Injector structure capable of preventing body from being overheated

An injector and overheating technology, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as difficulty in meeting the extreme working environment of gas generators, uneven nozzle annular gaps, and unfavorable thermal protection of the body , to achieve the effects of good combustion stability, easy promotion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

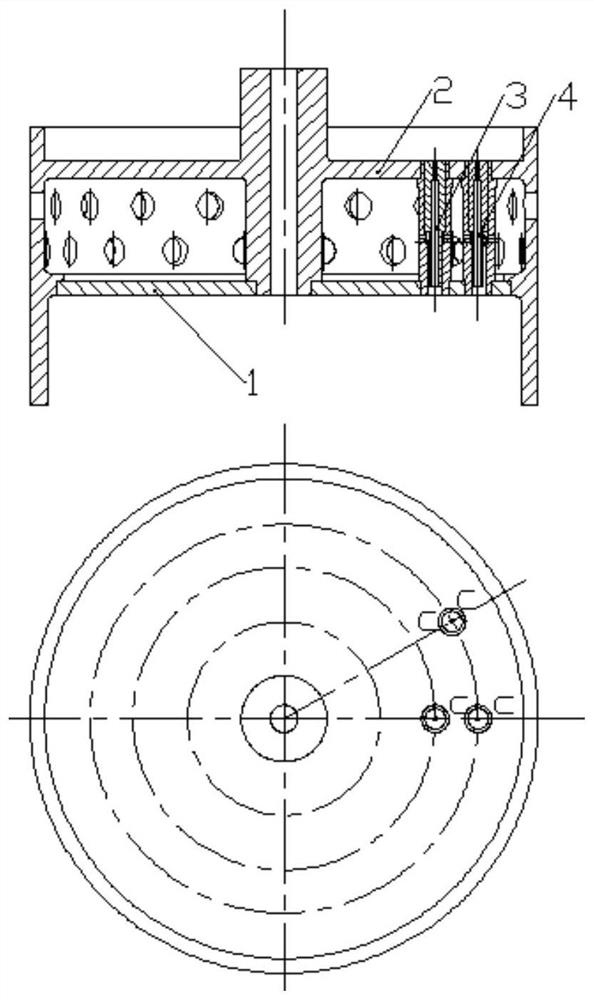

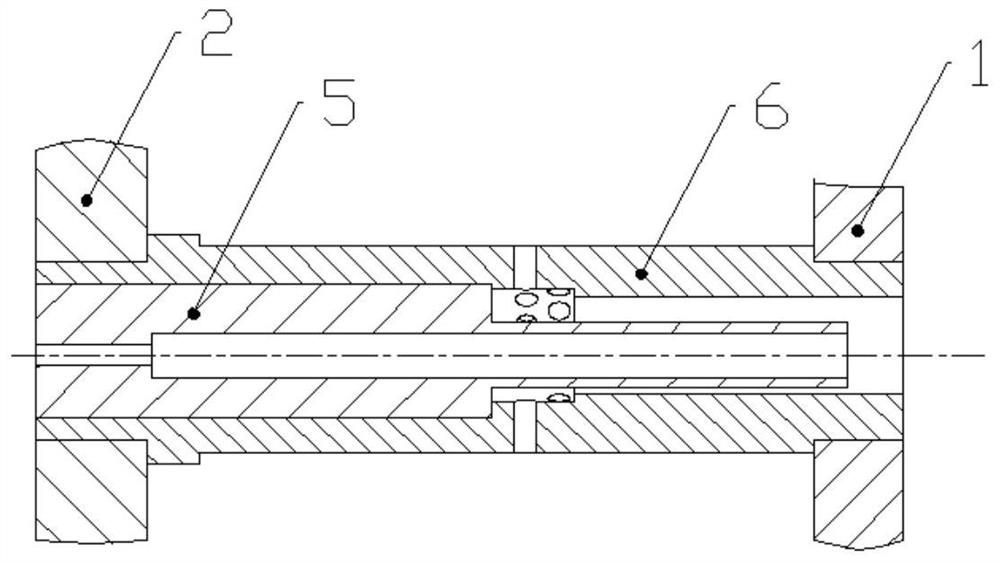

[0033] Such as figure 1 As shown, an injector structure for preventing overheating of the body includes a base 1, an injector base 2, a coaxial nozzle injection unit 3, and an eccentric nozzle injection unit 4. A bottom 1 and an injector base 2 form a fuel chamber, and the upper part of the injector base 2 is an oxidant chamber. The outermost ring nozzle of the injector adopts the eccentric nozzle injection unit 4, and the other ring nozzles adopt the coaxial nozzle injection unit 3.

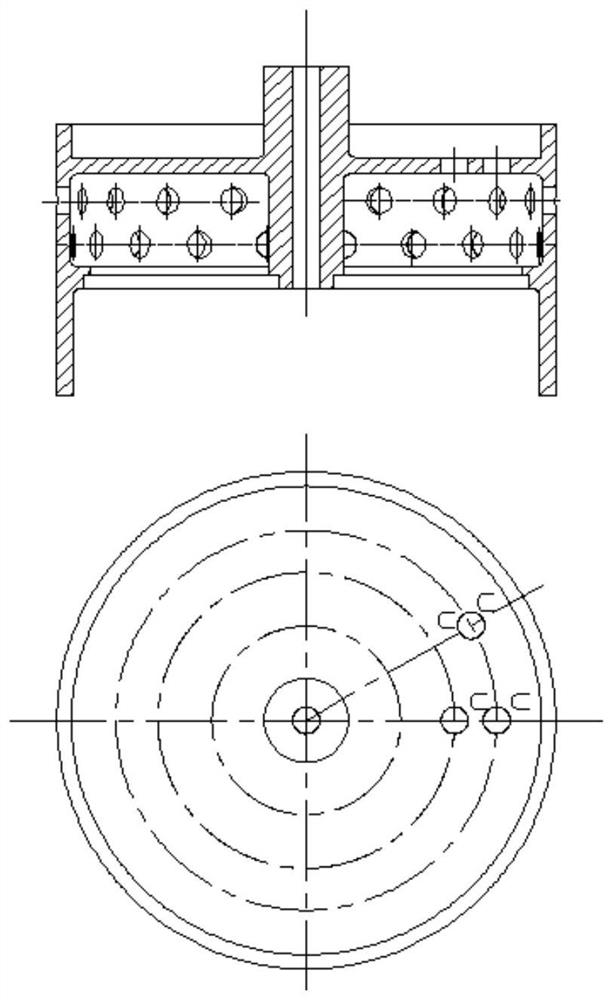

[0034] Such as figure 2 As shown, there are several rows of radial holes in the radial direction of the injector base 2 for more uniform fuel entering the fuel cavity; multiple circles of several holes are opened on the bottom plate of the injector ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com