Cellulose-based composite material with three-dimensional porous structure and preparation method of cellulose-based composite material

A cellulose-based, three-dimensional porous technology, applied in the field of chemical materials, can solve problems such as the controllability of structure and performance, the limitations of large-scale application of ultrasonic dispersion methods, harsh conditions, etc., and achieve high surface reactivity, structural performance, etc. Adjustable, widely used effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

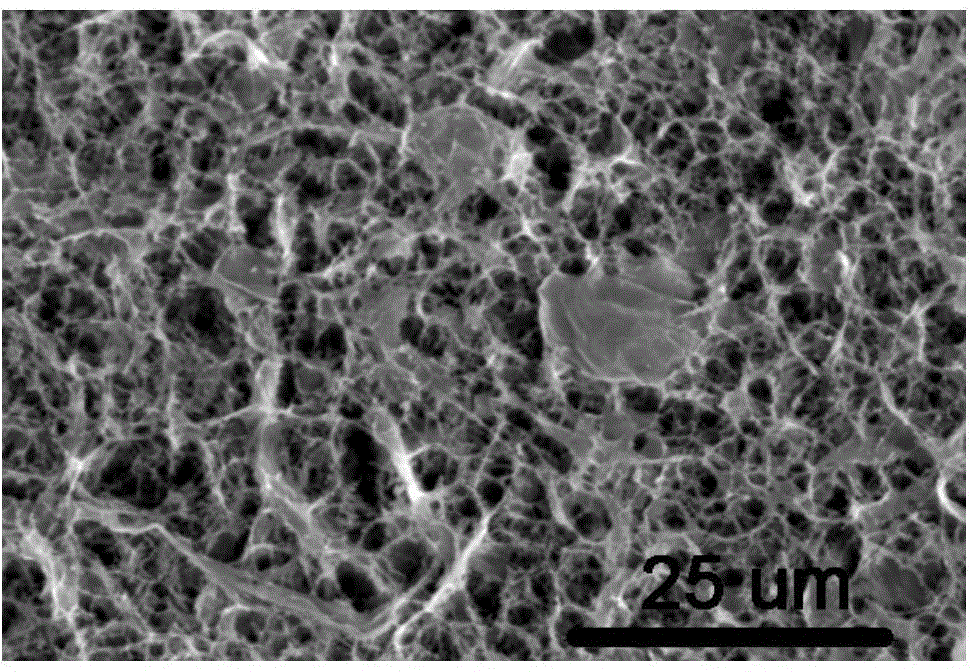

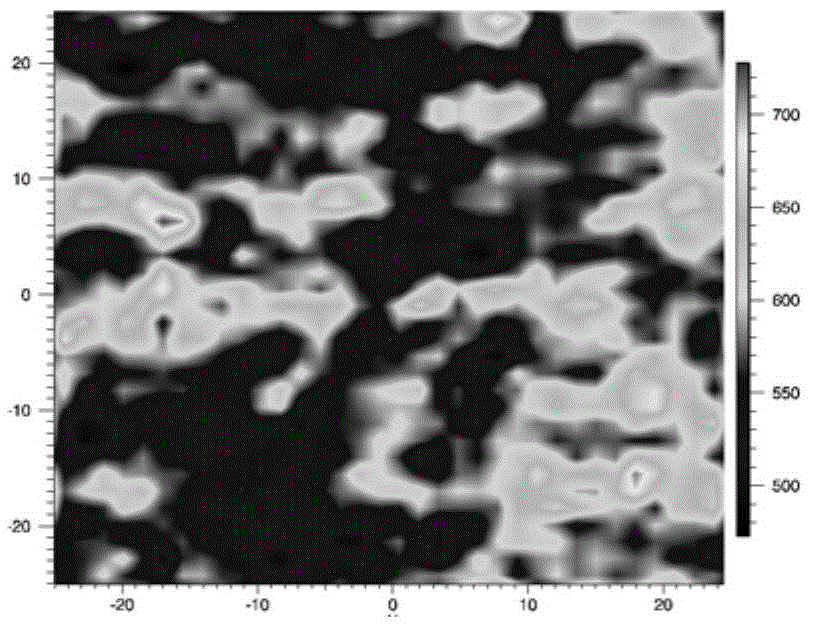

[0033] The present invention also provides a method for preparing the above-mentioned cellulose-based composite material with a three-dimensional porous structure, comprising the following steps:

