Comprehensive recycling method of cyanide tailing slag

A technology for cyanidation of tailings and tailings, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as large fluctuations in raw material grades, environmental hidden dangers, and poor operation stability of acid production systems, and achieve efficient separation and recovery. , reducing pollution and improving comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

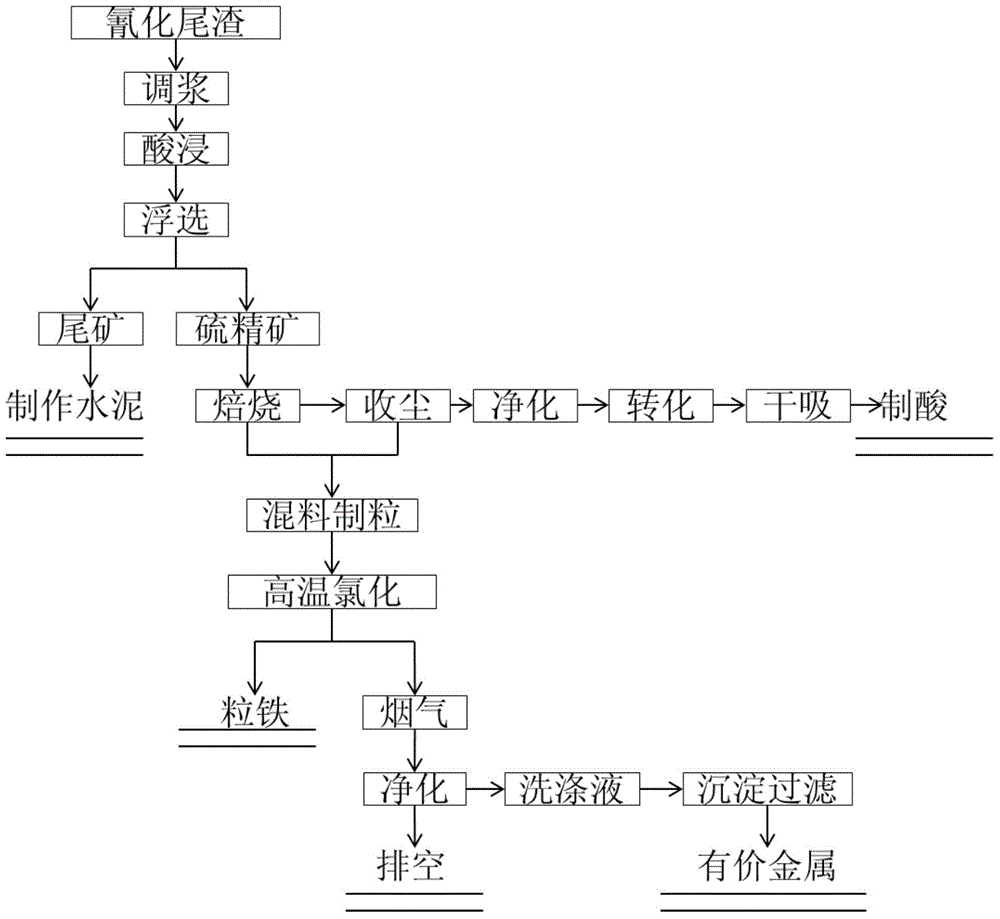

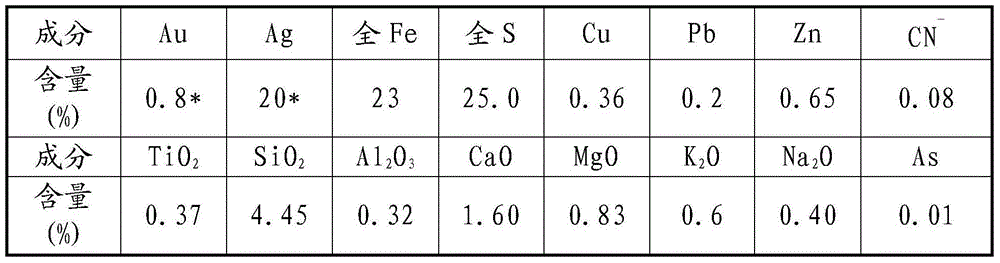

[0053] A method for comprehensive recovery and utilization of cyanide tailings, comprising the following steps:

