EP composite ultra-short curl-free fiber post-treatment production method and device

A post-processing device and fiber crimping technology, which is applied in the heat treatment of artificial filaments, complete sets of equipment for producing artificial threads, stretch spinning, etc., can solve the problems of fiber quality that cannot meet the needs of high-end markets and the level of production line equipment is not high, and achieve The effect of reducing the mixing ratio, reducing production costs, and reducing the melting point of the cortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

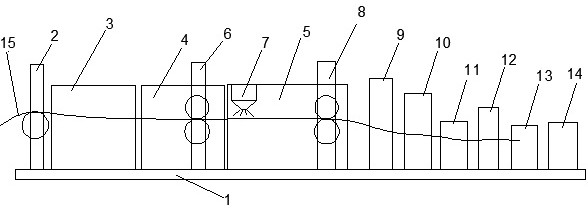

[0036] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

[0037] A post-processing production method of EP composite ultra-short non-crimp fiber, the steps of its post-processing method are as follows:

[0038] Step S1, pre-spinning strands bundled and bathed.

[0039] Step S1.1, bundle the pre-spun raw filaments according to a certain total denier of bundles, and control the tension of each filament bundle to be basically the same.

[0040] Step S1.2. Divide the total tow bundled in step S1.1 into three uniform pieces, and dip in a immersion bath with a length of 6m in hot water at 40°C to promote the relaxation of the molecular chains of the original silk and eliminate the internal stress.

[0041] Step S2, preliminary stretching of the tow.

[0042] Step S2.1. Preliminarily thermally stretch the tow after bathing in step S1.2 in hot water at 75° C. in a water bath with a length of 4 m, and the stretchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com