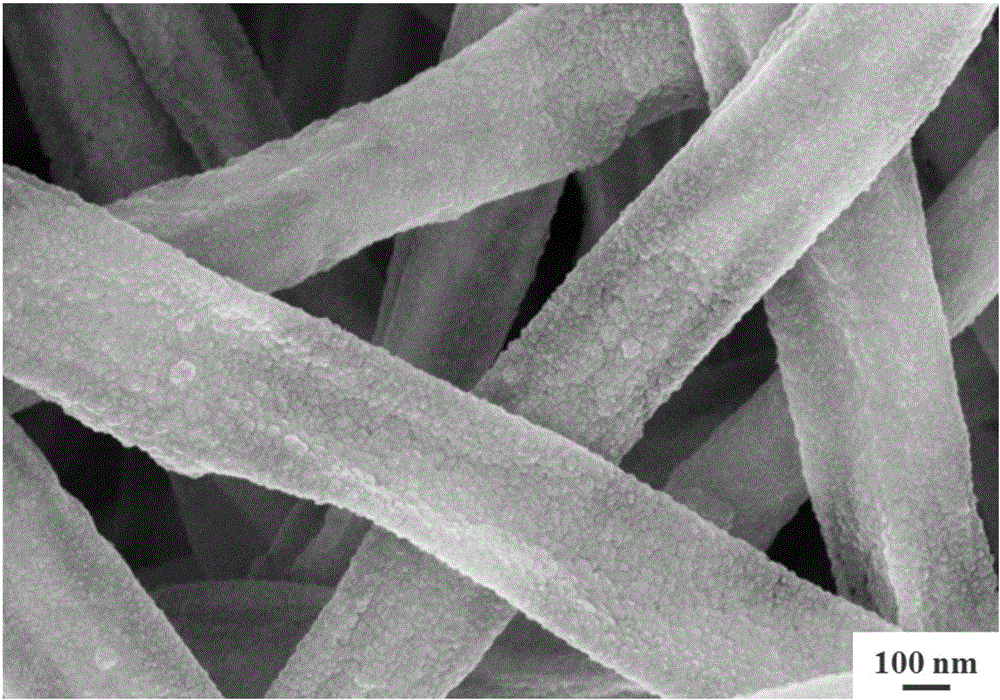

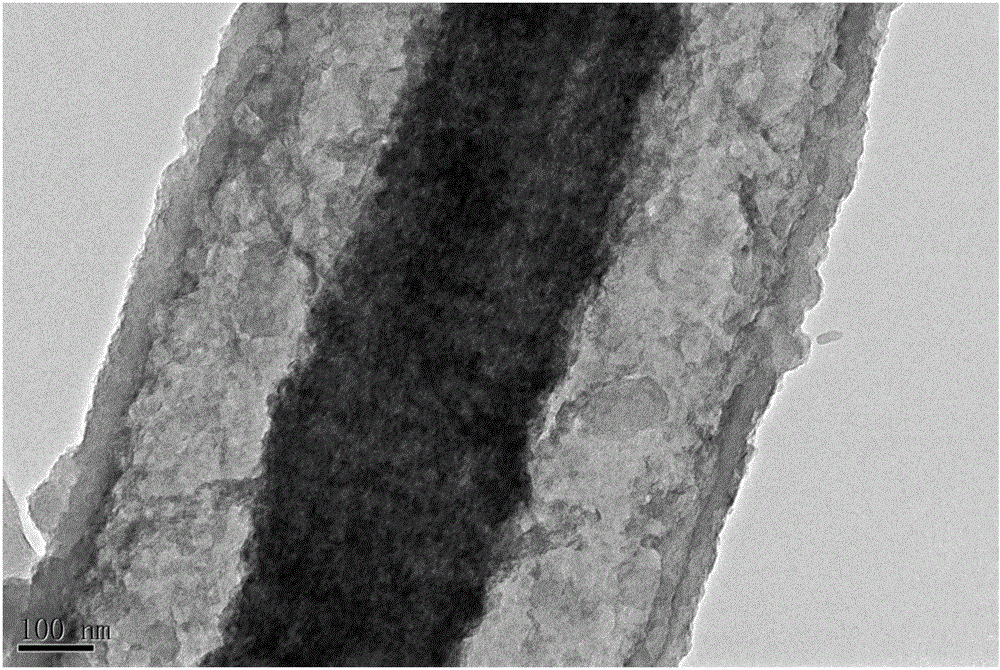

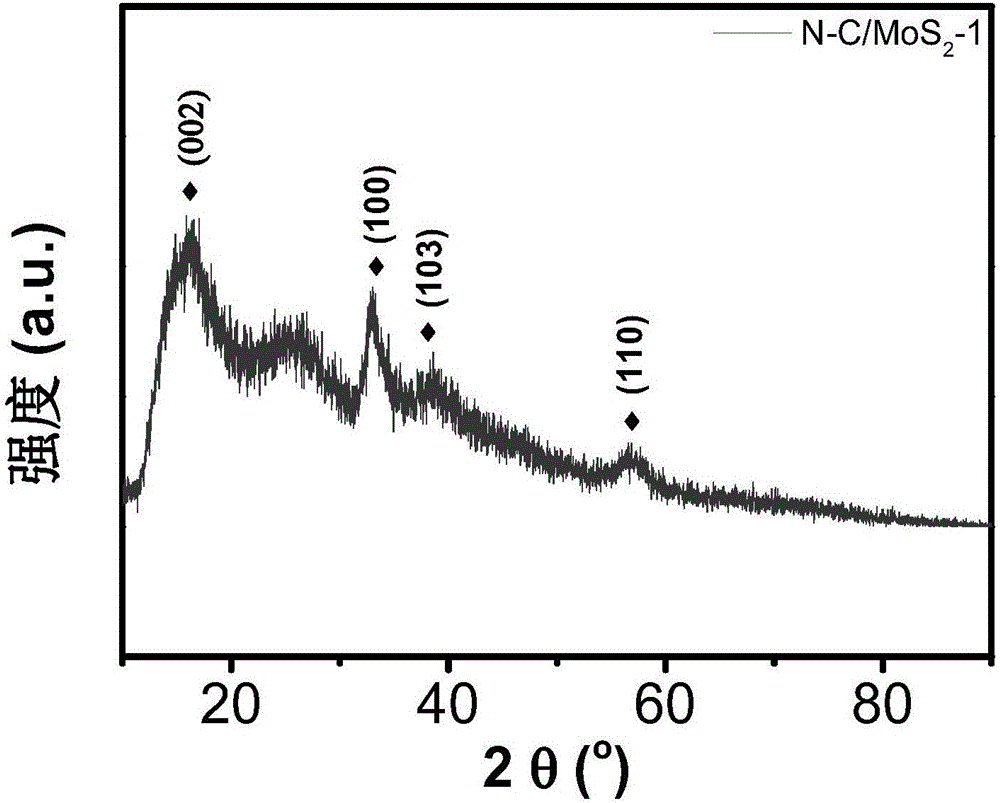

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

A nanofiber, molybdenum disulfide technology, applied in the field of energy storage materials, can solve problems such as hindering the effective transmission of electrolyte, decrease in cycle stability, and attenuation of specific capacity, and achieve the advantages of intercalation and desorption reactions, high specific capacity, increased specific capacity, etc. The effect of the flow of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 0.6g of polymethyl methacrylate and 0.3g of ammonium thiomolybdate into 10mL of N,N-dimethylformamide and stir for 120min. After uniformity, the spinning stock solution is obtained and set aside;

[0035] (2) Add the spinning stock solution in (1) to the syringe and carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, and a bolus injection speed of 0.1mm / min to obtain polymethyl methacrylate / sulfur Ammonium molybdate nanofibers;

[0036] (3) drying the obtained fibers in an oven at 60°C, and then treating them with a plasma surface cleaner for 10 minutes to obtain fibers with better hydrophilicity;

[0037] (4) preparation concentration is the hydrochloric acid aqueous solution of 1M, with this solution preparation 0.03M ferric chloride hydrochloric acid solution and 0.03M pyrrole hydrochloric acid solution each 500mL, 0.25g fiber film is put into pyrrole / hydrochloric acid solution and soaks 60min;

[0038](5) Add t...

Embodiment 2

[0044] (1) Add 0.6g of polymethyl methacrylate and 0.6g of ammonium thiomolybdate into 10mL of N,N-dimethylformamide and stir for 120min. After uniformity, the spinning stock solution is obtained and set aside;

