Water permeable brick based on graphene and solid wastes and preparation method thereof

A graphene and waste technology, applied in the field of permeable bricks and its preparation, can solve the problems of low comprehensive utilization efficiency of urban sludge, high energy demand, complex process, etc., to prevent environmental biological poisoning and structural damage, and to achieve good water permeability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

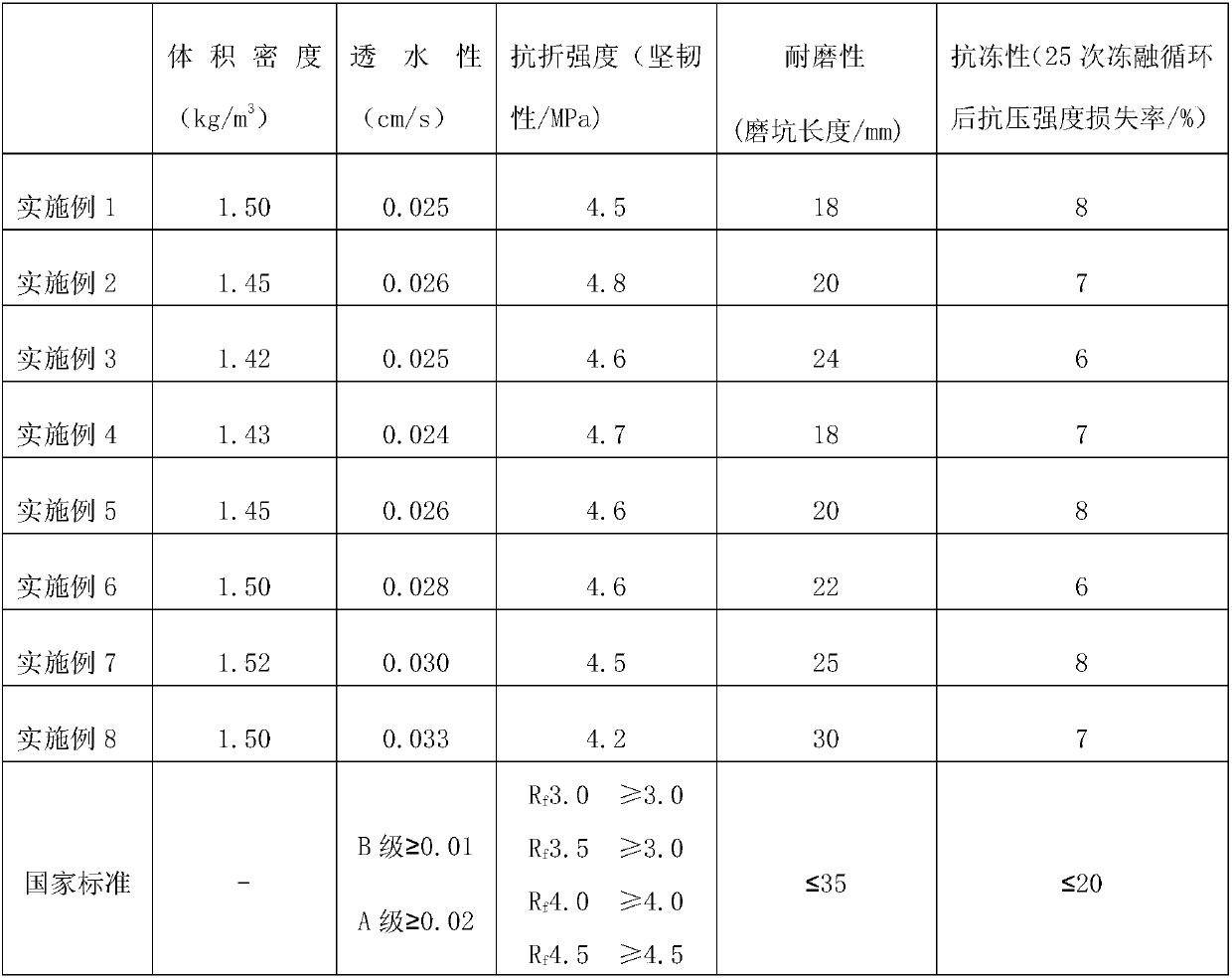

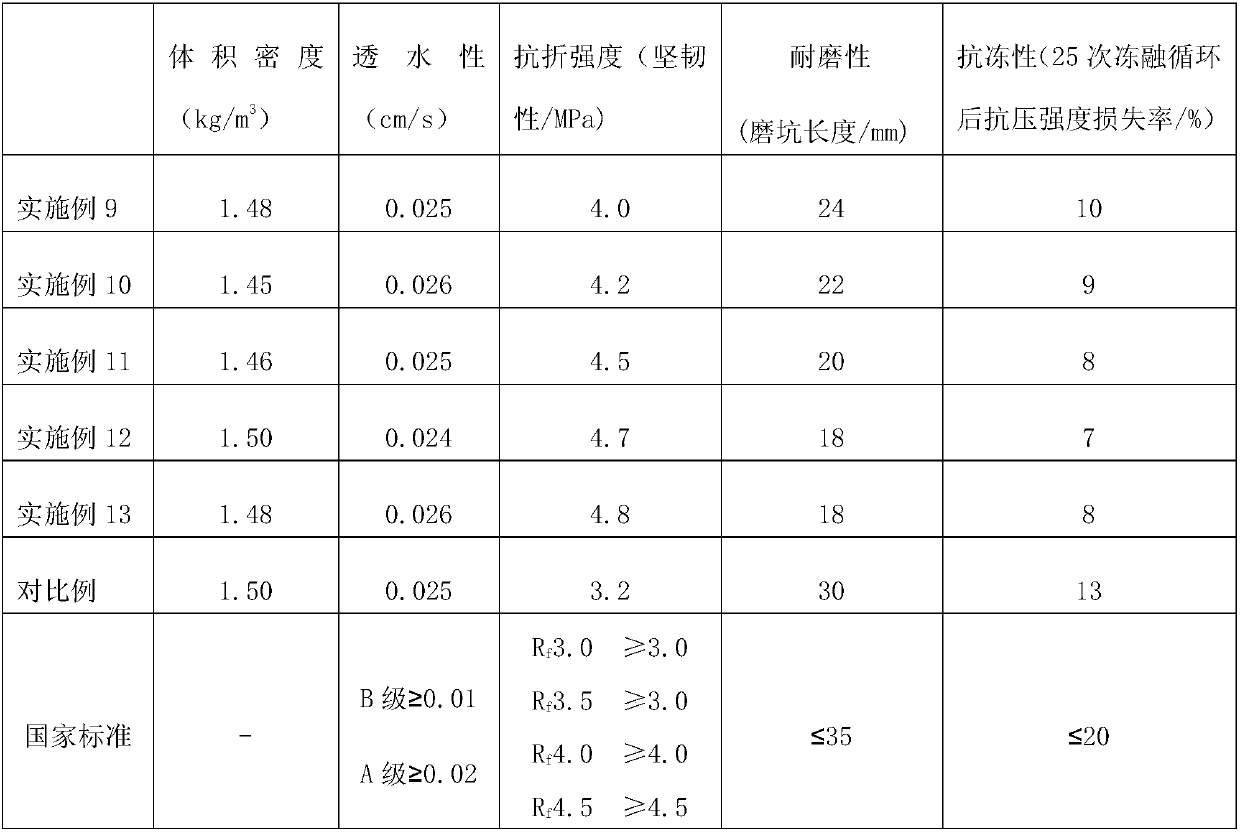

Examples

Embodiment 1

[0041] A permeable brick based on graphene and solid waste, made of the following components by weight percentage:

[0042] 15% of urban sludge, 10% of urban spoil, 15% of construction waste, 15% of fly ash, 5% of pore-forming agent, 10% of non-metallic tailings, 10% of graphene, 5% of bentonite, 10% of water glass, Pore-forming agent 4%, hydroxypropyl methylcellulose 1%.

[0043] The non-metallic tailings are granite tailings; the pore-forming agent is diatomite.

[0044] The preparation method of the permeable brick of described graphene and solid waste, comprises the following steps:

[0045] S1. Prepare raw materials:

