Solvent-free aqueous polyurethane dispersion and its preparation method and application

A water-based polyurethane and solvent-free technology, which is applied in the field of solvent-free water-based polyurethane dispersion and its preparation and application, can solve the problem of no reaction involving urea group structure, small molecular weight solvent of water-based polyurethane dispersion, and the inability to really prepare water-based polyurethane dispersion, etc. problems, to achieve the effect of improving market competitiveness, product quality and batch stability, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

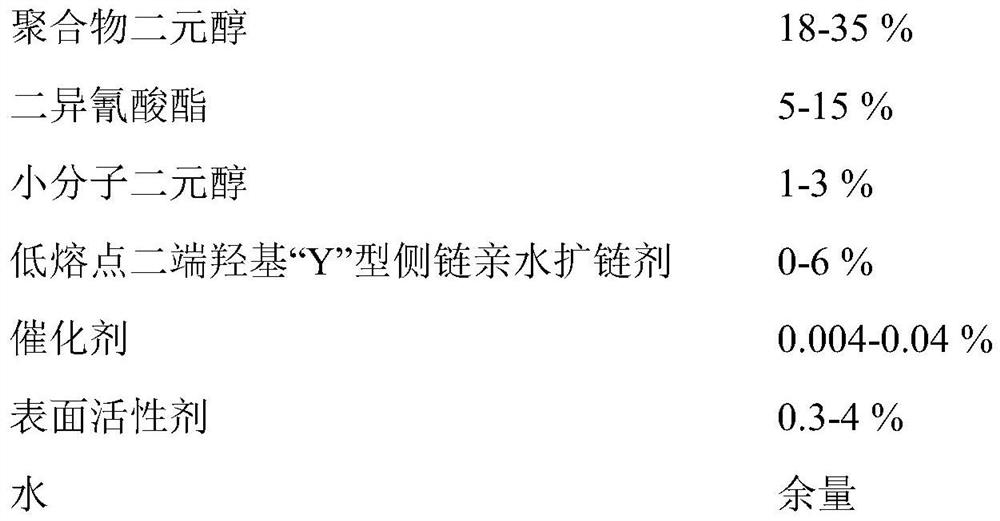

[0045] Formula: (mass percentage)

[0046]

[0047]

[0048] Preparation:

[0049] Mix and heat polytetrahydrofuran diol (Mn=2000), 2-polyethylene glycol monomethyl ether-1,4-butanediol (Mn=1000), 2-methyl-1,3-butanediol to 80 ℃, add the catalyst stannous octoate, 4,4-diphenylmethane diisocyanate (MDI) is heated to 80 ℃, the above two are respectively passed through the gear metering pump, flow meter, and after passing through the mixing head, the injection speed is 250rpm, L / D= 45. React in twin-screw reactors with temperatures of 120°C, 130°C, 140°C, 150°C, 150°C, 160°C, and 210°C, and the residence time is 0.5min;

[0050] Through the melt gear pump, it is injected into the shear pump with a temperature of 150°C and a speed of 1500rpm. At the same time, a solution of sodium cetyl sulfate with a temperature of 150°C, a pressure of 0.5Mpa, and a concentration of 0.5%wt is also injected into the shear pump. 4min;

[0051] The temperature was lowered to 30° C. by a hea...

Embodiment 2

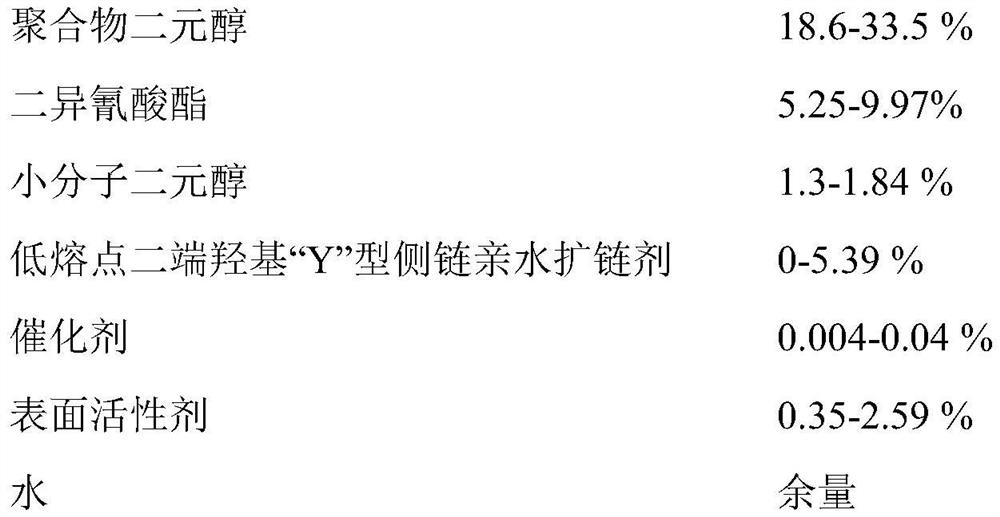

[0054] Formula: (mass percentage)

[0055]

[0056] Preparation:

[0057] Mix and heat polytetrahydrofuran diol (Mn=4000), polyethylene oxide diol (Mn=1000), and 1,4-butanediol to 60°C, add catalyst stannous octoate, and heat up toluene diisocyanate (TDI) to 60°C, the above two are respectively passed through the gear metering pump, flow meter, and then through the mixing head. , Reaction in a twin-screw reactor at 215°C, with a residence time of 2 minutes;

[0058] The melt gear pump is injected into the shear pump with a temperature of 120°C and a rotational speed of 2500rpm. At the same time, a solution of sodium cetyl sulfate with a temperature of 120°C, a pressure of 0.2Mpa, and a concentration of 2%wt is also injected into the shear pump. Cut for 5 minutes;

[0059] The temperature was lowered to 50° C. by a heat exchanger, the pressure was lowered to normal pressure, and collected in a stainless steel storage tank. After the collection was full, it was stirred for...

Embodiment 3

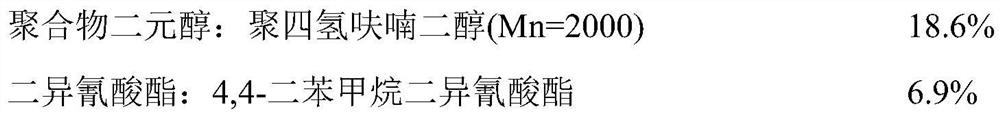

[0061] Formula: (mass percentage)

[0062]

[0063] Preparation:

[0064] Mix polyadipate-1,4-butanediol (Mn=4000), 2-polyethylene glycol monomethyl ether-1,4-butanediol (Mn=2000) and ethylene glycol and heat To 100°C, add the catalyst dibutyltin dilaurate, isophorone diisocyanate (IPDI) and hydrogenated 4,4-diphenylmethane diisocyanate (HMDI) at a molar ratio of 1:2 and raise the temperature to 100°C, the above two Through the gear metering pump and flowmeter respectively, after passing through the mixing head, inject into the twin-screw with a rotation speed of 250rpm, L / D=50, and temperatures of 100°C, 120°C, 130°C, 140°C, 170°C, 200°C, and 230°C. Reactor reaction, residence time is 1.5min;

[0065] The melt gear pump is injected into the shear pump at a temperature of 200°C and a speed of 1500rpm. At the same time, the temperature is 200°C, the pressure is 1.5Mpa, and the concentration is 1%wt sodium dodecylbenzenesulfonate solution also flows at 150kg / h In the shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com