Continuous solvent-free aqueous polyurethane dispersion of sulfonate, and preparation method thereof

A water-based polyurethane dispersion technology, which is applied in the field of sulfonate water-based polyurethane dispersions, can solve the problems of small molecular weight solvents for water-based polyurethane dispersions, no urea-based structural reactions, and the inability to truly prepare water-based polyurethane dispersions, etc., to achieve production The effect of efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

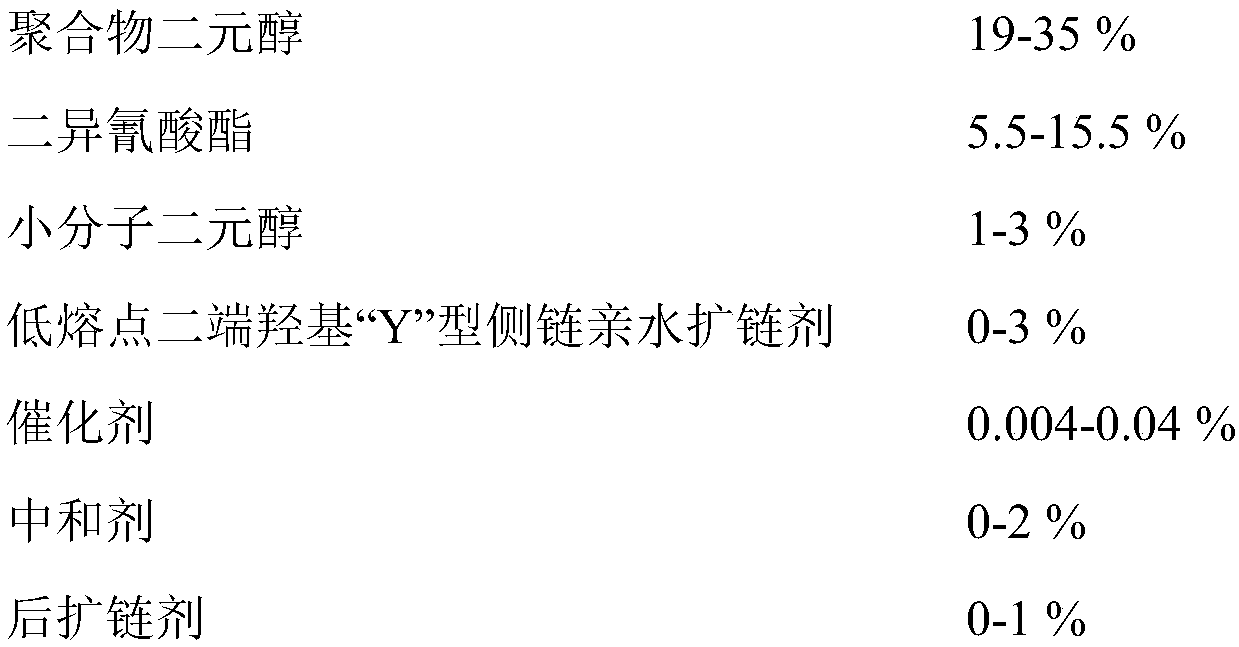

[0047] Formula: (mass percentage)

[0048]

[0049] Preparation:

[0050] (1) Mix polytetrahydrofuran diol (Mn=2000), dimethylolbutyric acid, and 2-methylol-1,3-propanediol to 80°C, add catalyst stannous octoate, and 4,4-diphenylmethane Diisocyanate (MDI) is heated up to 80°C, and the above two are injected through the gear metering pump and flow meter respectively, and the mixing head is injected at a speed of 250rpm, L / D=45, and the temperature is 120°C, 120°C, 130°C, and 140°C respectively. , Twin-screw reactors at 150°C, 170°C, and 215°C, with a residence time of 0.5min;

[0051] (2) Inject the melt gear pump into the shear pump at a temperature of 150°C and a speed of 1500rpm, and at the same time inject deionized water at a temperature of 150°C and a pressure of 0.5Mpa into the shear pump, and shear for 4 minutes;

[0052] (3) After being cooled to 30°C by a heat exchanger and decompressed to normal pressure, it is collected in a stainless steel storage tank, and st...

