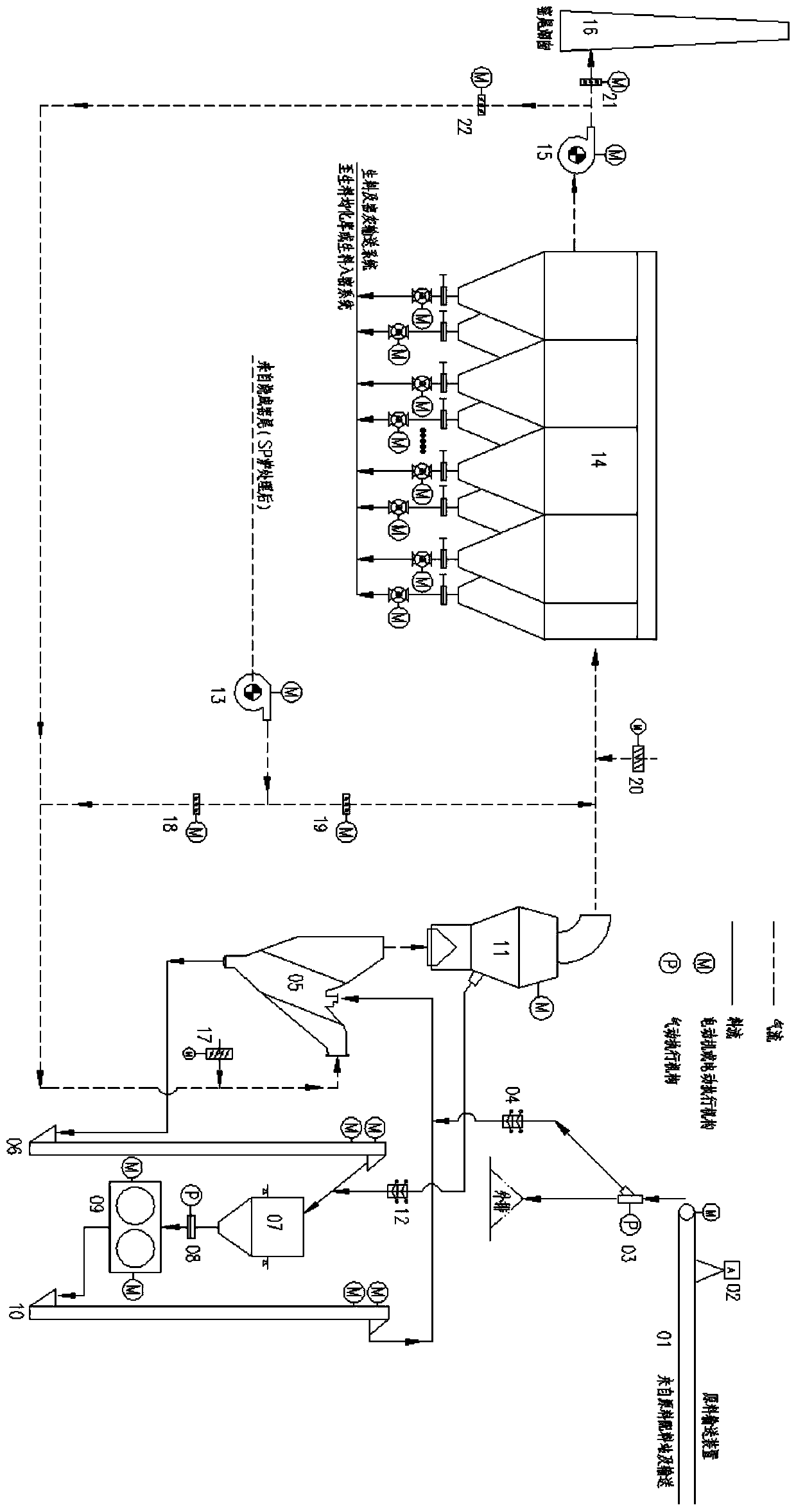

Final powder grinding double-fan system for raw material roller press and rolling method

A roller press and double blower technology, applied in the field of roller presses, can solve the problems of large floor area, many fault points, dusting of blades, etc., to reduce equipment maintenance workload, reduce equipment failure points, and reduce system resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] Concrete technical implementation condition of the present invention is:

[0021] 1. The final grinding system of the raw material roller press has the significant advantage of less resistance in the grinding system;

[0022] 2. At present, domestic cement clinker production lines are basically equipped with waste heat power generation systems. The temperature of the exhaust gas at the outlet of the high-temperature fan at the kiln tail is low. The temperature of the exhaust gas can be adjusted according to the moisture content of the raw materials. All are sent to the raw material grinding system for raw material drying, minimizing the consumption of circulating air and fresh air;

[0023] 3. With the rapid development of centrifugal fan technology, the fan performance curve can be designed and manufactured according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com