Fluid loss additive for drilling fluid and preparation method thereof

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that cannot meet the high temperature and high pressure fluid loss and rheological control, so as to improve the salt resistance, reduce the The cost of raw materials, the effect of easy reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

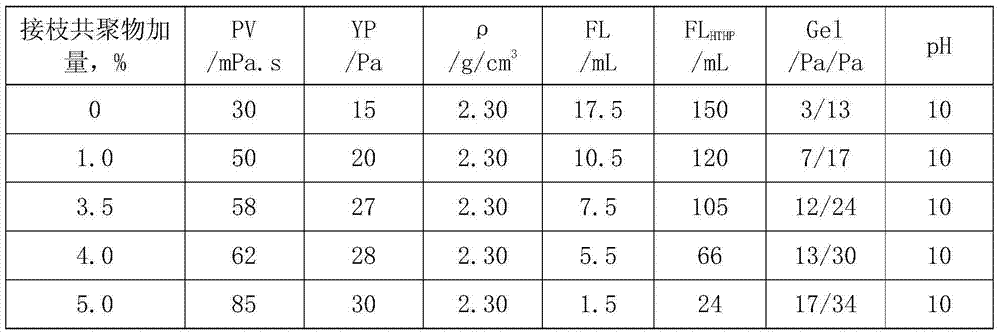

Examples

Embodiment 1

[0021] Add 320g of water, 94g of phenol, 208g of formaldehyde, 100g of sodium humate, 66.5g of sodium metabisulfite, and 88.2g of anhydrous sodium sulfite into the reactor, and react at 120°C for 8 hours to obtain a sulfonated phenolic humic acid resin; Add water and 60g of sodium hydroxide to the reaction flask. After the sodium hydroxide is dissolved and cooled, add 310.5g of AMPS, then add 140g of acrylamide and 150g of N,N-dimethylacrylamide, and stir until completely dissolved to obtain a reaction mixture of monomers The sulfonated phenolic humic acid resin solution and the reaction mixture of the monomer are mixed uniformly, add 1.8g ammonium persulfate initiator at 55 DEG C, keep reacting at this temperature for 5 hours, dry and pulverize to obtain P( AMPS-AM-AAM) / sulfonated phenolic humic acid resin graft copolymer.

Embodiment 2

[0023] Add 320g of water, 94g of phenol, 217g of formaldehyde, 110g of potassium humate, 76g of potassium pyrosulfite, and 82g of anhydrous potassium sulfite into the reactor, and react at 125°C for 7 hours to obtain a sulfonated phenolic humic acid resin; Add 550g of water and 56g of sodium hydroxide into the reaction flask. After the sodium hydroxide is dissolved and cooled, add 290g of AMPS, then add 126g of acrylamide and 140g of N,N-dimethylacrylamide, and stir until they are all dissolved to obtain the reaction of the monomer mixture. Mix the sulfonated phenolic humic acid resin solution and the monomer reaction mixture evenly, add 1.5g of ammonium persulfate initiator at 60°C, keep the reaction at this temperature for 6 hours, dry and pulverize to obtain P(AMPS -AM-AAM) / sulfonated phenolic humic acid resin graft copolymer.

Embodiment 3

[0025] Add 280g of water, 94g of phenol, 200g of formaldehyde, 95g of sodium humate, 60.8g of sodium pyrosulfite, and 107g of anhydrous sodium sulfite into the reactor, and react at 165°C for 7 hours to obtain a sulfonated phenolic humic acid resin; , 64g of sodium hydroxide was added to the reaction flask, after the sodium hydroxide was dissolved and cooled, 311g of AMPS was added, then 154g of acrylamide and 135g of N,N-dimethylacrylamide were added, and stirred until all of them were dissolved to obtain a reaction mixture of monomers; Mix the sulfonated phenolic humic acid resin solution and the monomer reaction mixture evenly, add 1.8g of ammonium persulfate initiator at 65°C, keep the reaction at this temperature for 6 hours, dry and pulverize to obtain P(AMPS- AM-AAM) / sulfonated phenolic humic acid resin graft copolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com