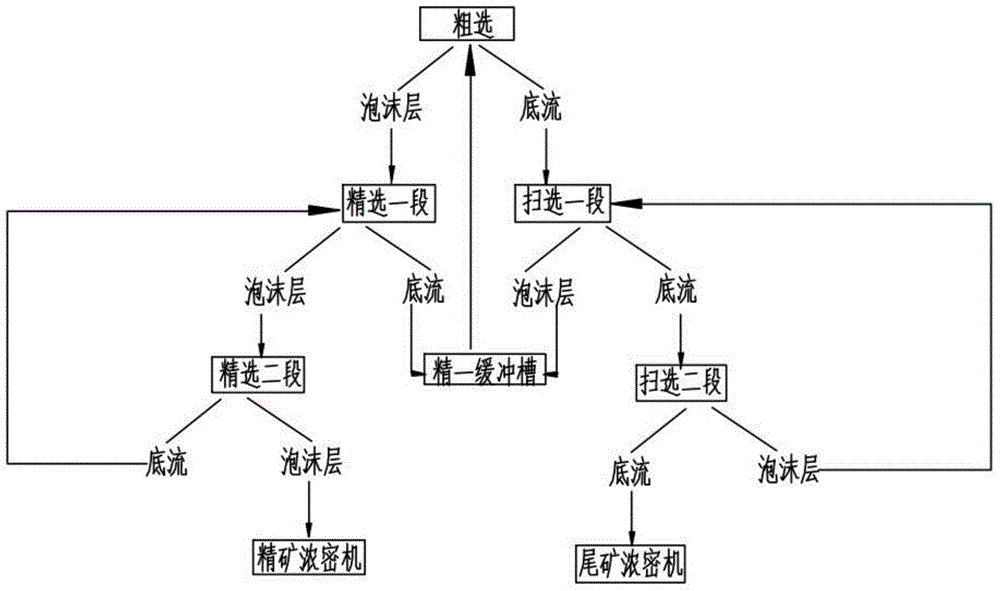

[0054] (1) Flotation to obtain high-sulfur concentrate: add water to the cyanide tailings to make it into pulp, adjust the total mass of solute in the pulp to account for 31% of the total mass of the pulp, add acid to adjust the pH of the pulp to 5, and use 450L / h Collectors are added at a high speed, and the sulfur concentrate and tailings are obtained after a roughing, a second beneficiation, and two sweepings. After the sulfur concentrate and tailings are concentrated and filtered, the tailings are used to make bricks or cement ;

[0055] (2) Acid production: After the sulfur concentrate obtained in step (1) is naturally dried to a water content of 8-10%, the sulfur concentrate is put into a roasting furnace at a rate of 15t / h, and the fluidizing air is introduced into the roasting furnace for weak Oxygen roasting, the roasting temperature is 850°C, the roastin...

Embodiment 2

[0060] A method for comprehensive recovery and utilization of cyanide tailings, comprising the following steps:

[0061] (1) Flotation to obtain high-sulfur concentrate: add water to the cyanide tailings to make it into a pulp, adjust the total mass of solute in the pulp to account for 33% of the total mass of the pulp, add acid to adjust the pH of the pulp to 5, and use 450L / h Collectors are added at a high speed, and the sulfur concentrate and tailings are obtained after a roughing, a second beneficiation, and two sweepings. After the sulfur concentrate and tailings are concentrated and filtered, the tailings are used to make bricks or cement ;

[0062] (2) Acid production: After the sulfur concentrate obtained in step (1) is naturally dried to 8-10% water content, the sulfur concentrate is put into the roasting furnace at a rate of 20t / h, and the fluidizing air is fed into the roasting furnace for weak Oxygen roasting, the roasting temperature is 900°C, the roasting linear...

Embodiment 3

[0067] A method for comprehensive recovery and utilization of cyanide tailings, comprising the following steps:

[0068] (1) Flotation to obtain high-sulfur concentrate: add water to the cyanide tailings to make it into a pulp, adjust the total mass of solute in the pulp to account for 35% of the total mass of the pulp, add acid to adjust the pH of the pulp to 6, and use 450L / h Collectors are added at a high speed, and the sulfur concentrate and tailings are obtained after a roughing, a second beneficiation, and two sweepings. After the sulfur concentrate and tailings are concentrated and filtered, the tailings are used to make bricks or cement ;

[0069] (2) Acid production: After the sulfur concentrate obtained in step (1) is naturally dried to 8-10% of water content, the sulfur concentrate is put into the roasting furnace at a rate of 16t / h, and the fluidizing air is fed into the roasting furnace for weakening Oxygen roasting, the roasting temperature is 950°C, the roastin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com