Preparation method of sulfonated bisphenol A-formaldehyde condensate superplasticizer

A technology of formaldehyde condensate and high-efficiency water reducer, which is applied in the field of high-efficiency water reducer and production, can solve the problems of human harm and environmental pollution, and achieve the effects of saving material costs, reducing sewage costs, and saving investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 2:

Embodiment 2

[0023] Embodiment 3:

Embodiment 3

[0025]

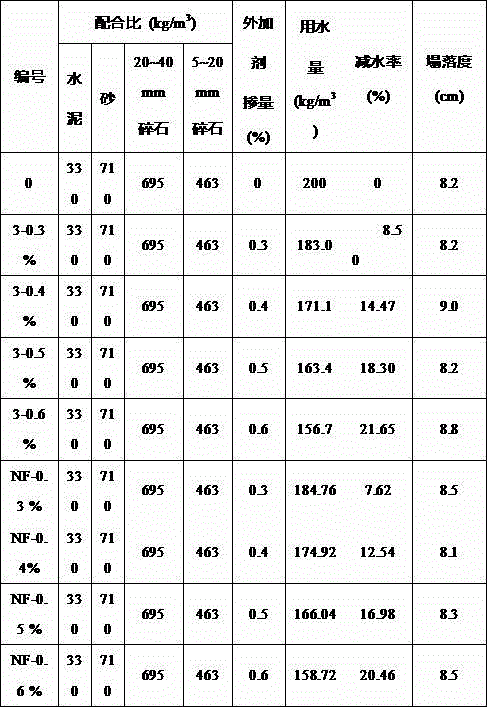

[0026] Embodiment 3 is a preferred embodiment of the present invention. The water-reducing rate and strengthening effect of the sulfonated bisphenol A-formaldehyde condensate high-efficiency water-reducer of Test Example 3 in concrete is measured in the test from 0.3-0.6% The water reducing rate of the sulfonated bisphenol A-formaldehyde condensate high-efficiency superplasticizer, and compared with the test results of the water-reducing rate of the naphthalenesulfonate high-efficiency superplasticizer (NF) at the same dosage, the concrete mix ratio used in the experiment is shown in the table 1. The cement is Jiangnan-Onoda PⅡ grade 52.5 Portland cement, the sand rate is 36-40%, the crushed stone is the second grade, 5-20mm crushed stone accounts for 40%, 20-40mm crushed stone accounts for 60%, and the concrete slump is controlled The slump is 7-9cm, the admixture is liquid, calculated by weight percentage of cement:

[0027] Table 1. The mix ratio of the concrete u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com