Polyester resin composition as well as preparation method and application thereof

A polyester resin and composition technology, applied in the field of polyester resin composition and its preparation, can solve the problems of molecular chains not being crystallized in time, insufficient molecular chain mobility, and reduced dimensional stability, etc., to achieve perfect material crystallization and improve Dimensional stability and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

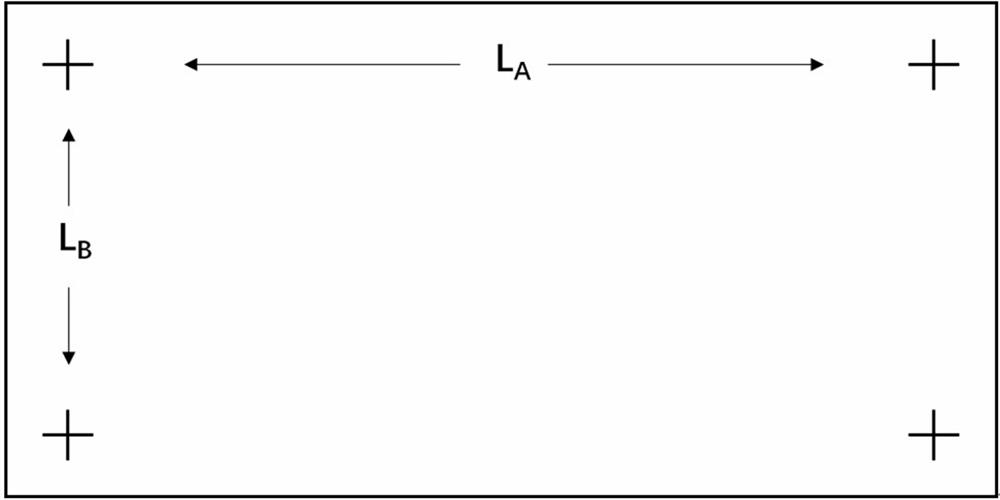

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific examples and comparative examples. The following specific examples are all preferred embodiments of the present invention, but the embodiments of the present invention are not limited by the following examples, especially not limited to The models of each component raw material used in the following specific examples.

[0025] The raw materials used in the following examples and comparative examples are derived from commercially available products.

[0026] PCT resin-A: intrinsic viscosity: 0.719 dL / g, Eastman Chemical Products (EastmanTM Chemical Products), PCT36296.

[0027] PCT resin-B: intrinsic viscosity: 0.65dL / g, SK Chemicals (SK Chemicals), 0302;

[0028] PCT resin-C: intrinsic viscosity: 0.75dL / g, SK Chemicals (SK Chemicals), 0502;

[0029] Hyperbranched polyester-A: molecular weight 920g / mol, hydroxyl value 370mg KOH / g, Wuhan Hyperbranched Resin Technology Co., Ltd.;

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com