Polyurethane/silicone rubber hybrid material capable of 3D printing and preparation method thereof

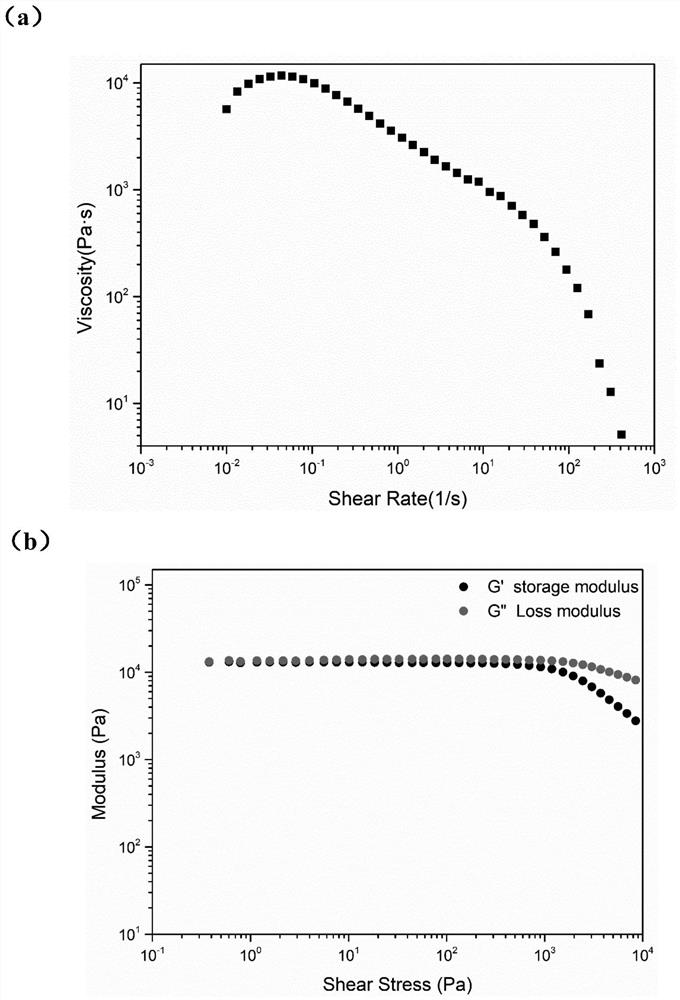

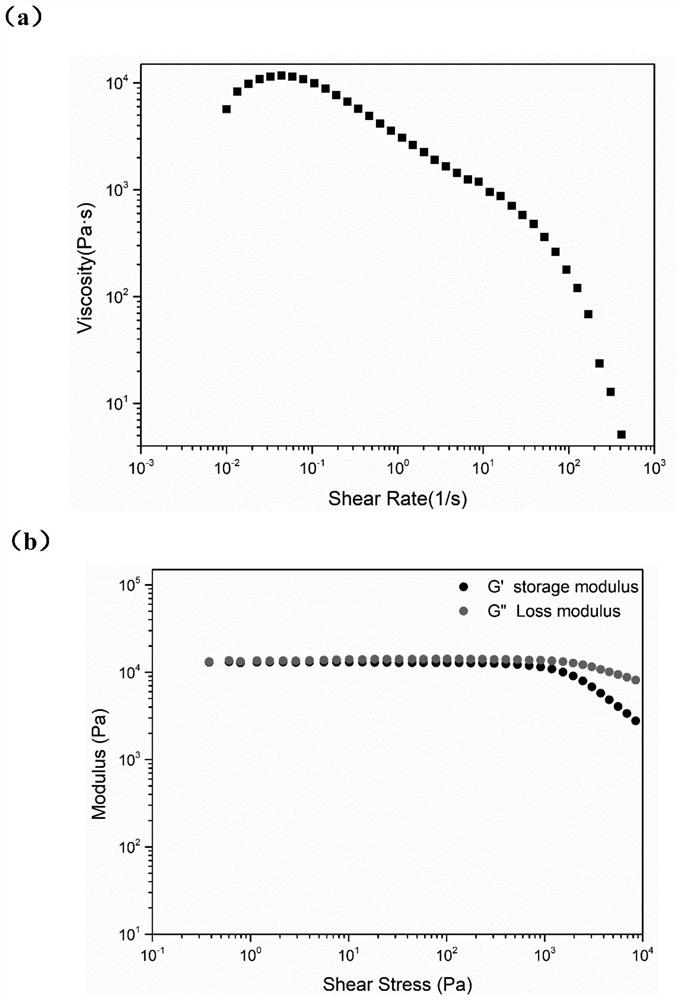

A hybrid material, polyurethane technology, applied in the direction of additive processing, can solve the problems of inability to meet the 3D printing conditions, poor mechanical properties, holes in the material, etc., and achieve the effect of good application prospects and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1. Preparation of polysiloxane polyurethane / silicon rubber hybrid material of the present invention

[0045] The preparation method of micro-crosslinked polysiloxane polyurethane is as follows:

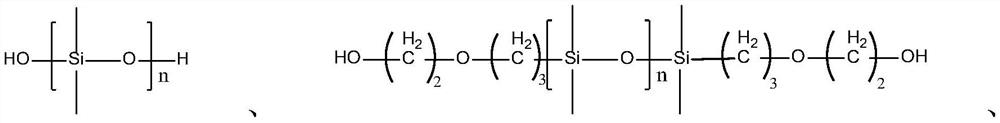

[0046] (1) Synthesis of polysiloxane polyurethane:

[0047]Raw material: hydroxyl terminated polymethylsiloxane (molecular weight 2000), H 12 Molar ratio of MDI and hydroxyethyl methacrylate: 1:1.5:1

[0048] The hydroxyl-terminated polymethylsiloxane was compounded with the catalyst organobismuth, and the H 12 In the reaction kettle of MDI, seal the reaction kettle, turn on stirring, and introduce nitrogen to carry out the following process;

[0049] The temperature was raised to 80°C and kept for 4 hours;

[0050] Lower the temperature to 50°C, slowly add hydroxyethyl methacrylate, and keep the temperature for 3 hours;

[0051] (2) Preparation of polyurethane-modified silicone with micro-crosslinked structure

[0052] A vacuum oven was used, the oxygen content w...

Embodiment 2

[0057] Example 2. Preparation of polysiloxane polyurethane material of the present invention

[0058] The preparation of the micro-crosslinked polysiloxane polyurethane is the same as that in Example 1.

