Special composite cementitious material for high-grade concrete of bridge expansion joints and thin-shell structures

A thin shell structure and expansion joint technology, applied in the field of cement, can solve the problems of small dosage, worsening driving conditions, low quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is specifically described below in conjunction with examples.

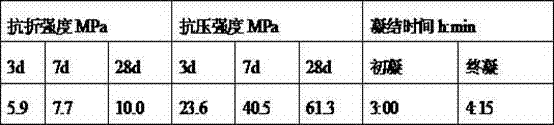

[0015] 1. Concrete for bridge expansion joints, bridge decks, and anti-collision walls shall comply with C60 requirements, and the strength grade of special high-performance composite cementitious materials shall be 62.5MPa. The weight ratio of each component in the present invention is: the general Portland cement clinker is 40%, the sum of natural gypsum and desulfurized gypsum is 5%; the rest is admixture, accounting for 45%, which can be fly ash, One or more of slag powder and volcanic ash, if all are used, specifically slag powder is 35%, volcanic ash is 5%, and the sum of silica fume and fly ash is 15%.

[0016] The requirements for each component are:

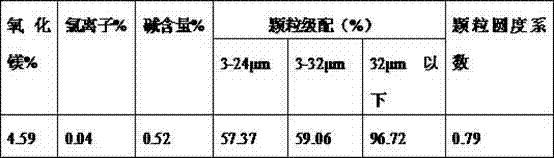

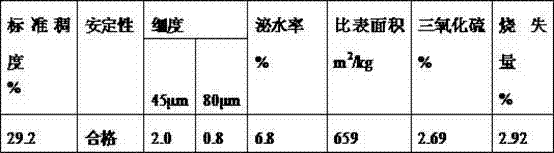

[0017] 1. General-purpose Portland cement clinker has free calcium oxide ≤ 1.5% and alkali content ≤ 0.8% before grinding. Compressive strength 3d≥28MPa, 28d≥58MPa. Specific surface area of clinker powder after grinding > 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com