PE/PET composite ultra-short curl-free fiber precursor production method and device

A technology for crimping fibers and production methods, applied in fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon, etc., can solve the problem of insufficient PE/PET fiber talent aggregation, fiber quality can not meet high-end market demand, PE /PET fiber is less and other problems, to achieve the effect of reducing production cost, reducing the proportion of mixing, and increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

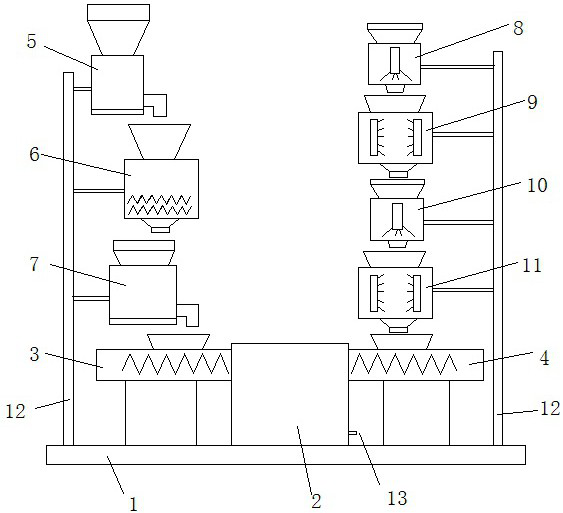

Image

Examples

Embodiment 1

[0030] PE / PET composite ultra-short non-crimp fiber precursor production method, comprises the steps:

[0031] Step S1, raw material preparation, the raw material is composed of two components A and B:

[0032] In terms of parts by mass, component A includes: 5% molecular weight regulator and 95% HDPE. 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane was chosen as the molecular weight regulator.

[0033] In parts by mass, component B includes: PET 100%.

[0034] Step S2, preparing component A:

[0035] Step S2.1. Mix the molecular weight modifier and one-half (mass ratio) of HDPE in the raw material evenly with a weight loss weighing scale.

[0036] Step S2.2, the mixture obtained in step S2.1 is mixed and granulated by a twin-screw mixer at 240°C, and an antioxidant is added in a proportion of 0.5% during the granulation process for protection.

[0037] Step S2.3. Accurately measure the plastic particles generated in step 2.2 with a weight loss weighing scale, mix them with ...

Embodiment 2

[0047] Another PE / PET composite ultra-short non-crimp fiber precursor production method comprises the following steps:

[0048] Step S1, raw material preparation, the raw material is composed of two components A and B:

[0049] In terms of parts by mass, component A includes: 5-10% of molecular weight regulator, 90-95% of HDPE. 3,6,9-triethyl-3,6,9-trimethyl-1,4,7 triperoxynonane was selected as the molecular weight regulator.

[0050] In parts by mass, component B includes: PET 100%.

[0051] Step S2, preparing component A:

[0052] Step S2.1. Mix the molecular weight modifier and one-sixth of the HDPE in the raw material evenly with a weight loss weighing scale.

[0053] Other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com