[0059] The polysiloxane polyurethane (20phr) is compounded with vinyl silicone oil (100phr), hydrogen-containing silicone oil, silicon dioxide, and curing agent. The specific compounding process is as follows:

[0060] (a). Obtain vinyl silicone oil (100phr) and silicon dioxide (30phr) mixture by Banbury mixer;

[0061] (b). Polysiloxane polyurethane is mixed into the kneaded product of (a) using an open mill.

[0062] (c). Hydrogen-containing silicone oil (0.018phr), platinum catalyst (10ppm), inhibitor 3-butyn-1-ol (addition amount is 1~10% of the total mass of the compound) are mixed into the kneaded product of (b). 2%), and kneading (the temperature does not exceed 60°C) to obtain it.

Embodiment 3

[0063] Embodiment 3, the preparation of polysiloxane polyurethane material of the present invention

[0064] The preparation of the micro-crosslinked polysiloxane polyurethane is the same as that in Example 1.

[0065] The polysiloxane polyurethane (25phr) is compounded with vinyl silicone oil (100phr), hydrogen-containing silicone oil, silicon dioxide, and curing agent. The specific compounding process is as follows:

[0066] (a). Obtain vinyl silicone oil (100phr) and silicon dioxide (40phr) mixture by Banbury mixer;

[0067] (b). Polysiloxane polyurethane is mixed into the kneaded product of (a) using an open mill.

[0068] (c). Hydrogen-containing silicone oil (0.018phr), platinum catalyst (10ppm), inhibitor 3-butyn-1-ol (addition amount is 1~10% of the total mass of the compound) are mixed into the kneading material of (b). 2%), and kneading (the temperature does not exceed 60°C) to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com