[0045] (2) Add the spinning stock solution in (1) to the syringe and carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, and a bolus injection speed of 0.1mm / min to obtain polymethyl methacrylate / sulfur Ammonium molybdate nanofibers;

[0046] (3) drying the obtained fibers in an oven at 60°C, and then treating them with a plasma surface cleaner for 10 minutes to obtain fibers with better hydrophilicity;

[0047] (4) preparation concentration is the hydrochloric acid aqueous solution of 1M, with this solution preparation 0.03M ferric chloride hydrochloric acid solution and 0.03M pyrrole hydrochloric acid solution each 500mL, 0.25g fiber film is put into pyrrole / hydrochloric acid solution and soaks 60min;

[0048] (5) Add ...

Embodiment 3

[0052] (1) Add 0.6g of polymethyl methacrylate and 0.3g of ammonium thiomolybdate into 10mL of N,N-dimethylformamide and stir for 120min. After uniformity, the spinning stock solution is obtained and set aside;

[0053] (2) Add the spinning stock solution in (1) to the syringe and carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, and a bolus injection speed of 0.1mm / min to obtain polymethyl methacrylate / sulfur Ammonium molybdate nanofibers;

[0054] (3) drying the obtained fibers in an oven at 60°C, and then treating them with a plasma surface cleaner for 10 minutes to obtain fibers with better hydrophilicity;

[0055] (4) preparation concentration is the hydrochloric acid aqueous solution of 1M, with this solution preparation 0.05M ferric chloride hydrochloric acid solution and 0.05M pyrrole hydrochloric acid solution each 500mL, 0.25g fiber film is put into pyrrole / hydrochloric acid solution and soaks 60min;

[0056] (5) Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com