Glass fireproof liquid and application thereof

A technology of fireproof liquid and glass, which is applied in the direction of glass/slag layered products, layered products, synthetic resin layered products, etc. It can solve the problems of low adhesion of fireproof liquid, poor anti-aging performance, and affecting fireproof performance. Achieve the effects of improving compatibility, increasing particle size, and increasing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

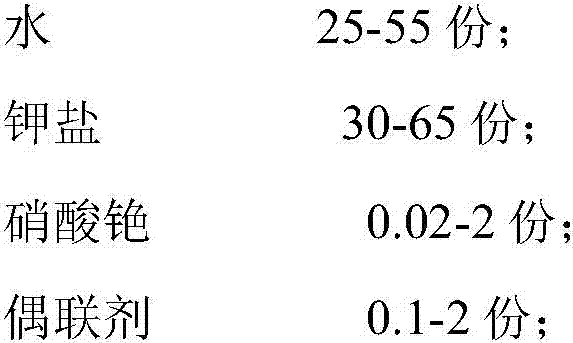

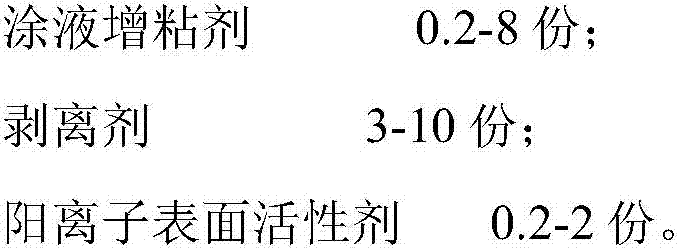

[0049] Preparation of fireproofing liquid: Take 15g of potassium phosphate, 5g of potassium fluoride, 10g of potassium nitrate, 5g of potassium stannate, 0.02g of cesium nitrate, 5g of gelatin, 1g of formic acid, and 40g of water, stir well, and then add vinyl three as a coupling agent. Ethoxysilane 1g is made into fireproof liquid.

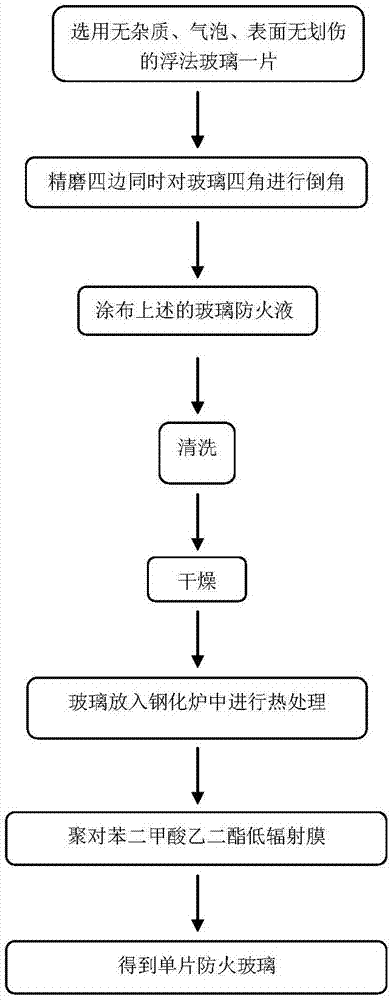

[0050] Application of fire protection fluid:

[0051] (1) Choose a piece of float glass with a thickness of 6mm without impurities, bubbles, and no scratches on the surface, and chamfer the four corners of the glass at the same time, so that the inclination angle of the finely ground edge is 154°, and the chamfer is the radius A safety angle of 3mm;

[0052] (2) Evenly spray the fireproof liquid on the finely ground float glass, the spraying amount is 20g / m2, and let it stand for 0.5h after spraying, so that the fireproof liquid can be fully exchanged on the surface of the float glass;

[0053] (3) the glass obtained in step (2) is put into cle...

Embodiment 2

[0058] Preparation of fireproof liquid: Take 30g of potassium phosphate, 13g of potassium fluoride, 3g of potassium stannate, 2g of cesium nitrate, 0.2g of gelatin, 2g of formic acid, and 55g of water, stir well, then add vinyltriethoxysilane as a coupling agent 2g is made into fireproof liquid.

[0059] Application of fire protection fluid:

[0060] (1) Select a piece of float glass with a thickness of 8mm without impurities, bubbles, and scratches on the surface, and chamfer the four corners of the glass at the same time, so that the inclination angle of the finely ground edge is 170°, and the chamfer is the radius A safety angle of 5mm;

[0061] (2) Evenly spray the fireproof liquid on the finely ground float glass, the spraying amount is 30g / m2, and let it stand for 1 hour after spraying, so that the fireproof liquid can be fully exchanged on the surface of the float glass;

[0062] (3) the glass obtained in step (2) is put into clear water for cleaning, and the unabsorb...

Embodiment 3

[0067] Preparation of fireproof liquid: Take 20g of potassium phosphate, 20g of potassium fluoride, 25g of potassium nitrate, 10g of potassium stannate, 0.02g of cesium nitrate, 8g of gelatin, 0.2g of formic acid, and 25g of water, stir well, then add vinyl as coupling agent Triethoxysilane 0.1g is formulated as a fireproof liquid.

[0068] Application of fire protection fluid:

[0069] (1) Choose a piece of float glass with a thickness of 10mm without impurities, bubbles, and scratches on the surface, and chamfer the four corners of the glass at the same time, so that the inclination angle of the finely ground edge is 160°, and the chamfer is the radius A safety angle of 4mm;

[0070] (2) Evenly spray the fireproof liquid on the finely ground float glass, the spraying amount is 25g / m2, and let it stand for 0.8h after spraying, so that the fireproof liquid can be fully exchanged on the surface of the float glass;

[0071] (3) the glass obtained in step (2) is put into clear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com