[0046] 1) Weigh the materials according to the mass percentage of each raw material, add the urban sludge into medical stone equivalent to 10% of the sludge weight, and 2% sodium hypochlorite, mix and stir evenly, and store for 3 to 7 days to make the moisture content up to 60%.

[0047] 2) Crushing and granulating urban spoil and construction waste, th...

Embodiment 2

[0056] A permeable brick based on graphene and solid waste, made of the following components by weight percentage:

[0057] 18% of urban sludge, 15% of urban spoil, 15% of construction waste, 15% of fly ash, 8% of non-metallic tailings, 7% of graphene, 5% of bentonite, 10% of water glass, 4% of pore-forming agent, Hydroxypropyl methylcellulose 1%, colorant 2%.

[0058] The non-metallic tailings are feldspar tailings. The pore-forming agent is rice husk.

[0059] The preparation method is the same as in Example 1.

Embodiment 3

[0061] A permeable brick based on graphene and solid waste, made of the following components by weight percentage:

[0062] 20% of urban sludge, 10% of urban spoil, 10% of construction waste, 15% of fly ash, 5% of non-metallic tailings, 5% of graphene, 5% of bentonite, 20% of water glass, 4% of pore-forming agent, Hydroxypropyl methylcellulose 1%, colorant 5%

[0063] The non-metallic tailings are diabase tailings and basalt tailings. The pore-forming agent is polystyrene microbeads and calcined zeolite.

[0064] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com