Antibacterial fiber

A technology of antibacterial fibers and raw materials, applied in the field of fibers, can solve the problems of unstable antibacterial effect and short antibacterial time, and achieve the effect of improving effect, good effect and high effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

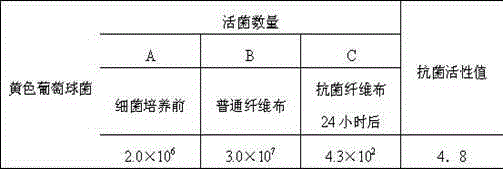

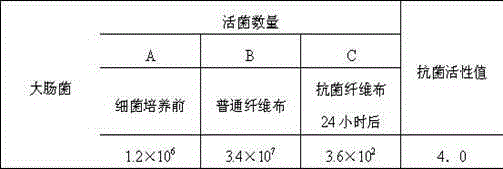

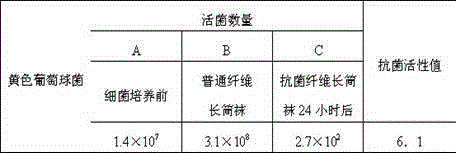

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of antibacterial fiber, this fiber is made of antibacterial fiber masterbatch after the raw material of following percentage by weight is mixed uniformly and then melt spinning is made:

[0025] Silver oxide powder or silver nitrate powder 1%;

[0026] Any one of polybutylene terephthalate, polyamide, polypropylene, polyethylene 0.5%;

[0027] Polyethylene terephthalate 98.5 %.

[0028] The methods for preparing antibacterial fiber masterbatch and melt spinning can adopt the conventional methods of fiber masterbatch and melt spinning in the prior art.

Embodiment 2

[0029] Embodiment 2, a kind of antibacterial fiber, this fiber is made of antibacterial fiber masterbatch after the raw material of following percentage by weight is mixed uniformly and then melt spinning is made:

[0030] Silver oxide powder or silver nitrate powder 15%;

[0031] Any one of polybutylene terephthalate, polyamide, polypropylene, polyethylene 5%;

[0032] Polyethylene terephthalate 80%.

Embodiment 3

[0033] Embodiment 3, a kind of antibacterial fiber, this fiber is made by melt spinning after the raw material of following percentage by weight is mixed uniformly to make antibacterial fiber master batch:

[0034] Silver oxide powder or silver nitrate powder 8%;

[0035] One or more of polybutylene terephthalate, polyamide, polypropylene, polyethylene 1.5%;

[0036] Polyethylene terephthalate 90.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com