Additive for firefighting water

A technology of fire-fighting water and additives, which is applied to fire-fighting equipment, etc., can solve the problems of high fire-extinguishing agent prices, achieve low surface tension, prevent fire re-ignition, and increase fire-extinguishing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

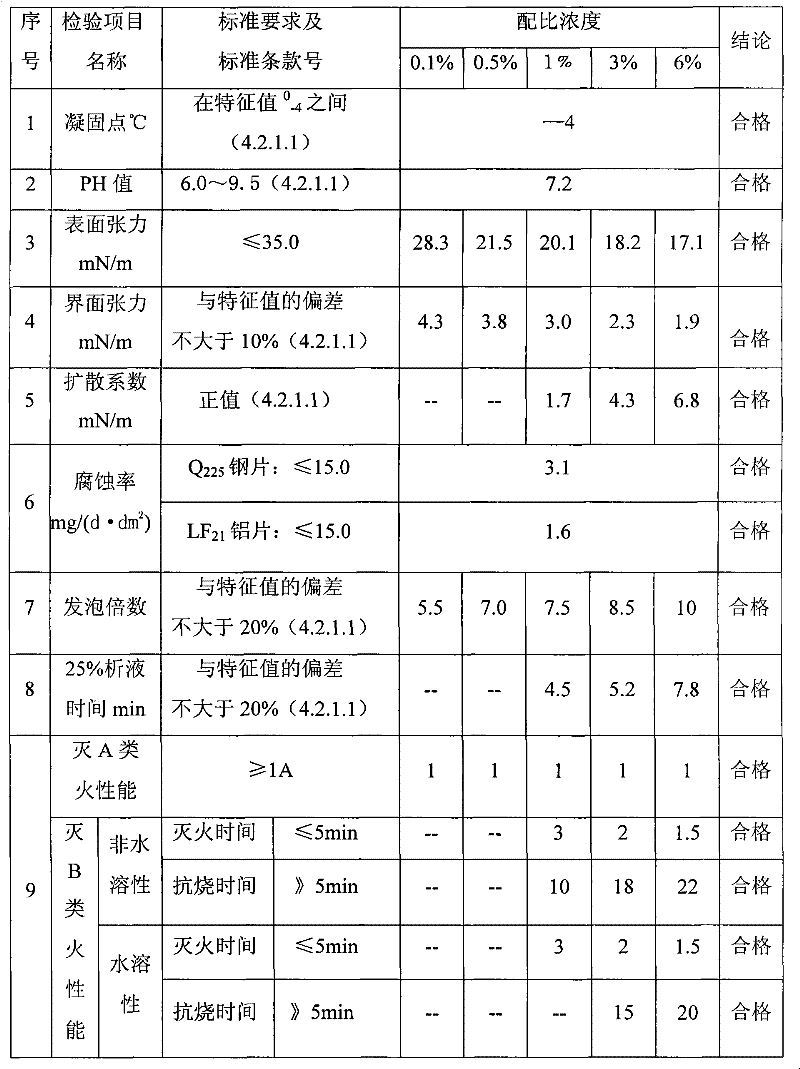

Examples

Embodiment 1

[0022] Fluorocarbon surfactant: F1268 surfactant 6%, foaming agent: K10 sodium decyl sulfate 40%, penetrating agent: JFC fatty alcohol polyoxyethylene ether 10%, flame retardant: phosphoramidite flame retardant 8 %, anti-burning agent: DuPont F1157 fluorocarbon surfactant 2%, antifreeze: glycerin 5%, cosolvent: urea 5%, pH regulator: triethanolamine 1%, purified water: 23%, by weight percentage Weigh each substance separately, mix and stir evenly to obtain the product.

