Dry particle glaze rock simulated ceramic tile production process

A production process, rock-like technology, applied in the production process of rock-like tiles, can solve problems such as unsatisfactory accumulation of matte dry particles, glue flowing into the glaze vat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

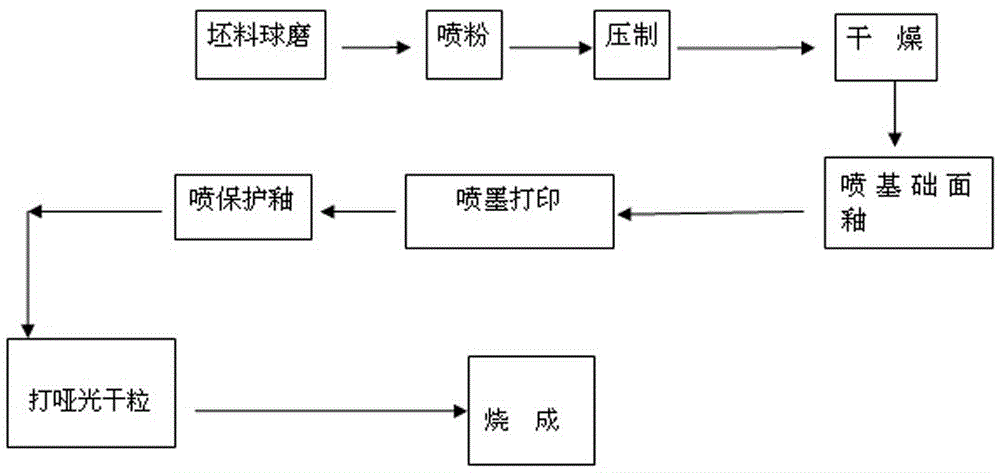

[0011] Implementation method 1: if figure 1 Shown: The steps and process requirements of the single-point product manufacturing process are as follows:

[0012] ⑴ Billet ball milling: The billet is composed of clay, sand and stone, etc., and 0.2-0.3% of magnesium chloride hexahydrate is added to control the specific gravity of the billet slurry to 1.6-1.7g / ml, the water content to 32-35%, and the flow rate to 35-75 s (The unit "s" is seconds, flow rate: refers to the time required for the slurry in the standard container to flow out), fineness 1.0-1.1 g; (fineness refers to the fixed weight slurry filtered through a 250-mesh sieve, and the sieve residue weight after drying)

[0013] (2) Powder spraying: the moisture controlled by the powder is 6-8%;

[0014] (3) Pressing: Sandstone and slate molds are used to press the ceramic tile body under the pressure of 190-200bar (bar is the pressure unit of the press, which is equivalent to ten to the fifth power pa);

[0015] ⑷ Dryi...

Embodiment approach 2

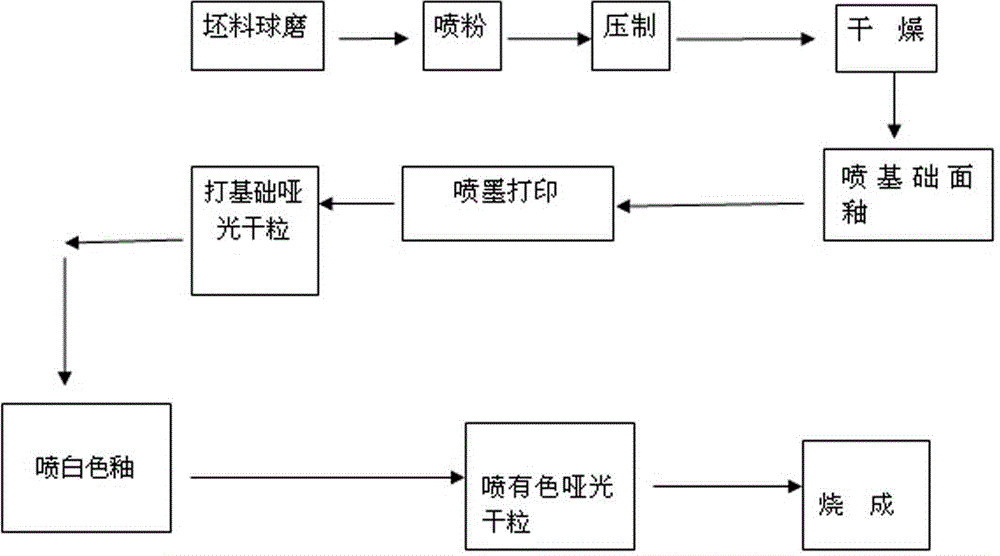

[0021] Implementation method 2: if figure 2 Shown: The steps and process requirements of the multi-point product manufacturing process are as follows:

[0022] ⑴ Billet ball milling: the billet is composed of clay, sand and stone, and 0.2-0.3% of magnesium chloride hexahydrate is added to control the density of the billet to 1.6-1.7g / ml, the moisture to 32-35%, the flow rate to 35-75s, and the fineness to 1.0- 1.1g;

[0023] (2) Powder spraying: the moisture controlled by the powder is 6-8%;

[0024] (3) Pressing: Using sandstone and slate molds, under the pressure of 190-200bar, press into the ceramic tile body;

[0025] ⑷ Drying: Dry at 60-80°C for 30-60 minutes, and control the moisture content to less than 0.05%;

[0026] ⑸Spray the basic surface glaze: use three materials: basic surface glaze, alumina slurry, water-washed ball soil slurry and debonding agent;

[0027] ⑹Inkjet printing: use inorganic ceramic ink materials;

[0028] ⑺Spray basic matte dry granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com