Embodiment 2

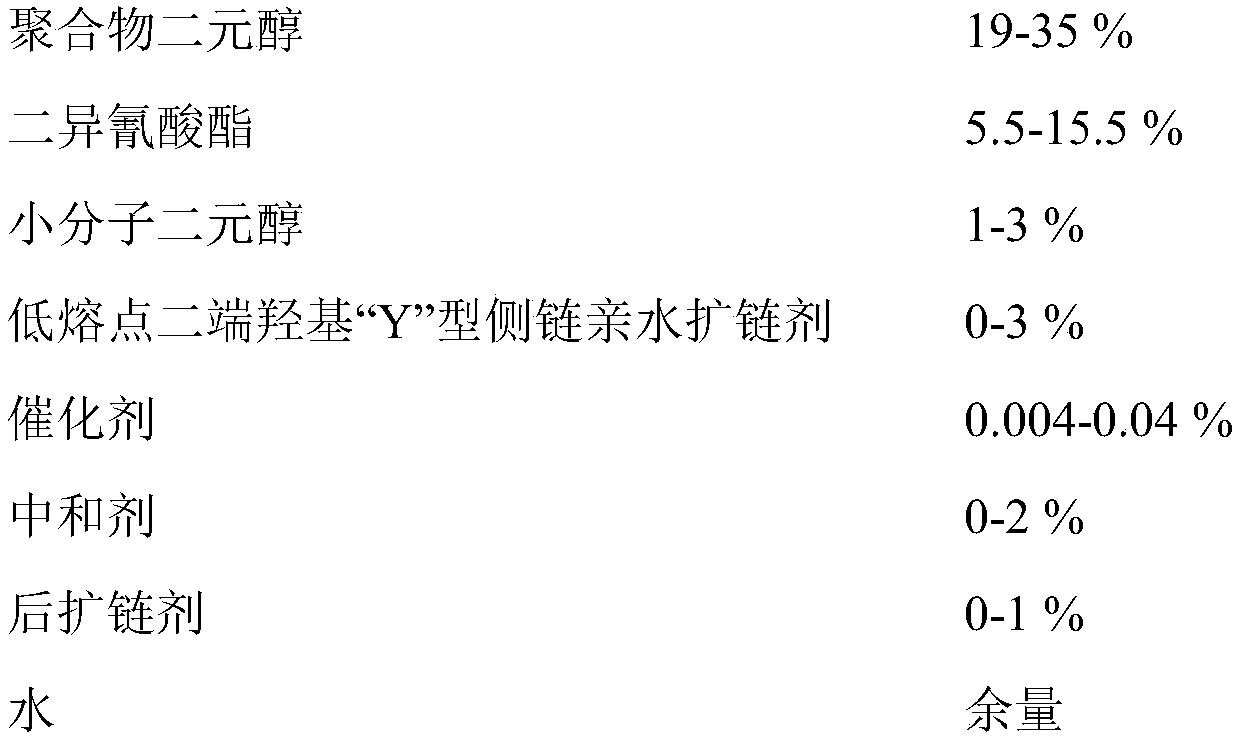

[0054] Formula: (mass percentage)

[0055]

[0056]

[0057] Preparation:

[0058] (1) Polyoxyethylene diol (Mn=500), polyadipate-1,4-butylene glycol ester diol (Mn=4000), dimethylol propionic acid, 1,4-butanediol Alcohol is mixed to 90°C, catalyst stannous octoate is added, toluene diisocyanate (TDI) is heated to 90°C, and the above two are respectively injected through the gear metering pump and flow meter through the mixing head at a speed of 250rpm, L / D=50, temperature Twin-screw reactors at 120°C, 120°C, 130°C, 140°C, 150°C, 170°C, and 215°C respectively, with a residence time of 2 minutes;

[0059] (2) Inject the melt gear pump into the shear pump with a temperature of 120°C and a speed of 1500rpm, and inject deionized water with a temperature of 120°C and a pressure of 0.2Mpa into the shear pump, and shear at a high speed for 5 minutes;

[0060] (3) Cool down to 50°C through a heat exchanger, reduce the pressure to normal pressure, and collect it in a stainless ...

Embodiment 3

[0062] Formula: (mass percentage)

[0063]

[0064] Preparation:

[0065] (1) Mix polyadipate-1,4-butylene glycol ester diol (Mn=1000), 1,4-dihydroxybutane-2-sodium sulfonate, and 1,4-butanediol to 100 ℃, add the catalyst dibutyltin dilaurate, hydrogenate 4,4-diphenylmethane diisocyanate (HMDI) and heat up to 100 ℃, the above two are injected through the mixing head through the gear metering pump and the flow meter respectively. The speed is 250rpm, L / D=30, twin-screw reactors with temperatures of 120°C, 120°C, 130°C, 140°C, 150°C, 170°C, and 215°C respectively, with a residence time of 1 min;

[0066] (2) Inject the melt gear pump into the shear pump with a temperature of 200°C and a speed of 1500rpm, and at the same time deionized water with a temperature of 200°C and a pressure of 1.5Mpa is also injected into the shear pump, and shear at a high speed for 3 minutes;

[0067] (3) The temperature was lowered to 30° C. by a heat exchanger, the pressure was lowered to norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com