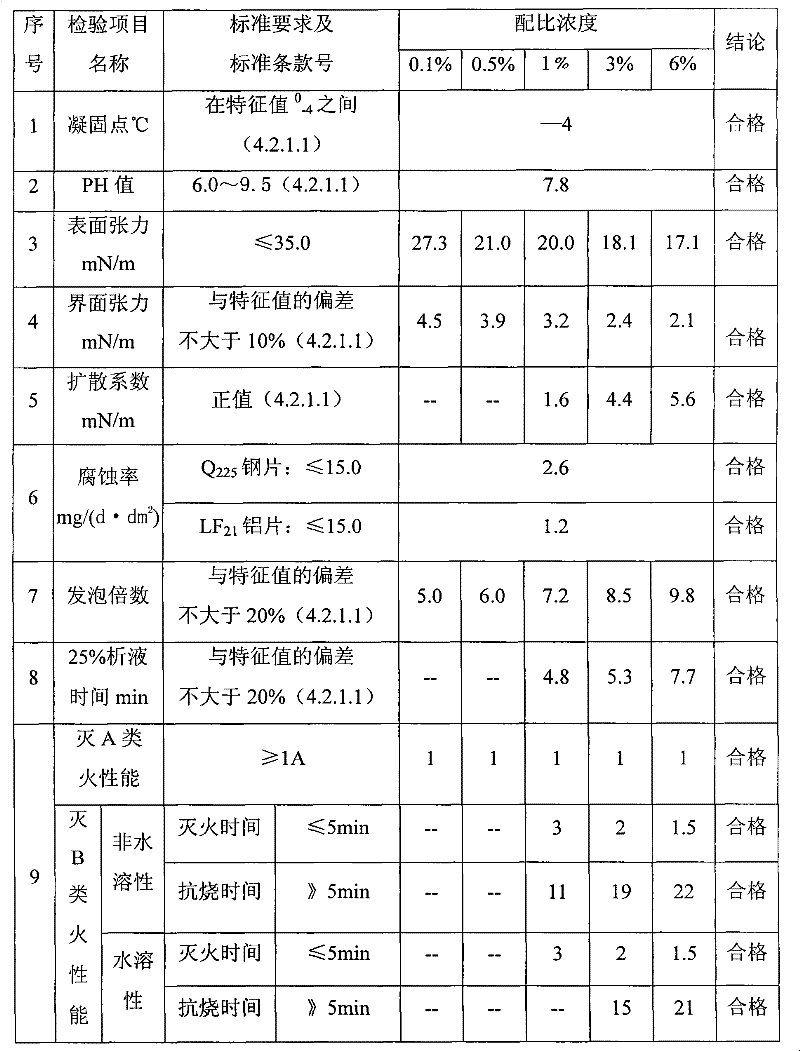

Embodiment 2

[0024] Fluorocarbon surfactant: F1268 surfactant 6%, blowing agent: K10 sodium decyl sulfate 35%, penetrating agent: JFC fatty alcohol polyoxyethylene ether 15%, flame retardant: phosphoramidite flame retardant 5 %, anti-burning agent: DuPont F1157 fluorocarbon surfactant 4%, antifreeze: glycerin 5%, cosolvent: urea 3%, pH regulator: triethanolamine 1.2%, purified water: 25.8%, by weight percentage Weigh each substance separately, mix and stir evenly to obtain the product.

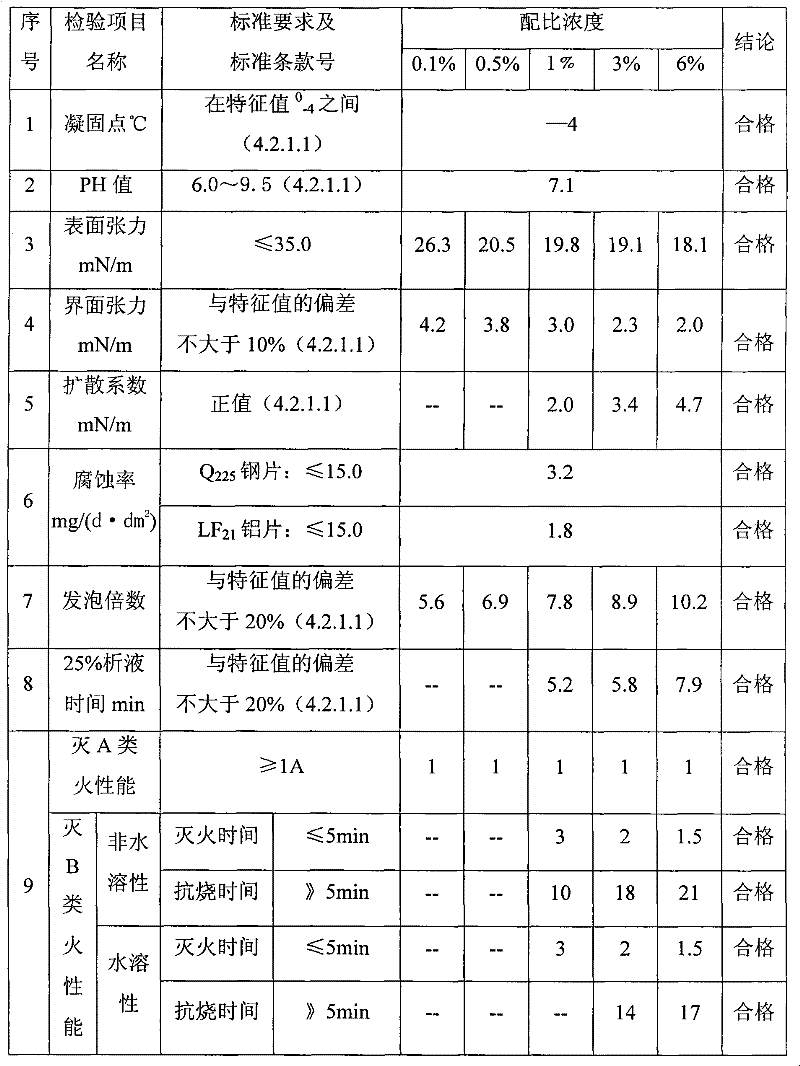

Embodiment 3

[0026] Fluorocarbon surfactant: F1268 surfactant 6%, foaming agent: K10 decyl sodium sulfate 35%, penetrant: JFC fatty alcohol polyoxyethylene ether 15%, flame retardant: phosphoramidite flame retardant 8.5 %, anti-burning agent: DuPont F1157 fluorocarbon surfactant 3.5%, antifreeze: glycerol 5%, cosolvent: urea 5%, pH regulator: triethanolamine 0.9%, purified water: 21.1%, by weight percentage Weigh each substance separately, mix and stir evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com