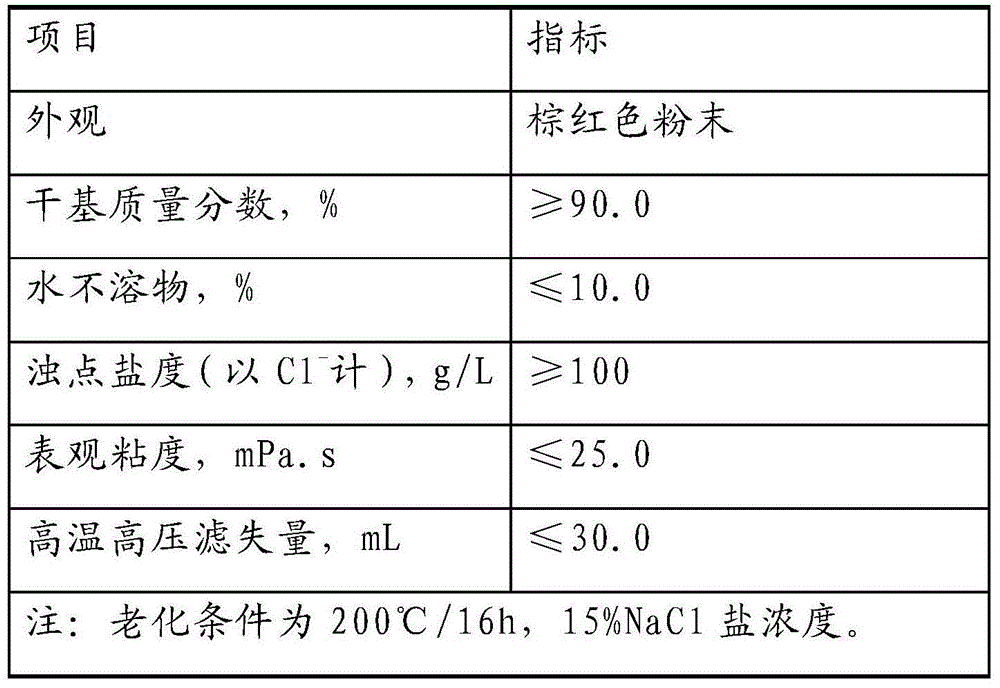

Preparation method of high-temperature-resistant modified sulfonated phenol formaldehyde resin for drilling fluids

A sulfonated phenolic resin, high temperature resistance technology, applied in the field of resin, can solve the problem of not meeting drilling needs and other problems, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

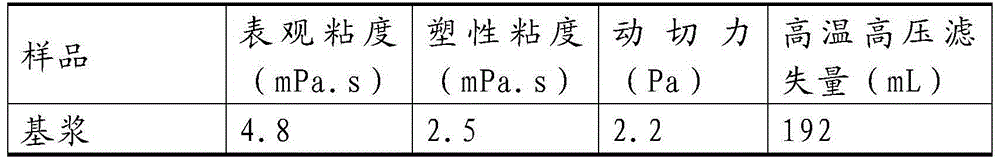

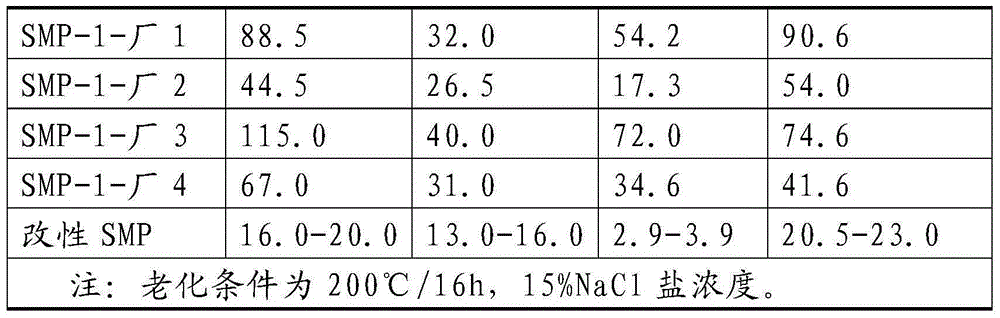

Examples

Embodiment 1

[0036] A method for preparing a high temperature resistant modified sulfonated phenolic resin for drilling fluid provided by an embodiment of the present invention comprises the following steps:

[0037] 1) Add 1 mol of phenol, 0.5 mol of formaldehyde and 0.001 mol of phosphoric acid into the reactor in sequence, mix and stir for 10 minutes, keep the temperature at 70°C, and react for 20 minutes.

[0038] 2) Dissolve 1.0 mol of sodium sulfite in 100 mL of water, and slowly add 0.5 mol of formaldehyde under stirring to prepare a sulfonating agent.

[0039] 3) After the reaction in the above step 1), add 1.0 moles of sodium hydroxide and 0.01 moles of formaldehyde, and keep the temperature at 60° C., add the sulfonating agent in the above step 2) to the reactor in batches, and continue the reaction for 100 minutes.

[0040] 4) After the reaction, cool down and discharge the material, keep the temperature of the material at 55° C., and obtain the product of Example 1 by spray dry...

Embodiment 2

[0042] A method for preparing a high temperature resistant modified sulfonated phenolic resin for drilling fluid provided by an embodiment of the present invention comprises the following steps:

[0043] 1) Add 1.0 moles of p-cresol, 1.0 moles of acetaldehyde and 0.1 moles of hydrochloric acid to the reactor in sequence, mix and stir for 10 minutes, keep the temperature at 80°C, and react for 100 minutes.

[0044] 2) Dissolve 1.0 mole of sodium bisulfite in 100 mL of water, and slowly add 1.0 mole of formaldehyde under stirring to prepare a sulfonating agent.

[0045] 3) After the reaction in the above step 1), add 0.001 mol of potassium hydroxide and 0.6 mol of acetaldehyde, and keep the temperature at 70° C., add the sulfonating agent in the above step 2) to the reactor in batches, and continue the reaction for 20 minutes.

[0046] 4) After the reaction, cool down and discharge the material, keep the temperature of the material at 65° C., and obtain the product of Example 2 ...

Embodiment 3

[0048] A method for preparing a high temperature resistant modified sulfonated phenolic resin for drilling fluid provided by an embodiment of the present invention comprises the following steps:

[0049] 1) Add 1.0 moles of p-ethylphenol, 1.0 moles of formaldehyde and 1.5 moles of acetic acid to the reactor in sequence, mix and stir for 10 minutes, keep the temperature at 80°C, and react for 300 minutes.

[0050]2) Dissolve 1.0 mol of sodium metabisulfite in 100 mL of water, and slowly add 1.0 mol of formaldehyde under stirring to prepare a sulfonating agent.

[0051] 3) After the reaction in the above step 1), add 0.5 moles of barium hydroxide and 0.7 moles of formaldehyde, and keep the temperature at 80° C., add the sulfonating agent in the above step 2) to the reactor in batches, and continue the reaction for 300 minutes.

[0052] 4) After the reaction, cool down and discharge the material, keep the temperature of the material at 75° C., and obtain the product of Example 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com