[0034] (1) Mix the cellulose solution with a mass fraction of 2 to 10% and the graphene oxide concentrated dispersion liquid with a mass fraction of 0.5 to 10%, and carry out shear dispersion, and the time of the shear dispersion is 2 to 8h to obtain Composite system of graphene oxide and cellulose;

[0035] (2) adding a flocculant to the composite system of graphene oxide and cellulose to obtain flocs;

[0036] (3) the floc obtained in step (2) is soaked and washed with deionized water more than twice to obtain graphene oxide / cellulose hydrogel;

[0037] (4) Put the graphene oxide / cellulose hydrogel in liquid nitrogen to freeze for 0.5-6h, and then freeze-dry at -45~-55°C for 45-50h to obtain a cellulose-based composite material with a three-dimensional porous structure .

[003...

Embodiment 1

[0049] Step (1), after the natural graphite is oxidized by the Hummers method or the improved Hummers method, it is repeatedly washed with deionized water and centrifuged, and the concentrated dispersion of graphene oxide in the lower layer is taken, and its mass percentage concentration is calibrated to be 4.2wt%, and placed in a refrigerator Store in the refrigerator for later use.

[0050] Step (2), the cellulose solution preparation standard that is 4.0wt% by mass percent content, cellulose is added into cellulose alkali urine solvent (solvent component has sodium hydroxide, urea and deionized water, described sodium hydroxide, The mass ratio of urea and deionized water is 5.8:10:84.2) to swell and evenly disperse, and then put it in the refrigerator to freeze for 24 hours, then take it out to thaw and shake vigorously to room temperature to form a clear and transparent cellulose solution.

[0051] Step (3), add 13.125g (i.e. 525mg cellulose) of thawed cellulose solution w...

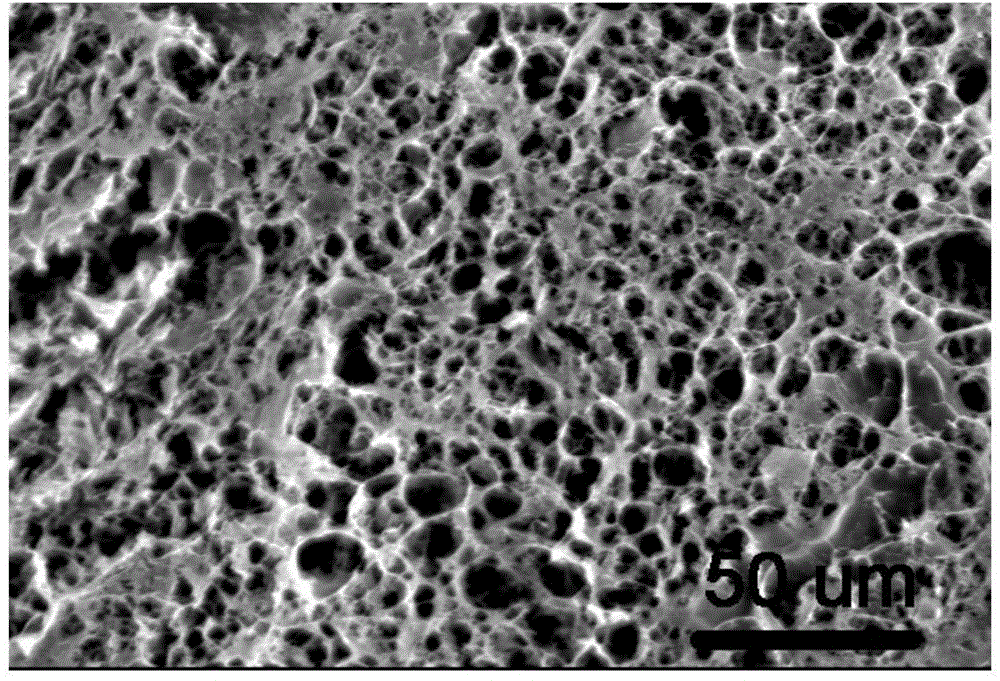

Embodiment 2

[0053] According to the preparation method of embodiment 1, the difference is that the amount of graphite oxide concentrated dispersion is 0.625g, and the ball milling time is all unified as 6h, adopts the plastic mold frame molding of 10mm * 30mm * 0.2mm, obtains containing 5% graphene oxide ( A cellulose-based three-dimensional porous sheet based on the mass percentage of graphene oxide and cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com