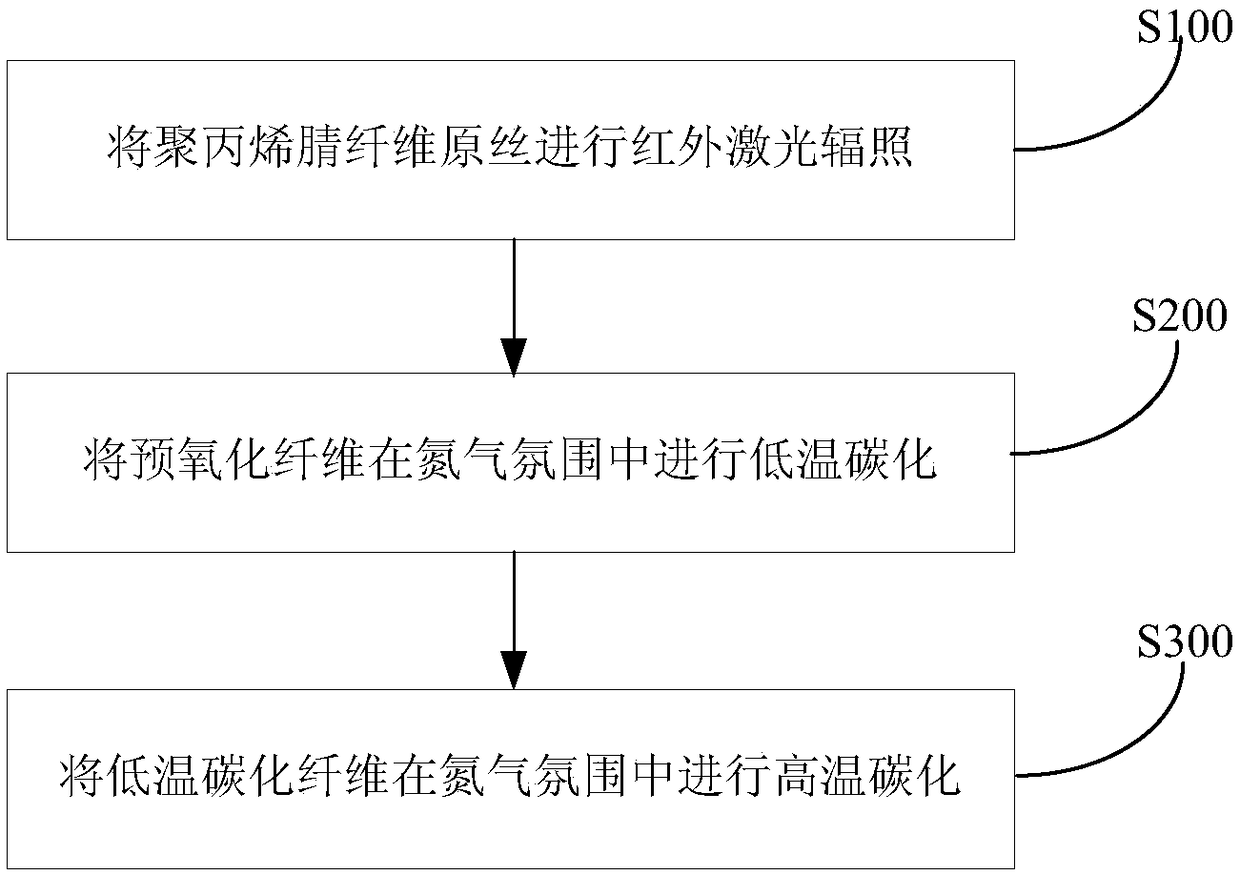

Method for preparing polyacrylonitrile carbon fibers

A polyacrylonitrile carbon fiber and fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of large space for energy saving and consumption reduction, and achieve the effects of improving production efficiency, reducing production costs, high strength and orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

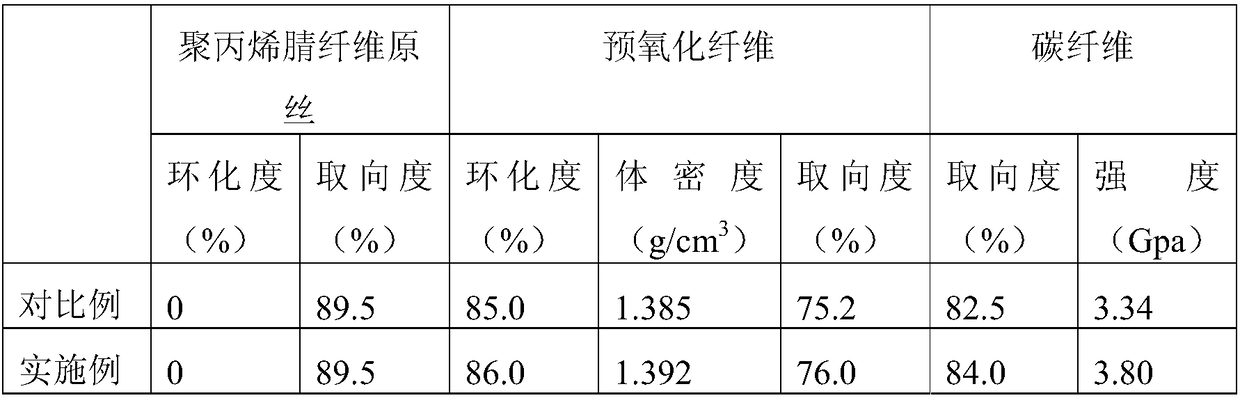

[0035] Select 1K (i.e. 1000 filaments / bundle) polyacrylonitrile precursor containing acrylamide copolymer (the content of acrylonitrile is not less than 92wt%) (denoted as: precursor A), first carry out 5 in the air atmosphere Segment infrared laser irradiation, the irradiation power density is 4.0kW / cm 2 、4.3kW / cm 2 、4.6kW / cm 2 、4.9kW / cm 2 、5.2kW / cm 2 , each section of residence time is 5min, a total of 25min, while controlling the tension as follows: the first and second section tension control is 30Mpa, the third section tension control is 24Mpa, the fourth and fifth section tension control is 30Mpa, to obtain polyacrylonitrile preoxidized fiber , and then the polyacrylonitrile pre-oxidized fiber is subjected to low-temperature carbonization at 400°C, 450°C, 600°C and 850°C under the protection of nitrogen, the residence time is 15min, and the tension is controlled at 12Mpa; finally, it enters the high-temperature carbonization furnace at 1300°C, The residence time is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com