Deepwater drilling fluid

A deepwater drilling and seawater technology, applied in the field of drilling fluid, can solve the problems of less environmental pollution and low cost of raw materials, and achieve the effects of less environmental damage, good rheology, and obvious hydrate inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Adopt the base slurry of 2% (1# drilling fluid), 2.5% (2# drilling fluid), 3% (3# drilling fluid) in the present embodiment, the preparation method of the drilling fluid used is as follows (in the following each embodiment Both use this drilling fluid):

[0018] At room temperature, 1# drilling fluid weighs the required raw materials according to the following amount: 3L seawater (mainly composed of sodium chloride, potassium chloride, magnesium sulfate and other salts, with a salt content of 34.4‰), 60g bentonite, 2.4g Soda ash, 3g xanthan gum XC, 30g Na-CMC (preferably viscosity 1400-2000mPa·s, degree of substitution 0.7-0.8), 60g SMP-2, 90g sodium silicate, 30g PVP-K90, 45g KAHM, 150g chloride Sodium, 1.5g DBS, 1.5g graphite, 0.6g paraformaldehyde.

[0019] 2# Drilling fluid weighs the required raw materials according to the following amount: 3L seawater (mainly composed of sodium chloride, potassium chloride, magnesium sulfate and other salts, with a salt content o...

Embodiment 2

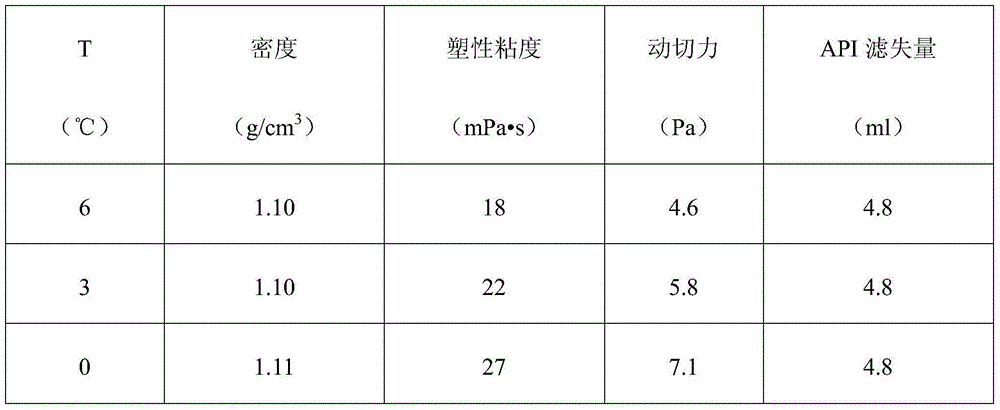

[0023] According to domestic and foreign marine drilling practices, it is generally advisable to control the circulating temperature of drilling fluid in the range of 0-6°C during deepwater drilling. In order to test the characteristics of the drilling fluid at low temperature, the temperature in this example is selected to measure the conventional performance of the three drilling fluids developed in the range of -6-6°C, so as to evaluate the performance of the drilling fluid at low temperature. The instruments used in this embodiment include a digital display liquid density meter, a rotational viscometer, a fluid loss tester, and the like.

[0024] Table 1 Conventional properties of 1# drilling fluid at different temperatures

[0025]

[0026]

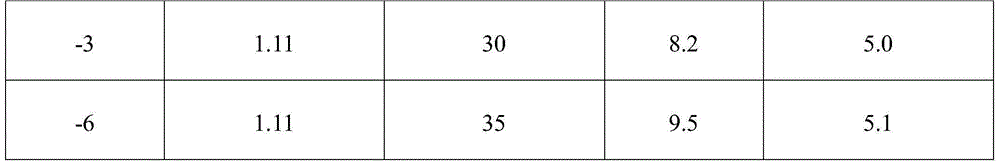

[0027] Table 2 Conventional properties of 2# drilling fluid at different temperatures

[0028]

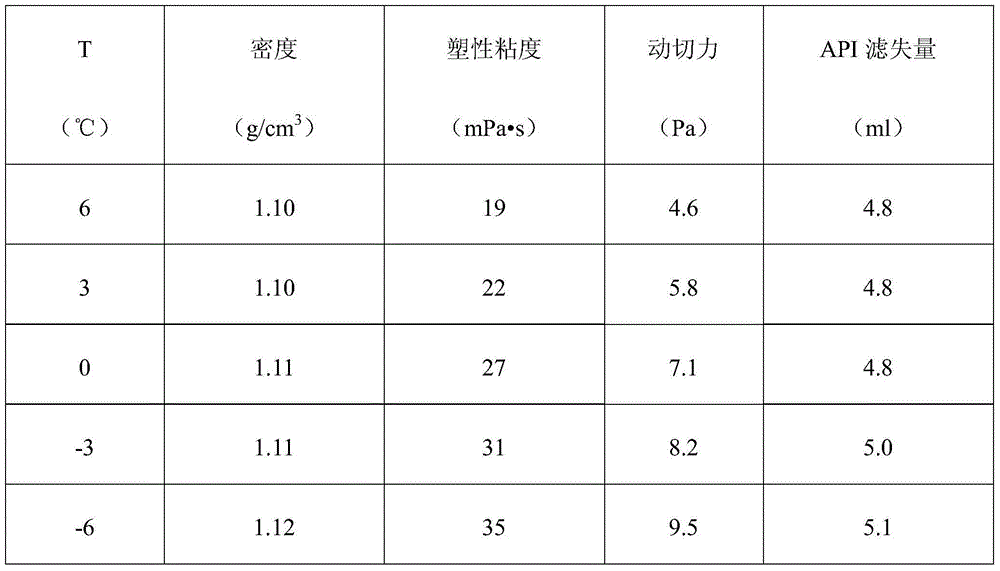

[0029] Table 3 Conventional properties of 3# drilling fluid at different temperatures

[0030]

[0031]

[0032] It can...

Embodiment 3

[0034] In the process of deepwater drilling, deepwater formations often contain large sections of shale and other unstable rock formations. During the drilling process, if the filtration loss of drilling fluid is large, the shale is easy to hydrate and expand, resulting in instability of the wellbore. lead to drilling accidents. In this example, shale samples were soaked in the above-prepared drilling fluids, and their linear expansion rate was tested by a shale dilatometer to evaluate whether the above drilling fluids had good shale hydration inhibition. The measurement was carried out in the temperature range of 0-6° C., and the experiment time was 24 hours. The measurement results are as follows.

[0035] Table 4. Linear expansion test results of 1# drilling fluid mud shale at different temperatures

[0036]

[0037]

[0038] Table 5. Linear expansion test results of shale with 2# drilling fluid at different temperatures

[0039]

[0040] Table 6. Linear expansio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com