Explosion cladding process of steel bond hard alloy and carbon steel

A technology of steel-bonded cemented carbide and composite technology, applied in metal material coating technology, coating and other directions, can solve the problems of difficult composite of small workpieces, complicated process, high brittleness of tool steel, etc. Grinding, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

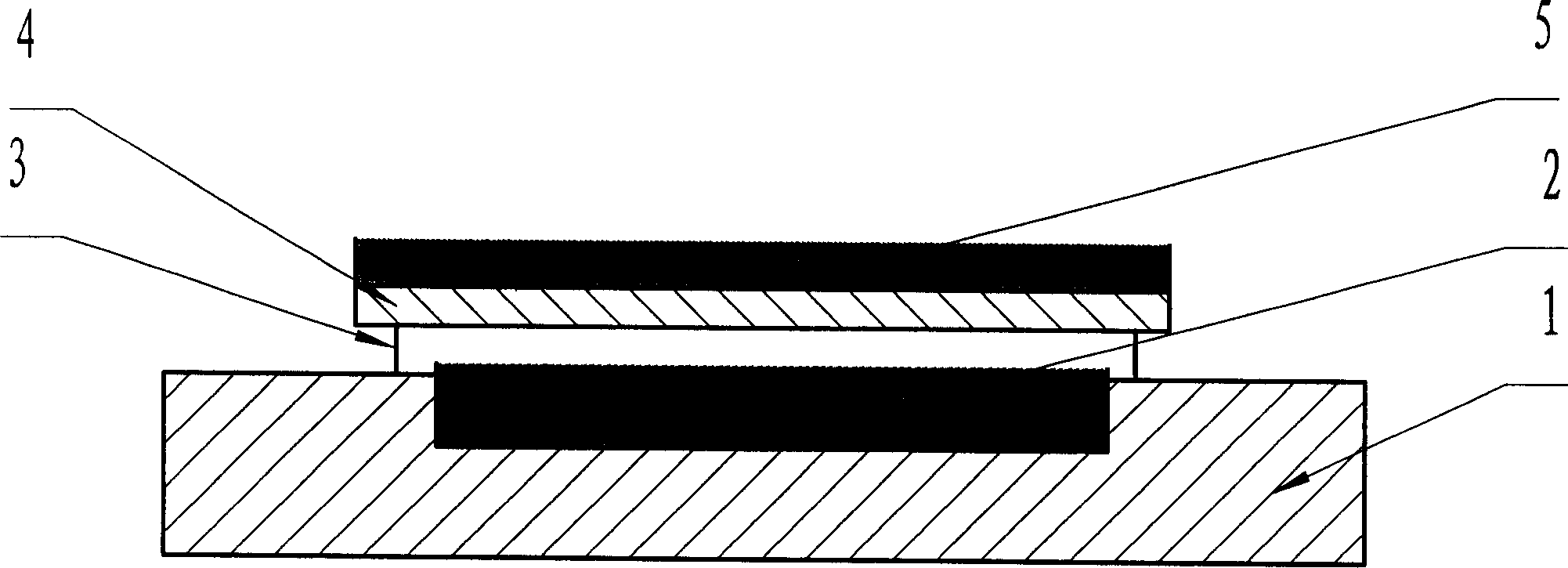

[0014] Take the production of refractory brick molds as an example. Mill a groove of about 280×160×5mm on the surface of a piece of 45 steel; put the prepared cemented carbide powder (Wc: 50%, C: 1.0%, Mo: 1.5%, Cr: 3.0%, and the balance is iron ) Add 1.0% of the weight of the alloy powder into the cemented carbide binder ball mill and stir evenly, and fill it into the carbon steel milled groove for compaction. After the binder is dry, place it on the flat land or sand as a whole On the ground, a carbon steel plate with a thickness of 3mm and an area slightly larger than the groove is supported on the carbon steel substrate by four thin metal sheets as a doubler plate, which is 8cm away from the base plate. Explosives are placed on the doubler plate and detonated by an 8# detonator; Carbon steel plate on the surface, liquid phase sintering process (temperature 600°C, heat preservation for 2 hours, heat preservation at 1250°C for 2 hours and cooling with the furnace), heat trea...

Embodiment 2

[0016] Take the production of refractory brick molds as an example. Mill a groove of about 280×180×6mm on the surface of a piece of 45 steel; put the prepared cemented carbide powder (Wc: 30%, C: 0.3%, Mo: 0.5%, Cr: 0.5%, and the balance is iron ) Add 1.5% of the alloy powder’s weight of paraffin as a binder, ball mill and mix evenly, and fill it into the carbon steel milled groove for compaction. After the binder is dry, place it flat on the flat land or sand as a whole A carbon steel plate with a thickness of 4mm and an area slightly larger than the groove is supported by four thin metal sheets on the carbon steel substrate as a doubler plate, 12cm away from the base plate, explosives are placed on the doubler plate and detonated by an 8# detonator; the surface is milled off Carbon steel plate, liquid phase sintering process (temperature 600°C, heat preservation for 2 hours, heat preservation at 1300°C for 2 hours and cooling with the furnace), heat treatment at 820°C for 3 ...

Embodiment 3

[0018] Take the production of refractory brick molds as an example. Mill a groove of about 280×210×8mm on the surface of a piece of 45 steel; put the prepared cemented carbide powder (Wc: 40%, C: 0.6%, Mo: 0.6%, Cr: 0.6%, and the balance is iron ) Add 2.0% resin of the weight of the alloy powder as a binder, ball mill and mix evenly, and fill it into the carbon steel milled groove for compaction. After the binder is dry, place it flat on the flat land or sand as a whole A carbon steel plate with a thickness of 4mm and an area slightly larger than the groove is supported by four thin metal sheets on the carbon steel substrate as a doubler plate, 16cm away from the base plate, explosives are placed on the doubler plate and detonated by a detonator; the steel plate on the surface is milled off , liquid phase sintering process (temperature 500 ° C for 2 hours, 1400 ° C for 1 hour with furnace cooling), heat treatment at 840 ° C for 3 hours and air cooling to obtain a highly wear-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com